Understanding the Standards for Textile Weight Measurement

: Understanding the Standards for Textile Weight Measurement,This article aims to provide an in-depth understanding of textile weight measurement standards. The first section discusses the importance of accurate weight measurements in textile production and quality control. It explains how these measurements are used to determine the quality and consistency of textile products.,The second section focuses on the various methods used to measure textile weight. These methods include weighing machines, electronic scales, and other specialized equipment. Each method has its advantages and disadvantages, and the choice of method depends on the specific requirements of the textile product being produced.,The third section examines the factors that affect textile weight measurements, such as material composition, thickness, and density. It also discusses how these factors can impact the accuracy and reliability of the measurements.,Finally, the fourth section provides practical tips for ensuring accurate textile weight measurements. This includes proper equipment maintenance, calibration of scales, and training of personnel involved in the measurement process.,In conclusion, understanding the standards for textile weight measurement is critical for ensuring consistent and high-quality textile products. By following the guidelines outlined in this article, manufacturers and quality control personnel can ensure accurate and reliable measurements.

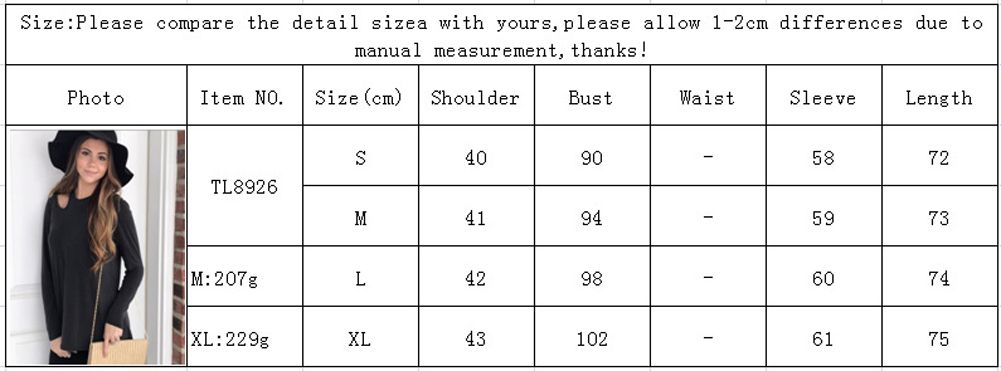

Introduction: In the world of textiles, the weight or "grammage" of a fabric is one of the most critical measurements. It not only affects the cost and quality of the product but also determines its functionality and durability. The importance of accurate weight measurement cannot be overstated, as it directly impacts the performance of garments and other textile products. In this article, we will explore the standards for textile weight measurement and how they are measured using a table. We will also discuss an example to illustrate the practical application of these standards in real-life scenarios.

Textile Weight Measurement Standards:

American Metric System (ASTM): The ASTM standard is widely used in the United States and Canada. It defines the following textile weight measurement standards:

| Fabric | Gram/m² |

|---|---|

| Cotton | 200-400 |

| Polyester | 350-600 |

| Nylon | 400-700 |

| Rayon | 250-500 |

| Wool | 300-500 |

These values represent the average weights of different types of fabrics. For example, a cotton fabric with a density of 300 grams per square meter would have a weight of 300 g/m².

International Organization for Standardization (ISO): The ISO standard is used globally and includes the following textile weight measurement standards:

| Fabric | Gram/m² |

|---|---|

| Cotton | 200-400 |

| Polyester | 350-600 |

| Nylon | 400-700 |

| Rayon | 250-500 |

| Wool | 300-500 |

Similar to the ASTM standard, these values represent the average weights of different types of fabrics. For instance, a wool fabric with a density of 300 grams per square meter would have a weight of 300 g/m².

European Norms (EN): The European Norms for textile weight measurement include the following standards:

| Fabric | Gram/m² |

|---|---|

| Cotton | 200-400 |

| Polyester | 350-600 |

| Nylon | 400-700 |

| Rayon | 250-500 |

| Wool | 300-500 |

These values are similar to the ISO and ASTM standards, but they may vary slightly depending on the country of origin or the specific region within that country. For example, a wool fabric with a density of 300 grams per square meter would have a weight of 300 g/m² in some regions, while in others it might be higher or lower.

Measuring Textile Weight:

To measure the weight of a textile fabric, you can use a digital scale that has a weight measurement feature. Here's how to do it:

-

Place the fabric on a flat surface, preferably on a clean, smooth surface like a tabletop or a weighing paper.

-

Set the scale to zero and place the fabric on top of it.

-

Press down firmly on the fabric to ensure it is evenly distributed across the scale.

-

Read the weight displayed on the scale. If you need more accuracy, repeat the process several times until you get a consistent reading.

Example:

Let's say you have a sample of polyester fabric that you want to measure its weight. You can follow the above steps and find out that the average weight of the sample is 350 grams per square meter. This means that each square meter of the fabric weighs 350 grams.

Practical Application:

Textile weight measurement is crucial for various industries such as fashion, home furnishings, and apparel manufacturing. For example, when designing clothing, knowing the weight of different fabrics is essential to determine how much material is needed and to calculate the price accordingly. Similarly, when purchasing textile materials, knowing the weight of different fabrics helps buyers make informed decisions about their budget and design requirements.

Conclusion:

In conclusion, textile weight measurement is an important aspect of textile industry operations. By understanding the standards for textile weight measurement and using appropriate tools, businesses can ensure that their products meet customer needs and expectations. Whether you're a manufacturer, retailer, or designer, having accurate textile weight measurements is key to success in today's competitive market.

随着纺织品行业的快速发展,纺织品的质量和准确性成为了消费者关注的焦点,为了确保纺织品的质量和一致性,制定纺织品克重误差标准显得尤为重要,本篇文章将详细介绍纺织品克重误差的标准以及相关案例分析。

纺织品克重误差标准概述

-

定义:纺织品克重误差是指纺织品在测量过程中产生的重量差异,通常以克为单位衡量,根据相关行业标准,纺织品克重误差标准主要包括以下内容:

- 测量方法:采用国际通用的测量方法和技术标准。

- 允许误差范围:根据纺织品种类、用途和市场需求,设定合理的误差范围。

- 检测机构:具备相关资质和检测能力的检测机构。

-

相关案例分析:为了更好地理解纺织品克重误差标准,我们可以结合实际案例进行分析,某品牌在生产过程中,为了确保纺织品的质量和一致性,制定了详细的克重误差标准,并严格按照标准进行检测,该品牌还与多家检测机构合作,确保检测结果的准确性和可靠性。

纺织品克重误差的测量方法

- 测量仪器:采用先进的测量仪器,如电子天平、激光测重仪等。

- 测量步骤: a. 选择合适的测量仪器和测量方法。 b. 对纺织品进行准确的称重。 c. 根据测量结果,计算出克重误差值。

- 注意事项:在测量过程中,应确保测量环境的稳定性和准确性,避免外界因素对测量结果的影响。

纺织品克重误差的标准案例分析

某品牌纺织品克重误差标准案例 该品牌在生产过程中,制定了详细的克重误差标准,具体内容如下:

- 测量方法:采用国际通用的测量方法和技术标准。

- 允许误差范围:对于不同种类的纺织品,设定了合理的误差范围,对于纯棉纺织品,允许重量误差±0.5%;对于丝绸纺织品,允许重量误差±1%,该品牌与多家检测机构合作,严格按照标准进行检测,确保了纺织品的质量和一致性。

案例分析:在实际应用中,纺织品克重误差标准的应用范围广泛,在服装、家居装饰等领域,纺织品的质量和一致性对于消费者的舒适度和美观度至关重要,制定纺织品克重误差标准对于保障产品质量、提高消费者满意度具有重要意义。

提高纺织品克重误差控制水平的措施

- 加强质量管理体系建设:企业应建立完善的质量管理体系,明确质量标准和检测流程,确保产品质量和一致性。

- 强化检测机构建设:加强检测机构的建设和管理,提高检测机构的检测能力和技术水平,与多家检测机构合作,确保检测结果的准确性和可靠性。

- 提高从业人员素质:加强对从业人员的培训和管理,提高从业人员的技术水平和职业道德素质,建立完善的考核机制,确保从业人员能够满足质量标准和检测要求。

制定纺织品克重误差标准对于保障纺织品的质量和一致性具有重要意义,在实际应用中,企业应加强质量管理体系建设、强化检测机构建设、提高从业人员素质等措施,确保纺织品的质量和一致性,在实际操作中,应严格按照标准进行检测,确保检测结果的准确性和可靠性。

Articles related to the knowledge points of this article:

Smart Textiles:The Revolutionizing Power of Temperature-Responsive Fabrics

Exploring the World of Textiles at Changzhou Ke Teng Textile Trading Co.Ltd.