The Nantong Towel Textile Plant A Gateway to Global Apparel Industry

Nantong, a city located in the Jiangsu province, China, is renowned for its textile industry and has become a global hub for apparel manufacturing. The Nantong Towel Textile Plant A stands as a beacon of this industry, offering an unparalleled opportunity to explore the complex dynamics that drive global apparel trade.,This facility is a significant player in the global market, producing a diverse range of towels, blankets, and other textile products that meet the demands of consumers across the globe. With cutting-edge technologies and a commitment to excellence in design and quality control, Nantong Towel Textile Plant A plays a critical role in the fabrication of high-quality textiles that enhance the comfort and convenience of daily life.,As a pivotal node in the apparel industry chain, the plant's success is not just about producing textiles; it's also about fostering relationships with suppliers, manufacturers, and retailers, thereby creating a strong network that contributes to the growth and sustainability of the global apparel economy.,Through its efforts, Nantong Towel Textile Plant A is positioned not only as an important producer of textiles but also as a key player in promoting international trade and collaboration within the apparel industry. Its influence extends beyond mere production, as it contributes to the global dialogue on fashion, sustainability, and the ethical sourcing of materials, shaping the future of apparel globally.

Introduction: The Nantong Towel Textile Plant, situated in the heart of Jiangsu Province in eastern China, is a testament to the enduring legacy and innovative spirit of textile manufacturing. Known for its exceptional quality and diverse product range, this factory has become a beacon of global industry, showcasing the power of local craftsmanship in the global apparel market.

Table of Contents:

- History and Evolution of Nantong Towel Textile Plant

- Current State of the Plant's Production

- Innovations in Technology and Quality Control

- Case Study: Nantong Weave

- Global Outreach and Market Profitability

- Challenges Facing the Plant Today

- Future Development Plans

- Conclusion: Nantong Towel Textile Plant as a Global Brand

History and Evolution of Nantong Towel Textile Plant: Established in the late 19th century, the Nantong Towel Textile Plant has undergone several phases of development, each one reflecting the changing needs and demands of the global apparel industry. From humble beginnings, it has grown into a leading player in the textile sector, with a reputation for excellence in fabrication and design.

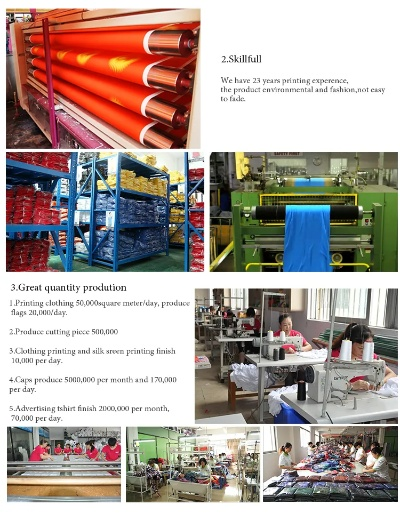

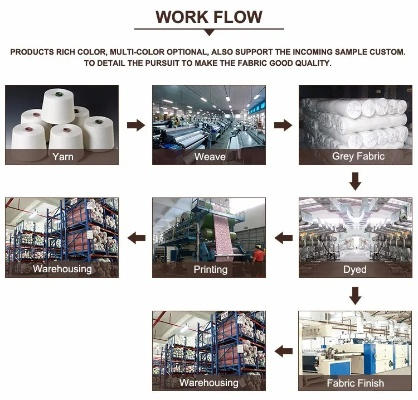

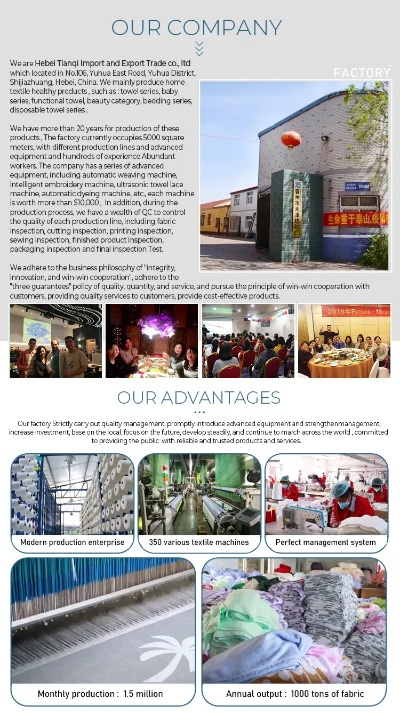

Current State of the Plant's Production: Today, the plant employs over 1,000 skilled workers, operating at a capacity of approximately 10 million square meters annually. It boasts state-of-the-art machinery, including automatic weaving machines and dyeing facilities, that ensure consistent high-quality standards in all its products. The production process involves careful selection of fibers, meticulous cutting, and precise stitching techniques, resulting in towels that are soft, absorbent, and durable.

Innovations in Technology and Quality Control: To stay ahead in the competitive global market, Nantong has continuously invested in research and development. The use of eco-friendly materials, energy-efficient dyeing processes, and automated testing methods have been integrated into its production lines. Moreover, regular training sessions and workshops provide employees with skills enhancement, ensuring that they meet the highest standards set by international quality management systems.

Case Study: Nantong Weave One notable example of innovation is Nantong Weave, a proprietary technology developed by the factory. This unique weave pattern not only adds aesthetic appeal but also enhances durability. The weave is characterized by its fine texture and strong resistance to pilling and creasing, making it an ideal choice for premium bathrobes and beach towels.

Global Outreach and Market Profitability: Nantong Towel Textile Plant's products are distributed globally through various channels, from major retailers to online platforms like Amazon and Alibaba. The factory's ability to adapt to different market conditions and cultural preferences has led to significant profitability, especially during times of economic downturns.

Challenges Facing the Plant Today: Despite its success, Nantong faces challenges such as increased competition from emerging markets and stricter environmental regulations. These factors necessitate continuous improvements in production efficiency and sustainability practices.

Future Development Plans: Looking ahead, the plant plans to further expand its global presence through partnerships with established brands and investing in new technology. It also aims to diversify its product line to include more eco-friendly and sustainable options to meet the evolving demand for green products.

Conclusion: Nantong Towel Textile Plant as a Global Brand The Nantong Towel Textile Plant stands not just as a symbol of Chinese textile excellence but also as a global brand that embodies innovation, quality, and sustainability. With its commitment to excellence and its relentless pursuit of technological advancements, this factory has carved out a niche for itself in the ever-evolving world of textile manufacturing. Its story serves as a reminder that even the most modest enterprises have the potential to make a significant impact on global markets if they embrace the opportunities presented to them with creativity, determination, and a deep understanding of their customers' needs.

南通毛巾纺织厂概述

南通,作为江苏省的重要纺织基地,拥有众多知名的纺织企业,南通毛巾纺织厂以其精湛的工艺、丰富的产品种类和良好的口碑赢得了广大消费者的信赖,该厂不仅传承了传统纺织工艺,还积极引入现代生产技术,实现了传统与现代的完美融合。

南通毛巾纺织厂的产品特点

南通毛巾纺织厂的产品以高质量、高性价比、环保可持续性为主打特点,其毛巾产品采用优质原料,经过严格的工艺流程,确保每一根毛巾都具备优良的质地和舒适的手感,该厂还注重产品的环保性,采用环保染料和工艺,确保产品的可持续性。

南通毛巾纺织厂的生产流程

- 原料采集:南通毛巾纺织厂从优质的原料供应商处采购高质量的原料,确保毛巾产品的原料质量。

- 织造工艺:采用先进的织造技术,对毛巾进行精细编织,该厂注重每个环节的质量控制,确保织造出的毛巾符合高标准的质量要求。

- 染色工艺:采用环保染料和工艺,确保毛巾的颜色鲜艳、持久,该厂注重产品的环保性,减少对环境的污染。

- 成品检验:在成品检验环节,该厂严格把关,确保每一条毛巾都符合质量标准。

南通毛巾纺织厂的案例分析

近年来,南通毛巾纺织厂在传统工艺与现代生产技术相结合方面取得了显著成果,以下是一个具体的案例说明:

高品质毛巾的生产过程

某次,南通毛巾纺织厂接到了一批高端客户的订单,为了满足客户的特殊需求,该厂采用了先进的织造技术和环保染料,确保每一条毛巾都具备高品质的特点,在生产过程中,该厂注重每个环节的质量控制,从原料采集到成品检验都严格把关,该批高品质毛巾得到了客户的高度评价和认可。

绿色生产实践

为了实现产品的环保性,南通毛巾纺织厂积极引入绿色生产技术,该厂采用了环保染料和工艺,确保产品的可持续性,该厂还注重产品的环保宣传和教育,提高员工和消费者的环保意识,通过这些实践,南通毛巾纺织厂成功树立了良好的企业形象和品牌形象。

南通毛巾纺织厂的未来展望

展望未来,南通毛巾纺织厂将继续秉承传统工艺与现代生产技术的结合理念,不断提高产品质量和竞争力,该厂还将积极探索新的生产技术和工艺,不断推出新的产品和服务,满足消费者的需求和期望,南通毛巾纺织厂还将注重企业的可持续发展,实现经济效益和社会效益的双赢。

Articles related to the knowledge points of this article:

The Textile Factory in Jiangxi:A Case Study of the Fabric Bags

The Textile Factory Uses a Humidifier to Maintain a Comfortable Work Environment

Unleashing the Power of Textile Innovations at the 2024 Textile Expo