The Encyclopedia of Textiles:An Overview of Advanced Textile Techniques

This article aims to provide a comprehensive overview of the latest advancements in textile technology, highlighting key techniques and innovations that are revolutionizing the industry. From sustainable materials to advanced fabrication methods, this encyclopedia delves into the cutting-edge practices used across various industries, including apparel, footwear, and home furnishings.,Emphasizing the importance of sustainability and eco-friendliness, this section covers the use of recycled or regenerated fibers, as well as advances in dyeing and finishing techniques that minimize environmental impact. Additionally, the article explores the application of nanotechnology in fabric design, creating stronger, more durable, and breathable materials with superior performance properties.,In the realm of production methods, the article discusses the latest innovations in automation and robotics, which have led to increased efficiency and reduced labor costs. The integration of digital printing technologies, such as 3D printing and UV-curing, has also been instrumental in streamlining production processes and enhancing product quality.,Overall, this encyclopedia serves as a valuable resource for anyone interested in staying informed about the latest developments in textile technology. By providing a comprehensive overview of these cutting-edge techniques, it empowers readers to make informed decisions and stay ahead in an ever-evolving industry.

Introduction: Welcome to the world of textiles—a realm where intricate designs, exceptional materials, and advanced techniques meet to create a rich and diverse array of products. In this article, we'll dive into the comprehensive collection of textile processes, from traditional methods to cutting-edge innovations. Whether you are a seasoned textile designer, a curious enthusiast, or an industry professional in need of inspiration, this guide will provide you with the knowledge and resources you need to expand your understanding and skills. Let's start by introducing some of the most popular techniques used in textile production today.

Textile Processes:

-

Dyeing and Weaving

- Dyeing is a process that involves applying colorant substances to fabrics to produce patterns or shades. It can be done using various dyes, including natural dyes, synthetic dyestuffs, and metallic dyes.

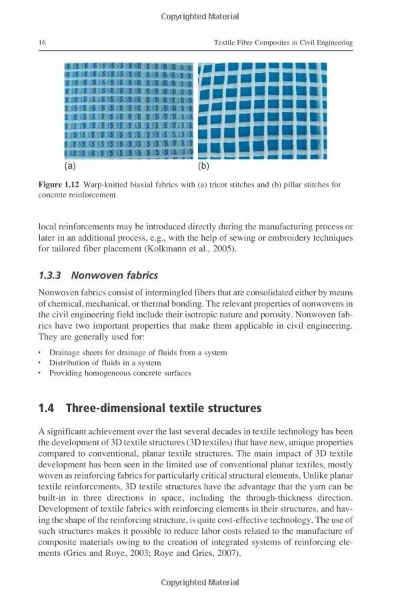

- Weaving is the process of interlacing threads onto a warp thread (the main horizontal thread) and filling them with a warp shuttle (the vertical shuttle). This creates a three-dimensional pattern on the fabric.

-

Embroidery and Knitting

- Embroidery is a technique that involves stitching tiny strands of thread to create intricate designs on a fabric. It can be applied to various types of fabrics, including cotton, silk, and even leather.

- Knitting is a method of producing yarn by interlocking loops, which are then woven into fabric. Knitting produces smooth, textured fabrics with a unique look.

-

Printing and Stitching

- Printing involves creating patterns on a piece of fabric using different printing techniques such as screen printing, pad printing, and digital printing.

- Stitching is a form of joining or connecting two pieces of fabric together using various stitches. Some common stitches include running stitch, back stitch, and cross stitch.

-

Shrinkage and Stretching

- Shrinkage refers to the reduction in size of a textile material after washing or exposure to heat. It affects the fabric's shape and appearance.

- Stretching refers to the process of increasing the width or length of a textile material. It can be done manually or through machinery.

-

Dye Sublimation and Heat Transfer Printing

- Dye sublimation is a process that involves heating a substrate to a temperature at which dye molecules sublimate (change their state from solid to gas), leaving behind a permanent print on the fabric without any solvent residues.

- Heat transfer printing is a method of applying images directly onto fabric using heat. The image is first printed on a transfer paper, which is then pressed onto the fabric and fused using heat, resulting in a permanent imprint.

-

Blending and Blending Technology

- Blending refers to the process of combining two or more distinct fibers to create new properties. It can enhance the strength, flexibility, and durability of the final product.

- Blending technology involves mixing different fibers or materials to create composite materials. This can lead to improved performance in terms of thermal stability, wear resistance, and color retention.

-

Electroweaving and Embroidery Machines

- Electroweaving is a technique that involves passing a continuous filament through an electrospinning device, which causes the filament to spin into thin threads that are then woven into a fabric.

- Embroidery machines are specialized tools used for creating intricate designs on a fabric using small embroidery hoops or needles. They offer precise control over the placement of threads and stitches.

-

Bleaching and Dyestuffs

- Bleaching is a process that involves exposing fabrics to chemicals that break down the colorfastness of dyestuffs, allowing the colors to fade or wash out.

- Dyestuffs are substances that are used to color textiles, including water-based dyes, oil-based dyes, and metallic dyes. They come in various forms, including powders, solutions, and pastes.

Example Case Studies: Case Study 1: Digital Printing on Denim A denim brand has developed a digital printing process that allows for high-quality, eco-friendly designs to be created on denim fabrics. By utilizing UV curable inks, the brand has achieved vibrant and long-lasting prints without compromising on the fabric's durability. This innovative technique has not only enhanced the aesthetic appeal of the jeans but also reduced waste by using less water and energy compared to traditional printing methods.

Case Study 2: Blending Technology in Carpet Manufacturing A carpet manufacturer has successfully implemented blending technology to create a range of luxurious flooring materials with superior performance characteristics. By combining high-end wool with recycled polyester fibers, the company has created carpets that offer both warmth and sustainability. The resulting carpets have better cushioning and durability than traditional wool carpets while still being recyclable, making them an attractive option for consumers looking for environmentally friendly flooring options.

Conclusion: The textile industry is constantly evolving, embracing new technologies and innovations to improve quality, sustainability, and consumer experience. From digital printing to blending technology, these advancements showcase how textiles can transcend boundaries and meet the demands of contemporary society. As a textile designer or industry professional, it's important to stay informed about the latest developments and embrace these techniques to create innovative and sustainable products that resonate with consumers around the world.

纺织品作为人类生活中不可或缺的组成部分,其工艺水平直接关系到产品的品质和美感,本篇纺织品工艺大全旨在为广大消费者和从业者提供全面的纺织品工艺知识,涵盖多个领域,包括基础工艺、特殊工艺、案例分析等,通过本篇内容,读者可以深入了解纺织品工艺的多样性和复杂性,掌握相关工艺技巧和要点。

基础工艺

纺织材料概述

纺织材料种类繁多,包括棉、麻、丝、毛、化纤等,每种材料都有其独特的性质和特点,适用于不同的纺织品制作,棉纤维柔软舒适,适合制作夏季衣物;丝纤维轻薄透光,适合制作高端服装面料。

纺织工艺流程

纺织工艺流程包括原料准备、织造、染整、印花、绣花等环节,织造是关键环节,包括梭织、针织等多种工艺方法,在织造过程中,需要注意控制温度、湿度、张力等参数,以确保织物的质量和性能。

特殊工艺

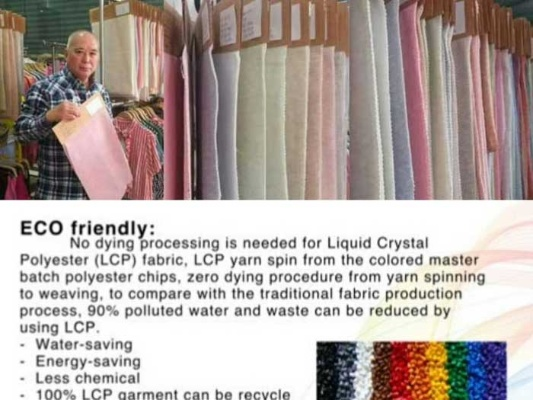

环保工艺

随着环保意识的不断提高,越来越多的纺织品开始采用环保工艺,可降解纤维、抗菌防霉纤维等特殊纤维的应用,可以有效减少环境污染,提高纺织品的使用寿命和安全性。

功能性纺织品工艺

功能性纺织品是指具有特殊功能或用途的纺织品,如防静电、抗紫外线、吸湿排汗等,在制作功能性纺织品时,需要采用相应的工艺技术,如导电纤维、热转印技术等,这些技术可以有效地提高纺织品的性能和功能。

案例分析

棉质衣物制作案例

以棉质衣物为例,介绍棉质衣物的制作流程和注意事项,在原料准备环节,需要选择高质量的棉花原料,以确保衣物的质量和性能,在织造环节,可以采用梭织或针织工艺方法,根据不同的款式和需求进行不同的选择,在染整环节,需要注意控制温度、湿度、染色剂等参数,以确保衣物的颜色和质量,在印花和绣花环节,可以根据款式和需求进行相应的工艺处理。

特殊纤维纺织品案例

以特殊纤维纺织品为例,介绍采用特殊纤维制作高端服装面料的情况,采用可降解纤维制作环保服装面料,可以有效减少环境污染;采用抗菌防霉纤维制作抗菌防霉服装面料,可以提高服装的使用寿命和安全性,在制作过程中,需要注意控制温度、湿度等参数,以及采用相应的工艺技术。

总结与展望

纺织品工艺是随着科技和时尚的发展而不断发展的,纺织品工艺将会更加注重环保、健康、时尚等方面的发展,随着人工智能、物联网等技术的不断发展,纺织品生产工艺将会更加智能化和自动化,广大消费者和从业者需要不断学习和掌握新的工艺技术和知识,以适应市场的发展和变化。

Articles related to the knowledge points of this article:

纺织品固定枪 A Comprehensive Guide to Safety and Efficiency for Industry

Top Ten Textile Brands in the Rankings:High-Resolution Images and Case Studies