The阜阳纺织厂疫情应对,策略与挑战

The Fengyuan Textile Factory, during the COVID-19 pandemic, implemented a series of strategies aimed at minimizing risks and ensuring production continuity. The primary focus was on strict adherence to safety protocols, including regular health checks, social distancing measures, and the implementation of enhanced sanitation procedures. In addition, the factory diversified its supply chain by sourcing raw materials from different suppliers and establishing backup production lines in case of any disruptions. Despite these efforts, the pandemic presented several challenges for the factory, including labor shortages and increased operational costs associated with implementing safety measures. However, through a collective effort and resource allocation adjustments, the factory was able to overcome these obstacles and continue operating within the confines of the COVID-19 guidelines.

本文目录导读:

- Early Detection: A Key to Success

- Communication and Engagement: Enhancing Employee Understanding and Support

- Strategic Decisions: Prioritizing Safety While Minimizing Impact

- Challenges Faced and Future Outlook

In the midst of the COVID-19 pandemic, one factory in China's Fuyang city, a major textile hub, has faced unprecedented challenges. The Guizhou Textile Factory, a renowned manufacturer with over ten decades of history, was forced to shut down its doors due to a series of health issues within its workforce. This case highlights the importance of early detection and proactive measures taken by factories like Guizhou Textile Factory to mitigate the impacts of the pandemic.

Early Detection: A Key to Success

One of the key factors in Guizhou Textile Factory's successful response to the pandemic was its ability to detect the initial signs of infection among its employees. Unlike many other companies that waited until symptoms appeared before implementing any preventive measures, the textile factory took action early on.

Timeline of Action Taken

-

Pre-Pandemic Measures: Guizhou Textile Factory implemented strict hygiene practices, including regular hand washing, sanitizing workstations, and providing personal protective equipment (PPE) for all staff.

-

Symptom Checklist: The factory developed a symptom checklist that employees were required to complete daily to identify potential exposure.

-

Employee Screening: Before returning to work, employees were required to undergo a health screening, including temperature checks and a questionnaire to assess their recent travel history.

-

Contact Tracing: If an employee tested positive for the virus, the factory initiated a contact tracing process to identify and isolate any close contacts who may have been exposed.

Results: Thanks to these proactive measures, the factory was able to detect a small number of cases before they could spread throughout the facility or affect other employees. This early detection allowed for quick containment efforts and minimized the potential for further outbreaks.

Communication and Engagement: Enhancing Employee Understanding and Support

Effective communication is crucial in managing a crisis, and Guizhou Textile Factory recognized this during the pandemic. The company communicated clearly about the steps it was taking to prevent the spread of the virus and how each employee could contribute to maintaining safety.

Communication Tools and Channels: Regular updates via email and social media platforms were sent out, as well as direct phone calls to those who needed to know more. These channels allowed employees to ask questions and voice concerns directly with management.

Engagement Programs: In addition to informational campaigns, the factory also organized virtual team-building activities and wellness workshops to boost morale and promote a sense of community within the workplace.

Strategic Decisions: Prioritizing Safety While Minimizing Impact

When making decisions amidst a pandemic, it is important to strike a balance between minimizing risks and ensuring productivity. The Guizhou Textile Factory made strategic choices that helped maintain operations while protecting employees and the public at large.

Flexible Work Arrangements: To minimize the risk of transmission, the plant implemented flexible work schedules, allowing employees to work from home where possible.

Remote Work Policy: For those unable to return to work due to illness, the factory offered remote work options. This not only protected employees but also allowed them to continue working from home while minimizing the risk of exposure for their colleagues.

Supply Chain Diversification: By diversifying the sources of raw materials, the factory reduced the risk of relying solely on a single supplier and ensured that supply chain disruptions did not impact production.

Continuous Training: The factory continued to provide training on pandemic-related topics, such as proper PPE use, hygiene protocols, and emergency preparedness, to keep up with changing guidelines and best practices.

Challenges Faced and Future Outlook

Despite the successes, the Guizhou Textile Factory faced significant challenges during the pandemic, including labor shortages, supply chain disruptions, and financial pressures. However, the company demonstrated resilience and adaptability in addressing these challenges.

-

The factory successfully managed to keep up with its production schedule despite the challenges, thanks to its effective communication strategies and strategic decision-making.

-

It is now focusing on enhancing its digital transformation capabilities to become more sustainable and resilient in future crises.

-

Guizhou Textile Factory is committed to investing in research and development to create more innovative solutions that will help it navigate future pandemics and other challenges.

By leveraging its strengths and adapting swiftly to new realities, Guizhou Textile Factory is poised to emerge stronger than ever before. Its story serves as an inspiration for other companies facing similar situations during this unprecedented time.

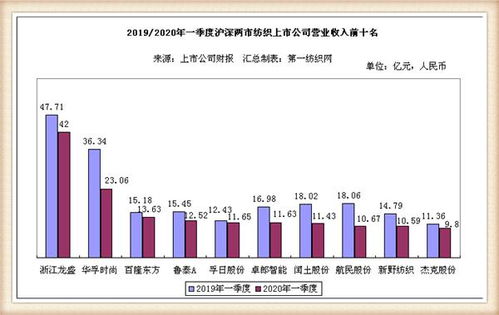

背景介绍

阜阳纺织厂近期面临严重的疫情挑战,随着全球疫情的持续蔓延,工厂的生产和员工健康安全受到严重影响,工厂采取了多项措施来应对这一挑战,包括加强防疫措施、调整生产计划等。

疫情现状

- 员工健康状况:工厂员工在疫情期间表现出不同程度的健康问题,包括部分员工出现发热、咳嗽等症状。

- 生产状况:工厂的生产受到严重影响,订单量大幅减少,生产进度受到挑战。

- 物资储备:工厂在物资储备方面面临困难,需要确保原材料、设备等物资的供应稳定。

应对措施

- 防疫措施:工厂加强了防疫宣传,提高了员工的防疫意识,同时采取了严格的消毒措施,确保生产环境的卫生安全。

- 生产调整:工厂调整了生产计划,优先保障关键岗位和关键工序的生产,同时采取灵活的生产策略,适应市场需求的变化。

- 物资保障:工厂加强了物资采购和储备管理,确保原材料、设备等物资的稳定供应,工厂还积极与供应商沟通,寻求更多的合作机会,以缓解物资短缺的问题。

案例分析

为了更好地说明疫情期间阜阳纺织厂的应对措施和效果,我们可以引入一个英文案例。

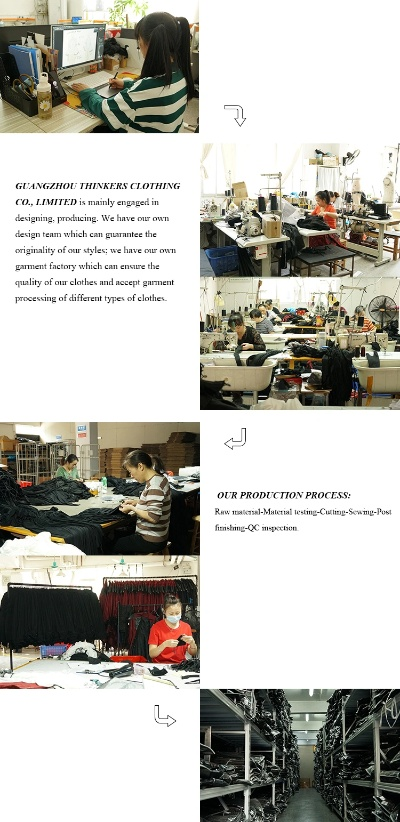

阜阳纺织厂与供应商的合作案例

在疫情期间,阜阳纺织厂与多家供应商建立了紧密的合作关系,共同应对疫情带来的挑战,工厂与供应商共同制定了一系列的生产计划和采购策略,以确保原材料和设备的稳定供应,工厂还积极与供应商沟通,寻求更多的合作机会,以缓解物资短缺的问题,通过与供应商的合作,工厂成功地应对了疫情带来的挑战,保证了生产的稳定进行。

阜阳纺织厂在疫情期间面临着严峻的挑战,但通过加强防疫措施、调整生产计划、加强物资保障等多项措施,成功地应对了这一挑战,工厂在应对疫情的同时,还积极调整生产策略,适应市场需求的变化,以保持生产的高效和稳定,工厂还加强了与供应商的合作,共同应对疫情带来的挑战,这些措施和经验对于其他企业应对类似疫情挑战具有一定的参考价值。

Articles related to the knowledge points of this article:

Exploring the Rich Tapestry of Rushans Handicraft Textiles

The Disaster That Strands Textile Factories:A Case Study

Navigating the World of Textiles:A Tale of Women in the Pulp Mill

The 22-Year-Old Textile Factory:A Journey Through Youth and Potential