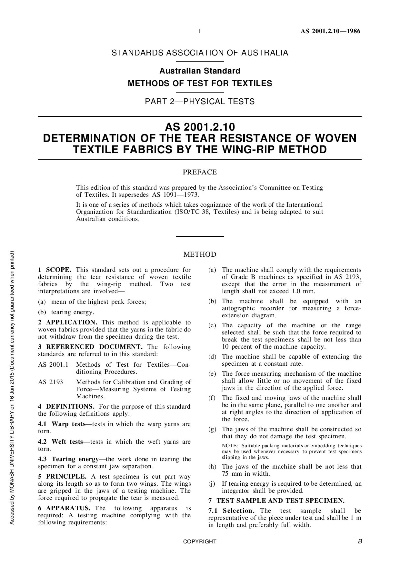

Textile Tear Proportion Testing Standards and Recommended Practices

The Tear Proportion Testing Standards are an essential part of quality control in the textile industry. This standard measures the ability of a textile material to resist tear when subjected to a forceful tensile strain. The recommended practices for tear testing include selecting appropriate test methods, ensuring accurate instrumentation and measurement, and maintaining consistent testing conditions. Additionally, it is important to understand the limitations of the tear testing method and how these limitations may affect the results. Overall, the Tear Proportion Testing Standards and Recommended Practices provide a reliable means of assessing the strength and durability of textile materials, which is critical for ensuring safe and reliable products for consumers.

Introduction to Textile Tear Testing: Textiles have an indispensable role in our daily lives. They provide comfort, style, and functionality to clothing, home décor, and even protective equipment like gloves and aprons. To ensure the integrity of these textiles, they are tested for tear resistance. This article will discuss the standards for measuring this crucial aspect of textile quality and provide some recommended practices.

Tear test standards: Tear strength tests are used to evaluate the resistance of textile materials to tears when subjected to controlled forces. These tests are essential for determining how durable and wear-resistant fabrics can be. The American Society for Testing and Materials (ASTM) has published several standard methods for assessing this property, including ASTM D638, ASTM D1925, and ASTM D412-07. These methods cover different levels of test conditions, from low force to high force applications, and include both static and dynamic tests.

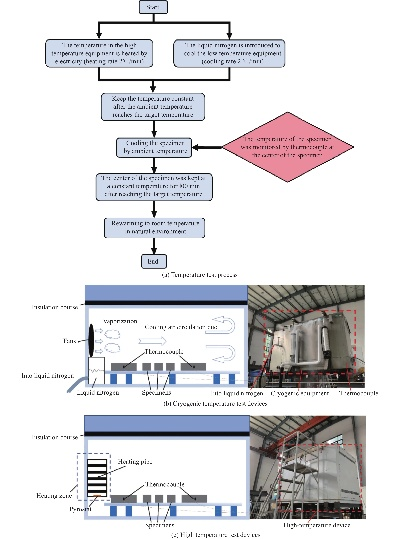

A typical tear strength test setup might look something like this:

| Test Type | Description | Apparatus |

|---|---|---|

| ASTM D638 | Low-force tear test | Tensile machine with controlled speed |

| ASTM D1925 | Dynamic tear test | Sliding pin apparatus with controlled speed |

| ASTM D412-07 | High-force tear test | Tensile tester with high tension |

Recommended Practices: To properly execute a tear test, it is essential to follow these recommendations:

-

Pre-testing: Before conducting any tear tests, the sample should be conditioned under standardized conditions. This ensures that the sample is at its equilibrium moisture content and that there are no thermal or environmental factors affecting its performance.

-

Sample Preparation: Clean, dry, and cut samples according to the required size for testing. Ensure that samples are not creased or compressed before testing.

-

Equipment Calibration: Before each test session, calibrate all equipment to ensure consistent results. Check the tension on the tensile machine, the alignment of the sliding pin, and the tension applied by the high-tension tester.

-

Testing Conditions: Determine the appropriate test parameters based on the intended use of the textile. For example, in consumer goods, lower tear strength values are acceptable. However, higher tear strength values are preferred for industrial applications.

-

Record Test Data: Keep detailed records of all test results, including the weight of the sample, the force applied, and the distance traveled during the tear process. This data can be used to evaluate material consistency and quality over time.

Case Study: Let's consider a scenario where a manufacturer of outdoor apparel needed to demonstrate the durability of their fabric against common weather elements such as rain, snow, and wind. They chose to conduct tear tests using ASTM D638 and ASTM D1925 standards, applying various loads and speeds to simulate various weather conditions. They also monitored the moisture content of the samples during the testing process to ensure consistency. The results were compared to industry standards and showed that their fabrics had significantly higher tear strength than expected, which met their customers' demands for long-lasting outdoor apparel.

Conclusion: Tear test standards provide a benchmark for evaluating textile quality, ensuring that garments and other textile products are durable and resistant to tearing. Following recommended practices and understanding the nuances of each test method can help businesses meet their customers' expectations and stay ahead of the competition. By consistently testing and monitoring their textiles, companies can confidently claim superior product durability and reliability.

纺织品作为日常生活中不可或缺的服装材料,其质量直接关系到消费者的使用体验和安全,为了确保纺织品在各种使用场景下的耐用性和安全性,对纺织品撕破强度进行检测是非常必要的,本篇文章将详细介绍纺织品撕破强度检测的标准以及相关案例分析。

纺织品撕破强度检测标准概述

检测目的

纺织品撕破强度检测的主要目的是评估纺织品在受到外力作用时能否保持其结构完整性,从而确保其在各种使用场景下的耐用性和安全性。

检测方法

根据相关标准和行业规范,纺织品撕破强度检测通常采用以下方法:

(1)拉伸试验:通过拉伸测试仪器对纺织品进行拉伸测试,观察其在拉伸过程中的形变情况,从而评估其撕破强度。 (2)断裂强度测试:通过施加一定的外力,使纺织品在短时间内断裂,从而评估其撕裂强度。

检测标准

(1)标准依据:根据国家和行业标准,纺织品撕破强度检测标准主要包括以下内容:

a. 撕裂强度标准值:根据不同材质和用途,设定相应的撕裂强度标准值。 b. 断裂伸长率标准值:用于评估纺织品在拉伸过程中的形变情况。

(2)案例分析:在实际应用中,不同材质和用途的纺织品对撕裂强度和断裂伸长率的要求可能有所不同,某些高纤维含量或特殊工艺处理的纺织品可能需要更高的撕裂强度来满足特定的使用要求,在实际检测过程中,需要根据具体情况制定相应的检测标准。

案例说明

以某品牌纺织品为例,详细说明其撕破强度检测标准和案例。

材料特性

该品牌纺织品主要采用高品质纤维和特殊工艺处理,具有较高的强度和耐磨性,根据材料特性,该品牌纺织品在撕裂强度和断裂伸长率方面具有较高的要求。

检测标准与过程

(1)撕裂强度检测标准:根据国家和行业标准,该品牌纺织品撕裂强度标准值应不低于某个数值,具体数值可能因不同材质和用途而有所不同,在实际检测过程中,可以采用拉伸试验和断裂强度测试等方法进行检测。

(2)案例分析:在该品牌纺织品的生产过程中,采用了先进的生产工艺和检测设备,对每一批次的纺织品进行了严格的检测,通过拉伸试验和断裂强度测试等方法,该品牌纺织品在各项指标上均符合相关标准和要求,从而保证了其产品的质量和安全性。

纺织品撕破强度检测是确保纺织品质量和安全性的重要手段,在实际应用中,需要根据不同材质和用途的纺织品特点,制定相应的检测标准和方法,还需要加强检测过程的管理和控制,确保检测结果的准确性和可靠性,通过不断改进和提高纺织品撕破强度检测标准和方法,可以更好地保障消费者的使用体验和安全。

Articles related to the knowledge points of this article:

The Story of the佛山市禅城区颖兴纺织品批发部