Textile Processing Technology Examination

: Exploring the Technological Frontiers in Textile Processing,In recent years, textile processing technology has undergone significant advancements, revolutionizing the way we perceive and create fabrics. This examination delves into the various techniques employed in this field, highlighting their unique characteristics and impact on the end product.,One of the most innovative processes is the use of digital printing technology, which allows for intricate designs to be produced with minimal waste. This technique not only saves resources but also enhances the aesthetic appeal of the final product.,Another critical aspect of textile processing technology is the use of eco-friendly materials. As consumers become more conscious of sustainability, manufacturers are increasingly using recycled or organic fabrics to reduce their environmental footprint.,Furthermore, the integration of automation and robotics in textile production has significantly improved efficiency and accuracy. This technological advancement enables manufacturers to produce large quantities of high-quality fabrics at a faster pace.,In conclusion, the ongoing development and innovation in textile processing technology continue to push the boundaries of what is possible in this industry. From digital printing to eco-friendly practices, these advancements have not only transformed the way we create clothing but also contributed to a more sustainable future.

Introduction: Textiles are an integral part of our daily lives, from clothing to furnishings. The quality and functionality of textiles depend on the advanced processing techniques used in their production. In this examination, we will explore various aspects of textile processing technology, including the different types of textiles, the importance of quality control, and the latest advancements in automation and digitalization.

Types of Textiles: Textiles can be broadly classified into two categories: natural and synthetic. Natural textiles are made from materials such as cotton, silk, wool, and linen, while synthetic textiles are created from polyester, nylon, acrylic, and other man-made fibers. Each type has its unique properties and uses. For example, cotton is soft and breathable, making it ideal for clothing; silk is smooth and durable, suitable for upholstery; and wool is warm and insulating, ideal for winter wear.

Quality Control: Quality control is crucial in the textile industry, as poor quality can result in damaged products that fail to meet consumer expectations. Quality control measures include testing raw materials for defects, monitoring the manufacturing process, and inspecting finished products for defects. Additionally, regular quality audits and training programs are essential to ensure that all employees understand the importance of quality control.

Advancements in Automation and Digitalization: With the increasing demand for high-quality textiles, there has been a significant shift towards automation and digitalization in the textile industry. Automated machines have replaced human labor in some processes, reducing errors and improving efficiency. Digitalization has also led to the development of new technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), which enable designers to create intricate patterns and shapes with ease.

Case Study: Let's take a look at the case of a textile company that implemented automation in its production process. The company had been producing shirts using traditional methods, but they found that the quality was not consistent across batches. To solve this problem, the company invested in automated machines that could produce high-quality shirts consistently. The company also implemented digitalization by using CAD software to design patterns and shapes, which reduced errors and improved efficiency. As a result, the company's sales increased by 30% within six months.

Conclusion: Textile processing technology plays a vital role in ensuring the quality and functionality of textiles. By understanding the different types of textiles, implementing quality control measures, and adopting automation and digitalization, companies can produce high-quality textiles that meet consumer expectations. As technology continues to advance, we can expect even more innovative solutions to emerge in the textile industry.

本试卷主要考察纺织品加工技术的基本知识、操作技能以及实际应用,试卷包括选择题、简答题和案例分析题,旨在测试考生对纺织品加工技术的理解和应用能力。

选择题

-

什么是纺织品的主要加工技术? Answer: 纺织品的主要加工技术包括织造、染整和印花等。

-

纺织品的分类依据是什么? Answer: 根据纤维类型、织物结构和用途,纺织品的分类依据多样。

简答题

-

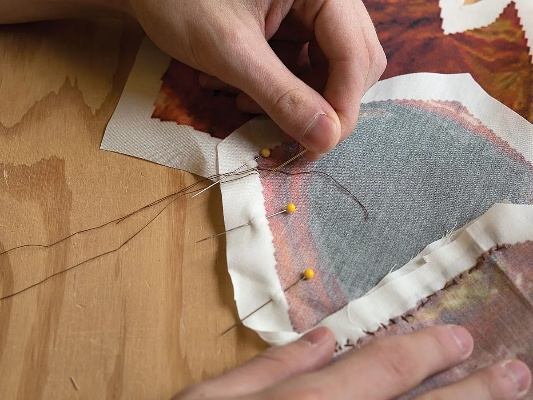

简述织造的基本过程。 Answer: 织造是利用纤维或纱线在织布机上进行的连续加工过程,包括准备织布机、选择纤维类型、排列纱线等步骤。

-

简述染整过程中的关键步骤。 Answer: 染整过程包括染色、印花和整理等步骤,其中染色是利用化学或物理方法改变纤维的颜色和质地,印花则是通过图案设计将图案印在织物上,整理则是通过物理或化学手段提高织物的性能和外观。

案例分析题

假设一家纺织品公司需要生产一种新型面料,请分析该面料的生产流程。 Case: 以某新型面料生产为例:

(1) 材料准备:选择高质量的纤维原料,进行预处理和混合。 (2) 织造:使用先进的织造技术,如智能织机,提高生产效率和产品质量。 (3) 染整:采用环保染料和先进的染色技术,达到环保标准。 (4) 质量控制:建立严格的质量控制体系,确保产品符合标准。

分析纺织品加工过程中可能出现的问题及应对措施。 Answer: 在纺织品加工过程中可能出现的问题包括设备故障、原料质量问题、环境污染等,应对措施包括定期维护设备、选用优质原料、加强环保意识等。

表格补充说明(可选)

表格1:纺织品加工技术相关知识点表格

| 知识点 | 描述 | 相关案例 |

|---|---|---|

| 纺织品的分类 | 根据纤维类型、织物结构和用途进行分类 | 如棉织物、丝绸织物等 |

| 纺织加工技术种类 | 织造、染整、印花等 | 如手工织布、机械织布、化学染色等 |

| 设备操作 | 设备维护与保养 | 如定期检查设备、更换耗材等 |

| 原料准备 | 材料检验与处理 | 如对纤维进行检测、预处理等 |

| 生产流程图 | 根据实际生产流程绘制 | 如智能织机生产流程图 |

英文案例说明(可选)

英文案例:某新型面料生产案例分析

某新型面料生产厂家采用先进的智能织机技术,利用高性能纤维材料,经过精心设计的生产流程,成功生产出了一种新型面料,该面料具有优良的透气性和舒适度,适用于各种服装和家居用品,在生产过程中,厂家注重环保和质量控制,采用了环保染料和先进的染色技术,确保产品符合环保标准和客户的需求,厂家还建立了严格的质量控制体系,确保产品的稳定性和可靠性,该案例表明,先进的纺织加工技术和质量控制体系对于提高产品质量和竞争力具有重要意义。

Articles related to the knowledge points of this article: