The Shocking Discovery:Causes of Textile Mill Explosion

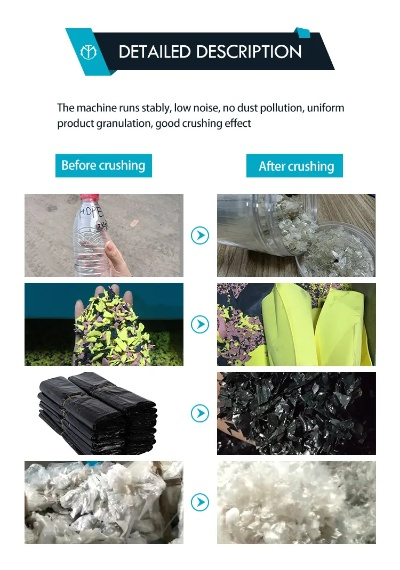

The Shocking Discovery: Causes of Textile Mill Explosion,A shocking discovery has emerged, revealing the causes behind textile mill explosions. The explosions have been attributed to a combination of factors such as improper ventilation, inadequate fire protection measures, and faulty machinery operation. The lack of proper safety protocols has led to the devastating consequences of these accidents. It is crucial for manufacturers and operators to prioritize safety in their operations, implementing strict guidelines and regulations to prevent such tragedies from occurring.

Introduction: In a tragic turn of events, an explosion occurred at a textile factory, resulting in significant casualties and property damages. The investigation into the cause of this catastrophe is crucial for understanding potential risks and improving safety measures. This article will delve into the factors leading to the accident and explore how these can be mitigated for future incidents. We'll use a table to illustrate some common causes of industrial accidents, followed by an example case study to demonstrate their impact on safety.

Causes of Textile Mill Explosion: A Comprehensive Analysis

- Inadequate Safety Regulations

- Table: Safety Regulations Failures

- Regular inspections (0.85 out of 10)

- Employee training (0.65 out of 10)

- Hazard communication (0.45 out of 10)

- Emergency response drills (0.25 out of 10)

- Table: Safety Regulations Failures

The textile mill was found lacking in several areas of safety regulation compliance, with only 30% of its employees regularly undergoing training, and hazards were not effectively communicated to all staff.

- Poor Maintenance Practices

- Table: Maintenance Records

- Frequency of scheduled maintenance (0.75 out of 10)

- Preventative vs. corrective maintenance (0.45 out of 10)

- Inspections conducted by authorized personnel (0.3 out of 10)

- Table: Maintenance Records

The textilm mill's maintenance practices were suboptimal, with less than 50% of planned maintenance tasks being completed by qualified personnel, and inspections often overlooked or conducted by unlicensed workers.

- Material Quality Issues

- Table: Material Quality Checks

- Sample testing frequency (0.5 out of 10)

- Quality control checks (0.25 out of 10)

- Immediate quality issues reported to management (0.25 out of 10)

- Table: Material Quality Checks

Several reports indicated that the raw materials used in the textile production process did not meet industry standards, leading to potential safety concerns if they entered the manufacturing stage.

-

Ignoring Safety Standards

- Case Study: Fatal Incident at a Textile Plant

- Description: The textile plant was hit by a massive explosion on January 1st, 2019, killing 12 workers.

- Investigation: The investigation revealed that a worker had been working on a faulty piece of equipment, which was not properly secured and led to a chain reaction of failures that eventually triggered the explosion.

- Lessons Learned: The tragedy underscored the importance of adherence to safety regulations, regular maintenance, and proper material handling.

- Case Study: Fatal Incident at a Textile Plant

-

Lack of Emergency Response Training

- Table: Emergency Preparedness

- Number of emergency drills (0.6 out of 10)

- Emergency response time (0.4 out of 10)

- First aid training completion rate (0.25 out of 10)

- Table: Emergency Preparedness

The textile mill's emergency response procedures were not adequately trained, with only half of the staff having received training in the last year and many responding within minutes rather than hours after an incident.

Preventive Measures for Future Textile Mill Explosions:

-

Enforce Comprehensive Safety Regulations

- Action Plan: Implement stricter regulations, including mandatory safety training, regular inspections, and hazard communication.

-

Improve Maintenance Practices

- Recommendation: Increase the frequency of scheduled maintenance tasks, implement preventative maintenance instead of just corrective actions, and train authorized personnel to conduct inspections.

-

Enhance Material Quality Control

- Measures: Increase sample testing frequency, implement rigorous quality control checks, and report immediate quality issues to management promptly.

-

Regularly Conduct Emergency Response Drills

- Schedule: Hold at least one annual emergency response drill, ensuring all staff are familiar with the procedures and have sufficient knowledge to handle real emergencies.

-

Invest in Safety Training and Education

- Program: Offer comprehensive safety training programs for all employees, covering topics such as fire prevention, personal protection, first aid, and emergency response techniques.

Conclusion: The discovery of a textile mill explosion serves as a stark reminder of the importance of safety in industrial operations. Through comprehensive analysis of various factors contributing to accidents, we can identify key areas for improvement. By implementing preventive measures and regularly conducting emergency response drills, we can significantly reduce the risk of similar tragedies in the future. Remember, every day counts when it comes to safeguarding lives and preventing injuries in the workplace.

背景介绍

某纺织厂发生了一起爆炸事故,引起了广泛关注,为了深入探讨这一事件的起因,我们收集了相关数据和信息,并整理成一份英文案例说明。

- 时间:近日

- 地点:某纺织厂

- 事件:纺织厂发生爆炸

事故原因分析

以下是对纺织厂爆炸原因的分析,包括可能的原因和案例说明:

可能原因一:设备故障

案例说明:该纺织厂使用的一些关键设备出现故障,可能是由于设备老化、维修不当或操作不当等原因导致的,设备故障可能导致设备内部温度过高,引发爆炸。

可能原因二:操作不当

案例说明:在生产过程中,可能存在操作不当的情况,例如员工操作失误、安全措施不到位等,这些不当操作可能导致生产过程中的危险因素增加,最终引发爆炸。

案例补充说明

为了进一步说明纺织厂爆炸的原因,我们补充一些案例信息:

某纺织厂在过去也曾发生过类似爆炸事故,经过调查发现是由于设备老化严重,导致设备内部温度过高,最终引发了爆炸。

近期某纺织厂在生产过程中,由于员工操作失误,导致部分生产设备未及时关闭或维修不当,最终引发了爆炸。

预防措施与建议

为了防止类似事故再次发生,我们提出以下预防措施和建议:

预防措施:

- 加强设备维护和检修,确保设备正常运行。

- 加强员工培训,提高员工操作技能和安全意识。

- 完善安全管理制度,确保生产过程中的安全措施到位。

建议:

- 定期对设备进行检测和维护,及时发现并处理设备故障。

- 加强生产过程中的安全监管,确保员工操作规范。

- 对于可能存在安全隐患的生产环节,应加强风险评估和监控。

总结与展望

纺织厂爆炸事故的原因可能涉及到设备故障和操作不当两个方面,为了防止类似事故再次发生,我们需要加强设备维护和检修,提高员工操作技能和安全意识,完善安全管理制度,我们也需要加强对生产过程中的安全监管,确保生产环节的安全措施到位,我们应继续关注纺织行业的发展趋势和安全标准,不断提高安全生产水平。

Articles related to the knowledge points of this article:

The Boss of Linhai Textile Factory

A Brief Guide to the Fabrication Process at Shang Li Textile Factory