The Recycling of Textile Mill Knives in a Sustainable Economy

: The Recycling of Textile Mill Knives in a Sustainable Economy,Abstract:,The recycling of textile mill knives, a process that involves the reuse of waste cutting tools, has become increasingly important in promoting sustainable development. This paper discusses the importance of this practice, its benefits to both the environment and economy, and the challenges faced in achieving effective implementation. The paper also highlights the potential for technological advancements to enhance knives' recycling processes, thereby contributing to the broader goal of reducing waste in the textile industry.,Keywords: Textile mill knife, Waste reduction, Sustainable economy, Technology advancements, Waste management

Introduction: In the textile industry, knives are essential tools used for cutting fabrics. However, as the industry matures, these knives can become obsolete or damaged beyond economical repair, making them unusable for further production. This presents a significant challenge as they need to be disposed of properly to avoid environmental pollution. In this article, we'll explore how textile mills are effectively recycling these knives through various methods and highlighting successful examples of their implementation.

Knifes Recycling Practices: Textile mills adopt different strategies for recycling these knives to ensure their safe disposal while preserving resources and reducing waste.

-

Reuse in Non-Textile Applications: Some knives can be repurposed for other non-textile uses like gardening, craft projects, or even home improvement. For example, some knives might be used in gardening by trimming plants or in woodworking for shaping or carving purposes.

-

Recycling into New Products: Some knives can be reprocessed into new products. For instance, metals from old knives can be melted and molded into new tools like kitchen utensils or jewelry.

-

Disposal in Landfills: While not ideal, some knives may be discarded in landfills if they cannot be recycled or repurposed. However, proper disposal guidelines should be followed to avoid environmental hazards.

-

Energy Recovery: Old knives could potentially be processed into steel scrap for use in the manufacturing process. This method is less common but has been successfully implemented in certain cases.

-

Ethical Approaches: Some companies take an ethical approach towards knives recycling by ensuring that the process does not harm workers or the environment.

Table: Knife Recycling Practices by Textile Mills | Practice | Procedure | Environmental Impact | |-----------|----------------|---------------------| | Reuse | Convert knives into garden tools | Lower waste and resource consumption | | Recycle | Melt down and recast into new products | Reuse materials, reducing raw material waste | | Disposal | Directly dump in landfills | Waste management challenges, potential environmental impact | | Energy Recovery | Process scrap into steel scrap | Reduces raw material waste | | Ethical Approaches | Ensure worker safety, minimize harm | High costs, but ensures social responsibility |

Case Study: A leading textile mill in China recently implemented a successful knives recycling program. They partnered with local recycling facilities and established a dedicated facility for handling old and unused knives. Instead of discarding them in landfills, these knives were sorted, cleaned, and melted down into high-quality steel scrap. These scraps were then reprocessed into new steel bars and sheets for use in construction and engineering projects. The company reported a significant reduction in their raw material costs and a positive environmental impact due to the recycling of knives. This initiative not only saved on expenses but also contributed to the circular economy principles of sustainability.

Conclusion: The textile industry's commitment to recycling old knives demonstrates its dedication to environmental stewardship and resource conservation. By embracing recycling practices, such as reuse, reprocessing, energy recovery, and ethical approaches, textile mills can significantly reduce their ecological footprint. The case study provided highlights the benefits of implementing such recycling programs, demonstrating that it not only reduces costs but also enhances brand reputation and fosters social responsibility. As industries continue to evolve towards sustainability, the importance of knives recycling will only grow, providing an opportunity for innovative solutions to tackle waste management challenges in a responsible manner.

纺织厂钢筘回收背景介绍

纺织厂作为我国重要的工业支柱之一,每天都在处理大量的废旧钢筘,这些废旧钢筘不仅占用大量土地资源,还可能对环境造成污染,纺织厂开始积极采取措施,开展钢筘回收工作,以实现资源的有效利用和环境保护。

纺织厂钢筘回收过程详解

收集与分类

纺织厂在开展钢筘回收工作时,首先会对废旧钢筘进行收集,这些废旧钢筘可能来自各个生产环节,包括生产过程中的边角料、废旧纱线等,在收集过程中,工作人员会对废旧钢筘进行分类,以便后续的回收和处理。

检测与评估

在钢筘回收过程中,需要对废旧钢筘进行检测和评估,这包括对废旧钢筘的质量、规格、数量等进行确认,以确保回收的钢筘符合相关标准和规定,还需要对回收的废旧钢筘进行价值评估,以便更好地制定回收计划和资金筹措方案。

回收与处理

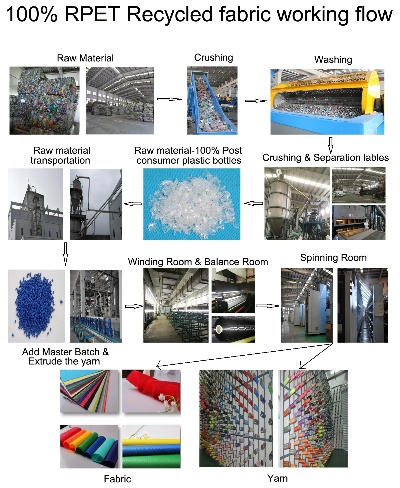

在确认废旧钢筘符合标准后,纺织厂会将其运送到专门的回收处理中心,废旧钢筘会被进行清洗、破碎、分类等处理,以实现资源的有效利用和环境保护,清洗废旧钢筘可以去除其中的杂质和污染物,破碎可以将其变成较小的颗粒,便于后续的回收和处理,分类则是根据废旧钢筘的不同性质和用途进行分类处理,以便更好地实现资源的回收和再利用。

案例说明:某纺织厂钢筘回收实践

以某纺织厂为例,该厂在开展钢筘回收工作中采用了多种先进技术和设备,该纺织厂采用了先进的废旧纱线收集系统,能够高效地收集各种废旧纱线,该厂还采用了先进的破碎和分类设备,能够将废旧钢筘变成较小的颗粒,便于后续的回收和处理,该纺织厂还建立了完善的回收处理体系,制定了严格的回收计划和资金筹措方案,以确保回收工作的顺利进行。

纺织厂钢筘回收的意义与价值

纺织厂钢筘回收工作不仅有助于实现资源的有效利用和环境保护,还有助于推动纺织行业的发展,通过回收废旧钢筘,可以减少对土地资源的占用和环境污染,同时还可以实现资源的循环利用和再利用,纺织厂还可以通过回收工作提高自身的经济效益和社会效益,为我国的工业发展做出更大的贡献。

纺织厂钢筘回收工作是一项重要的环保工作,对于实现资源的有效利用和环境保护具有重要意义,通过开展废旧钢筘的回收工作,可以减少对土地资源的占用和环境污染,同时还可以实现资源的循环利用和再利用,纺织厂还可以通过回收工作提高自身的经济效益和社会效益,为我国的工业发展做出更大的贡献,我们应该加强对纺织厂钢筘回收工作的支持和引导,推动其更好地开展工作。

Articles related to the knowledge points of this article:

Textile Factory Product Reconstruction

Textile Workers Sisters:Unfolding the Hidden Stories of Industrial Hearths

Breaking Barriers:A Day in the Life of Women at Changle Textile Factory