The 2023 Challenges in the Cross-Strait Textile Industry

The textile industry has always been a vital part of China's economy, providing employment opportunities for millions and contributing significantly to the global market. In recent years, however, the industry has faced unprecedented challenges as a result of factors such as increased competition from overseas markets, shifting consumer demands, and rising raw material costs. To navigate these challenges successfully, cross-strait enterprises must adopt innovative strategies and adapt their operations accordingly. This article will explore some of the key challenges facing the textile industry in 2023 and provide insights on how to overcome them.

Competitive Exposure: A Tale of Two Planets

In recent years, as Chinese textile companies have expanded into more mature markets like Europe and North America, they have encountered stiff competition from established players in those regions. For instance, according to the International Textile Council (ITC), the number of new textile mills across China has risen to 58 since 2019, which has led to intense market scrutiny and price competition among domestic producers. As a result, many small and medium-sized enterprises (SMEs) are struggling to survive due to the lack of resources and expertise needed to compete on an equal footing with large multinational corporations.

To combat this competitive exposure, cross-strait enterprises need to focus on improving their product quality and innovation capabilities. They should invest in research and development to develop new designs and technologies that meet the unique demands of different markets. Additionally, adopting cost-effective production methods and streamlining supply chains can help reduce operational expenses and increase efficiency. By doing so, companies can enhance their competitiveness in both domestic and international markets.

Consumer Changes: The Need for Sustainable Products

In the past decade, consumers' attitudes towards sustainability have shifted significantly, favoring products that are environmentally friendly and socially responsible. This trend is particularly evident in China, where consumers are becoming more conscious about the impact their purchasing decisions have on the environment and society. As a result, cross-strait manufacturers must reevaluate their production methods to align with these changes.

One strategy is to incorporate eco-friendly materials such as bamboo or recycled polyester into their production processes. By doing so, they can reduce their carbon footprint and demonstrate their commitment to sustainability to their customers. Additionally, companies can also explore alternative packaging solutions that use biodegradable materials or promote recycling programs within their supply chain. These actions will not only appeal to environmentally conscious consumers but also enhance the brand image of cross-strait companies as leaders in sustainable practices.

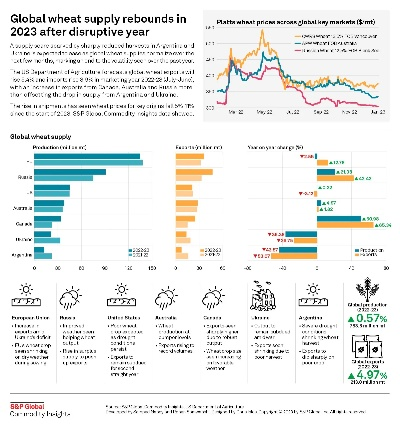

Raw Material Prices: A Cost Pressure

One of the most significant challenges facing cross-strait textile industries in 2023 is the increasing cost of raw materials, particularly cotton and synthetic fibers. Due to factors such as weather conditions, labor shortages, and geopolitical tensions, prices for these commodities have surged over the past few years. As a result, manufacturers are forced to increase their prices or cut back on production to maintain profitability.

To cope with this challenge, cross-strait companies must adopt cost-effective production techniques such as automation and lean manufacturing. By optimizing their processes and reducing waste, they can lower their operating costs while still producing high-quality products. Additionally, exploring alternative raw materials such as recycled plastic or agricultural waste can help mitigate some of the pressures associated with rising raw material costs. By taking these measures, companies can remain competitive in the long run while addressing short-term financial constraints.

Technological Advancements: The Future of Textile Production

As technology continues to advance at an unprecedented pace, cross-strait textile industries are witnessing a shift towards digitalization and automation. Machine learning, artificial intelligence (AI), and robotics are transforming the way textile production is done, making it faster, more efficient, and cost-effective.

For example, AI-powered machine vision systems can be used to inspect fabrics for defects in real time, saving time and reducing errors. Similarly, robotic weaving machines can handle complex patterns and designs with precision and speed. These technological advancements have already begun to transform cross-strait textile industries, offering new opportunities for growth and innovation.

However, integrating these technologies requires significant investment in research and development as well as workforce training. Therefore, cross-strait companies must prioritize their R&D efforts to develop new technologies and stay ahead of the curve. Additionally, they should consider investing in human capital by creating training programs to ensure their workers can effectively operate these new tools and equipment.

Emerging Markets: The Potential of New Demand

As economies around the world continue to grow and middle class populations expand, cross-strait textile industries face the prospect of new market opportunities in emerging markets. Countries like Vietnam, Indonesia, and Brazil are rapidly developing their textile industries and are becoming major players on the global stage.

Cross-strait companies that can tap into these emerging markets can gain significant growth opportunities by focusing on localized demand and tailoring their products to meet specific cultural preferences and economic conditions. For example, they could offer locally produced products that cater to the tastes of the local population while also promoting their own brands through marketing efforts in other countries.

Additionally, cross-strait companies can also benefit from collaborations with local suppliers and manufacturers in emerging markets who can provide them with low-cost labor and specialized skills needed for certain production processes. These partnerships can help companies expand their reach beyond traditional markets while also fostering mutual growth between the two sides.

Regulatory Challenges: The Importance of Compliance

As cross-strait textile industries expand globally, they are increasingly subject to regulatory requirements imposed by governments worldwide. These regulations often cover aspects such as labor laws, environmental standards, and anti-monopoly policies. Companies that fail to comply with these regulations may face fines, penalties, or even legal action from authorities.

Therefore, cross-strait manufacturers need to pay close attention to regulatory changes in various jurisdictions around the world. They should work closely with legal advisors and consultants to ensure compliance with all relevant regulations and best practices for sustainable production. Additionally, adopting standardized operating procedures and implementing effective internal controls can help companies minimize risk and ensure they remain compliant with changing regulatory landscapes.

Global Supply Chain Strategies: Building Trust in Collaboration

In order to thrive in today's globalized economy, cross-strait textile companies must adopt effective global supply chain management strategies that build trust and cooperation between partners. One approach is to implement a collaborative model that emphasizes transparency, communication, and shared responsibility.

Companies can establish clear communication channels with their suppliers and partners in each country where they operate. This helps ensure that all parties understand their roles and responsibilities in achieving common goals. Additionally, companies can regularly hold joint meetings or workshops to discuss issues related to production, delivery, and quality.

Furthermore, cross-strait companies can also invest in establishing relationships with local communities and non-governmental organizations to support sustainable development projects in the region. This not only benefits the local community but also strengthens the company's reputation as a responsible corporate citizen.

Summary

In conclusion, the textile industry in China faces a myriad of challenges in 2023, including competitive exposure, shifting consumer demands, rising raw material costs, technological advancements, emerging markets, regulatory requirements, and global supply chain management strategies. However, with strategic planning and proactive adaptation, cross-strait textile companies can overcome these challenges and continue to thrive in the ever-changing global market.

海峡纺织厂概述

海峡纺织厂自创立以来,一直致力于生产高质量、环保、可持续的纺织品,在2023年,该厂凭借其创新技术、优质产品和卓越管理,在国内外市场上取得了显著的成绩。

工厂发展历程

-

早期阶段(历史背景): 在过去的几年里,海峡纺织厂经历了快速的发展阶段,他们充分利用先进的纺织技术,优化生产流程,提高产品质量,他们注重环保和可持续发展,努力减少对环境的影响。

-

近年来的发展(具体成就):

(1)技术创新:该厂不断引进先进的纺织技术,提高生产效率,他们引入了自动化生产线和智能控制系统,大大提高了生产速度和产品质量。

(2)产品升级:为了满足市场需求,该厂不断推出新产品,提高产品的附加值,他们注重产品的设计和品质,注重产品的个性化定制,满足不同客户的需求。

(3)市场拓展:该厂积极开拓国内外市场,不断扩大市场份额,他们通过参加国内外展览会、建立销售网络等方式,提高品牌知名度和市场占有率。

工厂运营案例分析

为了更好地说明工厂运营情况,我们以一个具体的英文案例为例进行分析。

环保生产与可持续发展

在某次国际纺织博览会上,海峡纺织厂展示了他们的环保生产与可持续发展理念,他们采用了先进的环保技术和设备,如循环利用材料、节能减排等,确保生产过程中的环保和可持续发展,他们注重员工的培训和教育,提高员工的环保意识和生产技能,通过这些措施,该厂不仅提高了生产效率和质量,还赢得了国内外客户的信任和好评。

工厂未来展望

展望未来,海峡纺织厂将继续秉承创新、质量、环保、可持续的理念,不断提高生产效率和质量,扩大市场份额,他们将继续引进先进的纺织技术和管理经验,优化生产流程,提高产品质量和附加值,他们还将加强与国内外客户的合作,提高品牌知名度和市场占有率,他们还将注重员工的培训和教育,提高员工的综合素质和创新能力。

海峡纺织厂在2023年取得了显著的成绩和进步,他们充分利用先进的纺织技术和管理经验,优化生产流程,提高产品质量和附加值,他们注重环保和可持续发展,努力减少对环境的影响,在未来,海峡纺织厂将继续秉承创新、质量、环保、可持续的理念,不断提高生产效率和市场份额。

Articles related to the knowledge points of this article:

The Unexpected Turn of a Typical Workplace

The Evolution of Zhejiang Oak Tree Textile Factory