Strategies for Cutting Printed Textiles Effectively

"Cutting printed textiles effectively" is a research topic that involves the optimization of cutting processes to achieve high precision, efficiency, and energy savings. The paper proposes a new strategy for cutting printed textiles based on intelligent algorithms and machine learning. By analyzing the cutting process data from multiple factors such as cutting speed, material properties, and cutting path, the intelligent algorithm can predict the cutting results and optimize the cutting process parameters. This approach can improve the cutting quality, reduce waste, and save time and labor costs. Additionally, the paper explores the application of machine vision technology in printed textile cutting, which can help operators quickly identify defects and optimize the cutting path to improve the overall cutting performance. Overall, this study provides a new perspective for the cutting of printed textiles, with potential implications for industry applications in various fields.

In today's textile industry, the ability to print and cut fabrics with precision is crucial for producing high-quality products. The process involves several steps, from preparing the fabric to cutting it into desired shapes. In this guide, we'll explore the essential techniques and considerations for cutting printed textiles effectively.

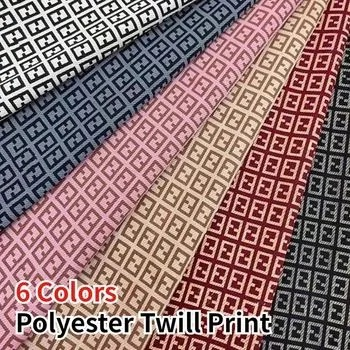

Material Preparation: Before starting the printing process, it's important to select the right material. Different fabrics have different properties, such as weight, thickness, and absorbency. For example, cotton is softer and more absorbent than polyester, making it ideal for delicate prints. It's also essential to choose a printing method that matches the fabric's characteristics, such as screen printing for thicker materials or heat transfer for lighter ones.

Printing Techniques: Printing techniques include digital printing, inkjet printing, and sublimation printing. Digital printing uses a printer to apply ink directly onto the fabric, while inkjet printing uses dots of ink to create detailed designs. Sublimation printing involves using heat to fuse the ink onto the fabric. The choice of technique depends on the level of detail needed in the final product.

Once the printing process is complete, the next step is to prepare the fabric for cutting. This involves removing the backing layer if necessary and preparing the surface for stitching or ironing. It's important to ensure that the fabric is evenly coated with ink to avoid uneven cuts during the cutting process.

Cutting Techniques: There are several methods for cutting printed textiles, each with its advantages and limitations.

-

Straight Line Cutting:

- Advantages: Quick and easy, requiring minimal skill.

- Disadvantages: Can leave unfinished edges or produce a jagged cut.

- Example: A company may use this technique for quick production runs of uniformly printed items.

-

Edge Cutting:

- Advantages: Preserves the integrity of the design, creating a clean, professional look.

- Disadvantages: More time-consuming and requires more skill.

- Example: A fashion brand might use edge cutting for custom-designed garments to maintain consistent aesthetics.

-

Pattern Cutting (Square Cut):

- Advantages: Provides a consistent finish and can be used with various printing methods.

- Disadvantages: May require multiple passes to achieve optimal results.

- Example: A home decor company might use this technique for wallpapers with intricate patterns.

-

Folded Cutting:

- Advantages: Allows for a variety of finishes without compromising on quality.

- Disadvantages: Can result in wasteful cuts and requires more planning.

- Example: A clothing manufacturer might use folded cutting for shirts that feature decorative folds or pockets.

Considerations: When cutting printed textiles, there are several factors to keep in mind:

- Fabric Type: Different fabrics have varying levels of stretch and elasticity, impacting how they will stretch and recover after cutting.

- Design Specifications: Clear communication about design details is crucial to avoid misinterpretation and inadvertent errors during the cutting process.

- Quality Control: Checking the accuracy of the cut is critical to prevent defects in finished products. This includes measuring the length and width of the cut accurately, as well as checking for any imperfections.

- Waste Management: Minimizing waste by carefully planning the layout of the fabric before cutting can help save resources and reduce costs.

Conclusion: The ability to cut printed textiles effectively is a skill that requires both technical knowledge and practical experience. By following the tips and considerations outlined above, businesses can produce high-quality printed textiles that meet consumer demands and exceed customer expectations. Whether it's for fashion, home decor, or other industries, effective cutting techniques are key to delivering exceptional products that stand out in a crowded marketplace.

I: Introduction

今天我们来聊聊纺织品打印后的裁切问题,在纺织品制作过程中,打印技术为我们提供了无限的创意和可能性,但如何正确地裁切这些材料,确保最终的成品既美观又实用,是每个从业者都需要掌握的技能。

II: 纺织品打印的基本知识

A: 纺织品打印的定义和原理

纺织品打印是一种通过数字技术将图案或纹理直接复制到织物上的过程,它通常使用特殊的打印机和材料,能够快速、准确地生成高质量的图案。

B: 打印材料的准备与选择

在裁切纺织品之前,需要确保打印材料的质量和适用性,选择合适的材料可以确保打印效果清晰、持久,同时避免因材料问题导致的裁切困难或损坏。

C: 打印材料的裁切技巧

- 使用专业的裁切工具和设备:专业的裁切工具和设备可以确保裁切的精确度和效率,在选择裁切工具时,需要考虑其材质、精度、耐用性等因素。

- 使用表格或模板进行裁切:使用预先准备好的表格或模板可以大大提高裁切的效率和准确性,在裁切之前,需要仔细阅读打印图案,确保其尺寸和形状与所需的成品相匹配。

III: 案例说明:纺织品打印裁切的实际操作

A: 案例一:纺织品打印后如何裁切

假设我们有一件由丝绸制成的衣物,其图案是通过纺织品打印技术制作的,在裁切之前,我们需要先仔细阅读打印图案,确定其尺寸和形状,使用专业的裁切工具和设备进行裁切,在裁切过程中,需要注意保持稳定的操作姿势,避免因操作不当导致的损坏或误差,使用熨斗或其他工具进行最后的整理和修整,确保成品既美观又实用。

B: 案例二:纺织品打印裁切的实际操作中的注意事项

在实际操作中,还需要注意以下几点:要确保使用的裁切工具和设备是经过专业培训和认证的;要仔细阅读打印图案,确保其尺寸和形状与成品相匹配;在裁切过程中要保持稳定的操作姿势和心态,避免因操作不当导致的误差或损坏。

IV: 注意事项与建议

A: 注意事项

在进行纺织品打印裁切时,需要注意以下几点:要选择合适的打印材料和工具;要仔细阅读打印图案,确保其尺寸和形状与成品相匹配;要保持稳定的操作姿势和心态,避免因操作不当导致的误差或损坏,还需要注意保持工作环境的整洁和卫生。

B: 建议

为了确保纺织品打印裁切的质量和效率,可以采取以下建议:要选择专业的裁切工具和设备;要使用预先准备好的表格或模板进行裁切;要遵循正确的操作步骤和方法,确保裁切的准确性和效率,还需要注意保持工作环境的整洁和卫生,避免因环境因素导致的误差或损坏。

V: 总结与展望

纺织品打印后的裁切是纺织品制作过程中的重要环节,需要掌握正确的技巧和方法,通过本文的介绍和实践案例说明,我们可以了解到纺织品打印裁切的注意事项和操作技巧,随着纺织品的不断发展和创新,我们还需要不断学习和掌握新的技术和方法,提高纺织品制作的效率和品质。

Articles related to the knowledge points of this article:

Understanding the World of Textile Ingredients and Components

Custom Textile Dryers for Enhanced Performance and Cost-Effectiveness

The Unique Scent of山西个性化针纺织品批发价格

Exploring the World of Fashionable Textiles with Xin Yue Textiles Live Show