The Art of Textiles:From Raw Materials to Fashionable Clothing

The process of turning raw materials into fashionable clothing is a complex and meticulous one. From the selection of high-quality yarns to the careful embroidery or stitching techniques, every step is essential in achieving the desired aesthetic and functionality. The use of innovative dyeing methods and printing techniques has also revolutionized the textile industry, allowing for a wider range of colors and designs. Additionally, the integration of sustainable practices has become increasingly important in today's market, as consumers demand more eco-friendly and ethically sourced products. As technology continues to advance, we can expect to see even greater innovations in the field of textiles, ensuring that our clothing remains stylish and functional for years to come.

In the world of textiles, the journey from raw materials to fashionable clothing is a complex one that involves precision, craftsmanship, and innovation. Textiles are not just fabrics; they are an integral part of our daily lives, reflecting cultural identity, aesthetic preferences, and technological advancements. In this article, we will explore the various stages involved in the manufacturing of textiles, including the selection of raw materials, the process of spinning and weaving, and the final product's design and application. We will also highlight some successful cases in the industry, showcasing how technology and creativity have transformed the textile sector.

Textiles are made from a wide range of materials, including cotton, wool, silk, polyester, and nylon. Each material has its unique properties that determine its suitability for specific uses. For example, cotton is soft and breathable, making it ideal for creating comfortable clothing. On the other hand, wool is warm and durable, making it popular for winter wear. Silk, with its lustrous texture and delicate feel, is often used for luxurious items such as scarves and tablecloths. Polyester, which is derived from petroleum, is strong and resistant to wear and tear, making it suitable for outdoor clothing and sportswear.

The first step in the textile manufacturing process is selecting the right raw materials. This decision is based on factors such as cost, availability, and quality. Once the raw materials have been chosen, they are processed into yarns or threads. Yarn production involves spinning, where the fibers are twisted together to form a continuous thread. The spinning process can be done manually or using machines, depending on the desired level of accuracy and consistency.

Once the yarn is produced, it is ready for weaving. Weaving involves interlacing the yarns to create a fabric. There are several types of weaving, including simple weave, twill weave, and purl weave, each with its own characteristics. The choice of weaving technique depends on the desired look and functionality of the finished product.

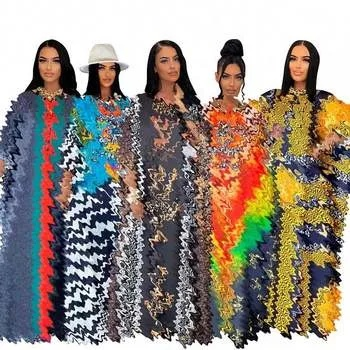

After the weaving process, the fabric undergoes further processing to enhance its appearance and performance. This includes treatments such as dyeing, printing, and finishing. Dyeing involves applying color to the fabric using chemicals or heat. Printing involves adding patterns or designs to the fabric using screens or other methods. Finishing involves smoothing out any rough edges or impurities in the fabric and enhancing its durability.

To showcase the importance of technology in textile manufacturing, let us take a look at the case of Tencel™. Tencel™ is a brand of lyocell fiber, which is derived from wood pulp. Unlike traditional cotton, which requires pesticides to grow, lyocell fiber can be grown without harmful chemicals. This makes Tencel™ an eco-friendly alternative to conventional textiles. Tencel™ is also highly absorbent, making it ideal for use in sportswear and underwear.

In addition to Tencel™, there are many other innovative textiles being developed today. For example, microfibers are being used in personal care products such as shampoo bars and facial wipes. These microfibers are small enough to penetrate even the most delicate skin pores, providing effective cleaning without harsh chemicals. Another example is the development of antimicrobial textiles, which can kill bacteria and viruses on contact. These textiles are ideal for use in hospitals, schools, and other public spaces.

Another trend in textile manufacturing is the integration of technology with fashion. With the help of advanced computer-aided design (CAD) software, designers can create intricate patterns and designs that would otherwise be impossible to achieve with traditional manual techniques. Additionally, digital printing technology allows for high-quality prints to be applied to textiles with minimal waste and minimal environmental impact.

In conclusion, textiles are more than just clothes; they are an integral part of our lives, reflecting our culture, aesthetic preferences, and technological advancements. From the selection of raw materials to the final product's design and application, textile manufacturing involves a complex process that requires precision, craftsmanship, and innovation. By exploring the different stages involved in the process and highlighting some successful cases in the industry, we can gain a better understanding of the art and science behind textiles.

纺织品的制造概述

纺织品的制造是一个复杂且多样的过程,涵盖了从原材料收集、加工到成品出库的各个环节,随着科技的进步和人们对舒适度、美观度和环保性的追求,纺织品的制造技术也在不断发展和创新。

纺织品的制造流程

- 原材料收集:纺织品的制造首先从各种天然或合成纤维原料开始,这些原料可以是棉花、羊毛、丝绸、涤纶等。

- 初步加工:根据纺织品的种类和设计要求,对原料进行初步的剪裁、缝制或编织,这包括织造、印花、染色等工艺。

- 机器生产:使用各种纺织机械和设备进行自动化生产,这包括织布机、印花机、染缸等。

- 质量控制:在纺织品的制造过程中,严格控制质量标准,确保产品的质量和性能符合要求。

- 成品检验:在产品出库前,进行严格的成品检验,确保产品符合质量标准。

案例说明

以一家知名纺织品制造商为例,介绍其纺织品的制造过程和技术创新。

-

原材料选择 该制造商主要使用高品质的天然纤维和合成纤维作为原材料,他们注重环保和可持续性,选择那些对环境影响较小的原料。

-

技术创新 该制造商在纺织品的制造过程中采用了先进的自动化技术和智能化设备,他们使用智能织布机,可以根据设计要求快速准确地完成织造任务,他们还采用了先进的染色技术,可以更好地控制染料的颜色和均匀度,他们还注重绿色生产,采用环保材料和工艺,减少对环境的污染。

-

出库检验 在产品出库前,该制造商会对产品进行严格的检验,他们采用先进的检测设备和技术,对产品的质量、性能和外观进行全面检测,他们还会对产品的环保性能进行检测,确保产品符合国家和国际的环保标准。

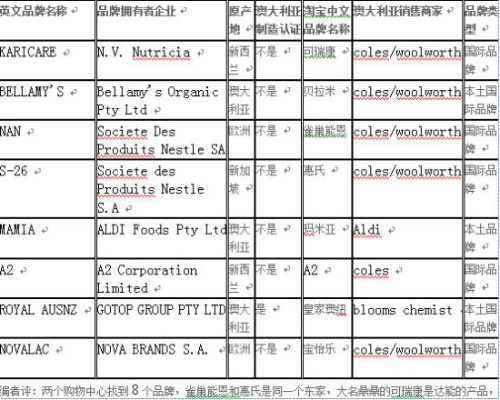

英文表格补充说明

以下是一个英文表格,用于进一步说明纺织品的制造过程和技术创新:

纺织品制造流程与技术创新说明

| 步骤 | 描述 | 技术创新 | 示例材料 |

|---|---|---|---|

| 原材料收集 | 从各种天然或合成纤维原料开始 | 采用先进的自动化技术和智能化设备 | 棉花、羊毛、丝绸、涤纶等 |

| 初步加工 | 根据设计要求进行剪裁、缝制或编织 | 使用智能织布机等先进设备 | |

| 机器生产 | 使用纺织机械和设备进行自动化生产 | 采用绿色生产技术,使用环保材料和工艺 | |

| 质量控制 | 严格控制质量标准 | 采用先进的检测设备和技术 | |

| 出库检验 | 对产品进行全面检测和环保性能检测 | 采用先进的检测设备和技术,确保产品符合国家和国际的环保标准 |

纺织品的制造是一个复杂而重要的过程,需要不断的技术创新和改进,在未来的发展中,随着人们对舒适度、美观度和环保性的追求不断提高,纺织品的制造技术也将不断发展和创新,企业也需要注重环境保护和可持续发展,采取绿色生产和技术创新,为人类的可持续发展做出贡献。

Articles related to the knowledge points of this article:

The Review of Yirui Textile Brand and Its Prices

Textile Industry in Global Perspective

The Art of Crafting Luxurious Living with Liang Textiles

The Art of Crafting Quality Textiles:An Exploration with Qing Wen Textiles