Common Textile Defects and Their Impact on Quality

"Common Textile Defects and Their Impact on Quality",Textile quality is a critical factor in the success of any textile product. However, common defects such as wrinkles, pilling, and color bleeding can significantly impact its overall appearance and functionality. These defects often result from poor manufacturing processes, improper materials selection, or inadequate quality control measures.,To address these issues, manufacturers must implement strict quality control protocols and employ advanced technology to minimize defects during production. Additionally, regular inspections and testing should be conducted to ensure that products meet industry standards and consumer expectations.,In conclusion, understanding the impact of common textile defects on quality is crucial for manufacturers seeking to produce high-quality textile products. By implementing effective quality control measures and utilizing advanced technology, manufacturers can reduce the occurrence of these defects and improve the overall performance of their products."

Introduction: Textiles, whether they be clothing, upholstery fabrics, or industrial materials, are an integral part of our daily lives. However, despite their importance, textile products can often suffer from various defects that affect their appearance, functionality, and durability. In this guide, we will explore some of the most common textile defects and how they impact quality.

I. Fabric Structure Issues

-

Looseness: This is a common issue where the fibers in the fabric do not hold together properly, leading to gaps or holes. Looseness can result in poor wear resistance and can even lead to tears during use.

-

Creases and Wrinkles: These occur when the fabric has been stretched or creased during manufacturing or storage. They can significantly reduce the aesthetic appeal of the product and may also affect its performance.

-

Bulge and Sagging: These are issues where the fabric sags or bulges excessively under pressure. They can make the product look unprofessional and may also affect its functionality.

-

Threading Errors: These occur when the threads are not properly aligned or sewn together. They can lead to loose edges or gaps, which can cause the fabric to come apart or become frayed over time.

-

Uneven Weaving: This occurs when the warp and weft threads are not woven consistently. It can lead to uneven patterns or colors, which can significantly affect the overall aesthetic appeal of the product.

II. Finishing and Treatment Issues

-

Pinholes: These are small openings in the fabric caused by imperfections during the finishing process. They can be filled with dye or treated to improve the appearance of the fabric.

-

Stains and Discoloration: These occur when the fabric absorbs liquids or chemicals, causing discoloration or staining. They can significantly affect the aesthetic appeal of the product and may also affect its functionality.

-

Burns and Scratches: These occur when the fabric is exposed to heat sources or sharp objects, causing damage to the fibers. Burns can lead to permanent changes in the color or texture of the fabric, while scratches can cause the fabric to come apart or become damaged over time.

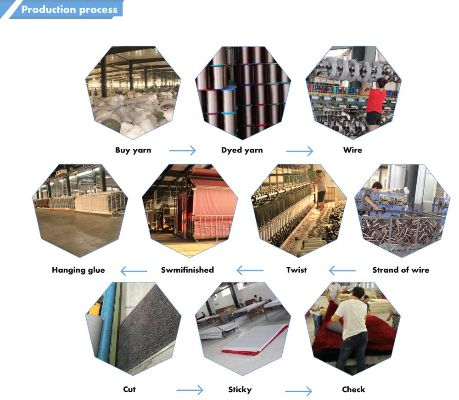

III. Manufacturing Process Issues

-

Dyeing and Printing Errors: These occur during the dyeing or printing process, causing discoloration or pattern errors. They can significantly affect the aesthetic appeal of the product and may also affect its functionality.

-

Weaving Errors: These occur during the weaving process, causing uneven patterns or colors. They can significantly affect the aesthetic appeal of the product and may also affect its functionality.

-

Stretching and Shrinkage: These occur during the manufacturing process, causing the fabric to become loose or shrink over time. They can significantly affect the aesthetic appeal of the product and may also affect its functionality.

IV. Environmental and Storage Issues

-

Moisture and Dust Buildup: These can cause stains or discoloration on the fabric, as well as damage to the fibers due to moisture or dust. Proper storage and handling are essential to prevent these issues.

-

Exposure to Chemicals: If the fabric is exposed to chemicals such as solvents or bleach, it can become damaged or fade over time. Proper storage and handling are essential to prevent these issues.

Conclusion: In conclusion, textile defects can have a significant impact on the quality of the product. By understanding the different types of defects and their impact on quality, manufacturers can take steps to minimize these issues and ensure that their products meet customer expectations.

纺织品织疵概述

纺织品织疵是纺织过程中常见的问题,英文中对应术语为“textile defects”,主要涉及织造过程中的各种疵点现象,这些疵点可能影响产品的外观和质量,因此需要引起足够的重视。

英文案例说明

以下是一个纺织品织疵的英文案例,以图表形式进行说明:

【英文案例】

织疵现象分析

在某纺织厂的生产过程中,经常出现一种织疵现象——织物条纹,这种条纹通常是由于织造过程中的机械或人为因素导致的,为了更好地理解织疵现象及其原因,我们可以使用以下的图表进行说明:

【表格说明】

| 织疵类型 | 描述 | 可能原因 | 解决方法 |

|---|---|---|---|

| 条纹织造 | 织物表面出现不规则的线条或图案 | 机械故障、操作不当 | 调整机械参数、优化操作流程 |

| 毛羽织疵 | 织物表面出现毛绒或羽毛状的疵点 | 纱线质量差、张力控制不当 | 提高纱线质量标准、优化张力控制系统 |

| 漏针织疵 | 织物出现不规则的孔洞或针脚断裂 | 针脚未正确穿入或针床不平整 | 检查针脚穿入情况、调整针床平整度 |

纺织品织疵的英文表述

在讨论纺织品织疵时,可以使用以下英文术语进行表述:

【英文表述】

- Textile Carding Faults - 纺织织疵,指在纺织品织造过程中出现的各种疵点现象。

- Patterning Defects - 织物条纹织疵,指织物表面出现不规则线条或图案的疵点。

- Hairy or Feathered Defects - 毛羽织疵,指织物表面出现毛绒或羽毛状的疵点。

- Missing Needle Defects - 漏针织疵,指在织物中出现不规则的孔洞或针脚断裂的疵点。

纺织品织疵的英文讨论点

在讨论纺织品织疵时,可以从以下几个方面进行深入探讨:

- 原因分析:探讨导致纺织品织疵的各种可能原因,如机械故障、操作不当、纱线质量差等。

- 影响评估:分析纺织品织疵对产品外观和质量的影响,以及是否会影响到产品的使用和销售。

- 解决措施:提出针对纺织品织疵的解决措施和方法,如调整机械参数、优化操作流程、提高纱线质量标准等。

- 案例研究:通过案例研究进一步加深对纺织品织疵的理解和认识。

总结与建议

纺织品织疵是纺织过程中常见的问题,需要引起足够的重视,在讨论纺织品织疵时,可以从原因分析、影响评估、解决措施等方面进行深入探讨,还可以通过案例研究进一步加深对纺织品织疵的理解和认识,建议企业在生产过程中加强质量控制和管理,提高产品质量和稳定性。

Articles related to the knowledge points of this article:

Textile Anti-Slitter Techniques:A Comprehensive Guide

The Fabric of Innovation:A Closer Look at Huatai Cotton Textiles

Exploring the Dynamics of Chargong Textiles by Road in Guangdong A Case Study