Renewing Pathways in the Textile Industry

In today's fast-paced world, textile industries are constantly seeking innovative ways to enhance their production processes. One such approach is the implementation of renewable pathways in the industry. This involves using renewable energy sources like solar or wind power to power factories and reduce dependence on fossil fuels. By doing so, the textile sector can not only reduce its carbon footprint but also improve efficiency and sustainability. Additionally, adopting renewable pathways can lead to cost savings by reducing electricity bills and maintenance costs associated with traditional energy sources. Ultimately, this shift towards sustainability will not only benefit the environment but also drive economic growth and innovation within the textile industry.

Introduction: In today's globalized market, the textile industry is facing numerous challenges that demand innovation and adaptation. As we delve into the realm of 'Renewing Pathways in the Textile Industry', we will explore how this sector is adapting to new technological advancements, shifting consumer preferences, and addressing environmental concerns. Through case studies and data analysis, we aim to highlight the importance of redefining the traditional pathways within this dynamic industry, ensuring sustainability and growth for years to come.

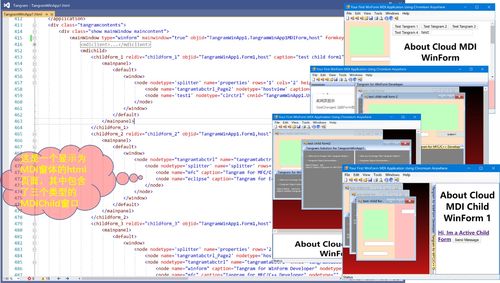

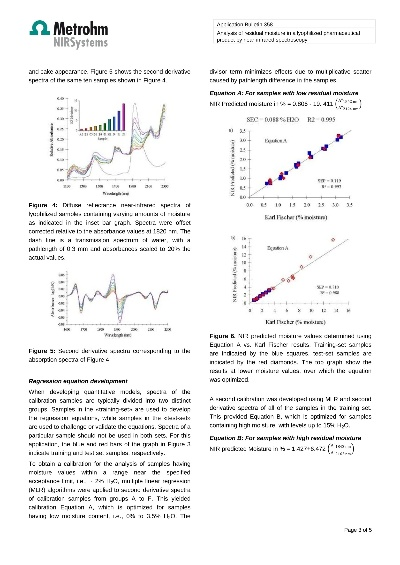

I. Technological Progress: The Future of Textile Innovation The textile industry has witnessed a significant shift towards digitalization and automation over the years. With the advent of advanced technology, companies are now able to produce high-quality fabrics with greater precision and efficiency. For example, machine learning algorithms can be used to optimize production processes, reducing waste and minimizing costs. In addition, robotic weaving systems have revolutionized the textile industry by enabling manufacturers to produce complex patterns on large scales.

Table: Comparison of Pre-Technology and Post-Technology Textile Production

| Category | Pre-Technology | Post-Technology |

|---|---|---|

| Production Efficiency | Low | High |

| Waste Reduction | High | Significantly reduced |

| Product Variety | Limited | Extensive |

| Cost | High | Modest |

II. Shifting Consumer Preferences: Embracing Sustainability As consumers become increasingly aware of their impact on the environment, they are demanding more sustainable options from the textile industry. Companies must respond by adopting eco-friendly practices, such as using renewable energy sources in manufacturing, reducing water usage, and producing materials with biodegradable properties. One example of a successful company that has embraced these practices is Martha Stewart, who has launched a line of organic clothing made from recycled polyester and hemp fibers.

III. Environmental Concerns: Reducing Emissions The textile industry is not immune to environmental issues, including air and water pollution, which can have severe health implications. To combat these problems, companies are investing in cleaner technologies, such as low-emitting dyes and water-saving techniques. Moreover, many manufacturers are adopting circular economy models, which focus on reducing waste and maximizing the value of their resources. This model has been implemented by the Italian company Uniqlo, which has successfully transitioned from traditional production methods to a more sustainable approach that reduces its carbon footprint while maintaining customer satisfaction.

IV. Case Study: Transforming Textile Manufacture To illustrate the practical application of these strategies, let us take a closer look at the journey of Renewing Pathways in the Textile Industry. Founded in 2010, this company was originally an importer of textile machinery and accessories. However, as it became clear that traditional methods were no longer sustainable, the company began exploring alternative approaches.

By 2015, Renewing Pathways had developed an automated system that could produce high-quality garments with minimal waste. The company also introduced eco-friendly packaging materials that were biodegradable and recyclable. In 2018, the company launched a line of organic cotton clothing made from post-consumer materials. These initiatives not only increased customer satisfaction but also attracted more eco-conscious consumers who were looking for sustainable alternatives.

Conclusion: Renewing Pathways in the Textile Industry is a testament to the resilience of our planet. By embracing technological advancements, shifting consumer preferences towards sustainability, and addressing environmental concerns, companies can thrive in a constantly changing landscape. The story of Renewing Pathways serves as a reminder that by adapting and innovating, we can create a brighter future for the textile industry and for our world. Let us all strive to follow in their footsteps, creating paths that are both economically viable and environmentally conscious.

公司简介

重道纺织品有限公司是一家专注于纺织品研发、生产和销售的企业,公司秉承着“品质至上,创新驱动”的理念,致力于为客户提供高质量、高性价比的纺织品产品,在过去的几年里,公司凭借其卓越的产品质量和不断创新的精神,在国内外市场上取得了显著的成绩。

产品与服务

-

产品种类丰富:重道纺织品有限公司的产品涵盖了各种类型的纺织品,包括但不限于床上用品、家居装饰品、服装配件等,公司注重产品的研发和创新,不断推出新的产品款式和功能,以满足客户的不同需求。

-

质量保证:公司一直秉承着严格的质量控制标准,从原材料采购到生产过程控制,再到成品检验,每一个环节都严格把关,确保产品质量,公司还建立了完善的售后服务体系,为客户提供优质的售后服务。

-

案例展示:为了更好地说明重道纺织品有限公司的产品与服务,我们以一个具体的案例进行说明,某客户在购买重道纺织品有限公司的床上用品后,对其舒适度和耐用性表示满意,该公司还提供定制服务,可以根据客户的需求进行个性化定制,满足不同客户群体的需求。

品质与创新

-

品质保障:重道纺织品有限公司在品质保障方面采取了多项措施,公司建立了严格的质量控制体系,从原材料采购到生产过程控制,再到成品检验,每个环节都由专业人员进行把关,公司还注重产品的环保和可持续性,采用环保材料和工艺,确保产品的环保性和可持续性,公司还注重产品的售后服务,为客户提供优质的售后服务和解决方案。

-

创新驱动:在创新方面,重道纺织品有限公司注重研发和创新,公司拥有一支专业的研发团队,不断推出新的产品款式和功能,以满足客户的不同需求,公司还积极引进先进的生产技术和设备,提高生产效率和产品质量,公司还注重产品的差异化竞争,不断推出具有独特性和竞争力的产品。

-

未来发展方向:在未来发展中,重道纺织品有限公司将继续秉承“品质至上,创新驱动”的理念,加强产品研发和创新力度,提高产品质量和竞争力,公司还将加强品牌建设和市场营销,提高品牌知名度和美誉度,公司还将拓展国内外市场,提高市场份额和销售业绩。

-

案例分析:以某客户为例,该客户在购买重道纺织品有限公司的产品后表示非常满意,该客户表示该产品不仅舒适度高、耐用性强,而且具有很好的环保性和可持续性,这表明重道纺织品有限公司的产品在品质和创新方面都得到了客户的认可和好评。

重道纺织品有限公司是一家专注于纺织品研发、生产和销售的企业,公司在品质与创新方面都取得了显著的成绩,公司将继续加强产品研发和创新力度,提高产品质量和竞争力,拓展国内外市场,为更多的客户提供优质的产品和服务,公司还将注重品牌建设和市场营销,提高品牌知名度和美誉度。

Articles related to the knowledge points of this article:

Summary of Textile Product Photography Work Contents

The Rise of National Textile A-Class:An Introduction to the

Exploring the Market for Sustainable Textile Recycling in Fuzhou