Types of Textile Printing Machines

Textile printing machines are essential tools for the textile industry, enabling the production of various types of textile products with intricate designs. These machines come in different configurations and capabilities, catering to a wide range of applications. The primary types of textile printing machines include rotary screen printing, embroidery machines, and digital printing technologies. Rotary screen printing is a traditional method that involves using a screen to transfer ink onto the fabric, while embroidery machines use needles to create detailed patterns on the fabric. Digital printing technology, on the other hand, utilizes computer-controlled machines to produce high-quality images directly onto fabric or other materials. Each type of printing machine has its unique advantages and limitations, making it crucial for manufacturers to choose the right equipment based on their specific needs and budget.

Introduction: Textile printing machines play a crucial role in the textile industry, enabling manufacturers to produce high-quality printed fabrics. These machines come in various types and configurations, each with its unique features and applications. In this article, we will explore some of the most common types of textile printing machines and their respective advantages and disadvantages.

Offset Printers Offset printers are the most commonly used type of textile printing machine. They use a plate made from a special ink-resistant material (offset paper) that is coated with an ink layer. The ink layer is then transferred onto the fabric using a heated roller. This process results in a high-quality, uniform print on the fabric.

Advantages:

- High quality prints

- Versatile design for different fabrics and colors

- Cost-effective compared to other types of printing machines

Disadvantages:

- Limited color options compared to digital printing machines

- Slow production speeds compared to digital printing machines

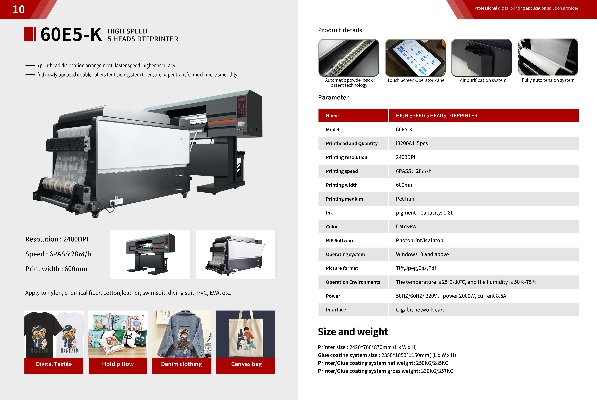

Digital Printers Digital printing machines use electronic imaging technology to create prints on fabrics. These machines can produce high-resolution images and offer a wide range of color options.

Advantages:

- High resolution and detail

- Wide range of color options

- Continuous production capabilities

Disadvantages:

- High initial investment cost

- Limited production capacity compared to offset printers

Screen Printing Machines Screen printing machines use a mesh screen to transfer ink from a stencil onto the fabric. This process results in a patterned print that can be easily customized.

Advantages:

- Easy customization of designs

- Low initial investment cost

- Can produce small quantities of prints

Disadvantages:

- Limited color options compared to digital printing machines

- Slow production speeds compared to digital printing machines

Embossing Machines Embossing machines use a hot iron to create raised patterns on the fabric surface. This process adds texture and depth to the printed design.

Advantages:

- Creates a three-dimensional effect

- Can be used to add texture to printed designs

Disadvantages:

- Limited color options compared to digital printing machines

- Slow production speeds compared to digital printing machines

Heat Press Machines Heat press machines use a hot iron to fuse ink onto the fabric surface. This process creates a permanent, one-time print.

Advantages:

- Permanent prints that cannot be removed once applied

- Can be used for a variety of materials

Disadvantages:

- Limited color options compared to digital printing machines

- Slow production speeds compared to digital printing machines

Case Study: Consider the case of a textile company that specializes in producing high-quality printed clothing. They needed to produce a new collection of printed shirts using digital printing machines. After researching different types of digital printing machines, they decided to invest in a high-resolution, color-accurate, and continuous production digital printing machine. The investment was significant, but it proved to be worth it as the company was able to produce a wide range of vibrant, detailed prints quickly and efficiently.

Conclusion: Textile printing machines come in various types and configurations, each with its unique advantages and disadvantages. Manufacturers must carefully consider their needs and budget when choosing the right type of printing machine for their production needs. By doing so, they can ensure that they are producing high-quality, visually appealing products that meet their customers' expectations.

在纺织行业中,纺织品印刷机是不可或缺的设备之一,不同类型的印刷机适用于不同的生产需求和工艺要求,本文将详细介绍纺织品印刷机的类型及其特点,并通过案例分析来说明它们在实际生产中的应用。

纺织品印刷机类型概述

机械式印刷机

机械式印刷机是传统的纺织品印刷设备,主要依靠机械传动和控制系统来实现印刷功能,其优点是操作简便、稳定性好,适用于批量生产,常见的机械式印刷机类型包括平版印刷机、凸版印刷机等。

(1)平版印刷机

平版印刷机是一种使用平版材料进行印刷的设备,其印刷原理是通过墨水在平版材料上的转移来实现图案的印刷,平版印刷机适用于各种类型的纺织品,如棉布、丝绸等。

(2)凸版印刷机

凸版印刷机是一种使用凸版材料进行印刷的设备,其印刷特点是图案清晰、色彩鲜艳,适用于高要求、高质量的纺织品生产,在印染、印花等领域,凸版印刷机得到了广泛应用。

电子式印刷机

电子式印刷机是一种现代化的纺织品印刷设备,主要利用数字技术进行控制,其优点是自动化程度高、生产效率高,适用于个性化、定制化的纺织品生产,常见的电子式印刷机类型包括数字喷墨印刷机、激光直接制版机等。

(1)数字喷墨印刷机

数字喷墨印刷机是一种利用数字喷墨技术进行图案印刷的设备,其优点是图案清晰、色彩鲜艳,适用于各种类型的纺织品,如印花、绣花等,数字喷墨印刷机还具有环保、节能的特点,符合现代纺织业的绿色生产理念。

(2)激光直接制版机

激光直接制版机是一种利用激光技术进行制版的设备,其优点是制版精度高、速度快,适用于大规模生产,在印染、印花等领域,激光直接制版机可以快速生成高质量的印版,提高生产效率。

案例分析

机械式印刷机案例

某纺织企业采用机械式印刷机进行纺织品生产,该企业主要生产各种类型的棉布和丝绸制品,需要满足不同客户的需求和品质要求,根据企业的实际生产需求,该企业选择了适合的机械式印刷机类型,如平版印刷机,用于批量生产,该机械式印刷机的优点是操作简便、稳定性好,能够满足企业的日常生产需求,该企业还采用了先进的工艺和技术,提高了产品的质量和生产效率。

电子式印刷机案例

某服装品牌采用电子式印刷机进行纺织品生产,该品牌注重个性化、定制化的纺织品生产,需要快速生成高质量的印版,该品牌选择了数字喷墨印刷机,该设备的优点是图案清晰、色彩鲜艳,能够满足品牌对纺织品品质和外观的要求,该设备还具有环保、节能的特点,符合现代纺织业的绿色生产理念,在生产过程中,该设备还能够实现自动化控制,提高了生产效率和质量。

纺织品印刷机的类型多种多样,每种类型都有其适用的生产环境和工艺要求,在选择纺织品印刷机时,需要根据企业的实际生产需求和工艺要求来选择适合的机型,在实际生产中,还需要注意设备的维护和保养,以保证设备的稳定性和可靠性,通过案例分析可以看出,不同类型的纺织品印刷机在实际生产中的应用效果也不同,需要根据实际情况进行选择和应用。

Articles related to the knowledge points of this article:

The Magic of Golden Olive Textiles

The Prospects of Qualified Textile Products in Shanghais Songjiang District