The Art of Label Printing in the Textile Industry

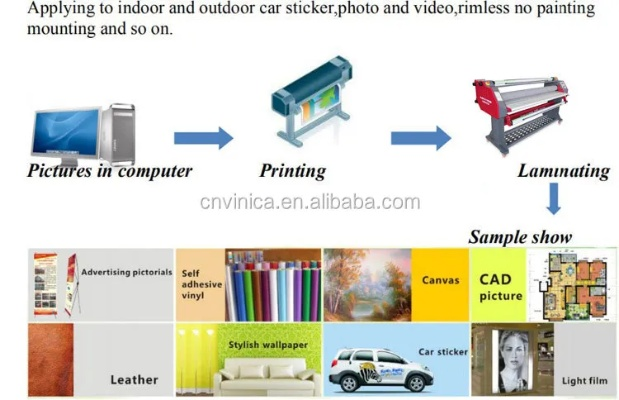

: The Art of Label Printing in the Textile Industry,In the textile industry, label printing is a crucial step that plays a significant role in brand recognition and product differentiation. This process involves the use of specialized equipment and techniques to create high-quality labels that are durable, aesthetically pleasing, and functional.,The first step in label printing is the design phase, where the artwork is created using various design tools such as CAD software or traditional methods like pen and paper. Once the design is finalized, it is then transferred onto the label material using a heat transfer printer or other printing methods.,The next step is the application of the label material to the textile product. This can be done manually or through automated machinery, depending on the size and complexity of the label. After the label is applied, it is inspected for any defects or errors and adjusted if necessary.,Finally, the finished label is packaged and shipped to retailers or distributors, where it will be used to identify and sell the product. In summary, label printing in the textile industry is an intricate process that requires careful attention to detail and quality control to ensure that products are accurately identified and sold.

In the textile industry, label printing is a crucial step that ensures the products are accurately identified and tracked. From small batch operations to large-scale production, label printing plays a vital role in brand recognition, product differentiation, and compliance with regulations. In this article, we will explore the various aspects of label printing in the textile industry, including its importance, techniques, challenges, and case studies.

At the heart of label printing in the textile industry lies the need for accurate and durable labels that can withstand harsh conditions and long-term use. This requires a thorough understanding of the materials used in the production process and the specific requirements of the label printing technology employed. For example, some textiles may require waterproof or anti-fade labels, while others may have a need for eco-friendly options.

One of the most common types of label printing used in the textile industry is digital label printing. This process involves using a digital printer to apply ink directly onto the fabric, resulting in a permanent label that can be easily read by customers. Digital label printing offers several advantages over traditional methods, such as faster turnaround times, improved accuracy, and reduced costs.

Another popular technique used in the textile industry is thermal label printing. This method involves using a heat-sensitive material to create a label that adheres to the fabric. The labels are then heated to permanently bond to the fabric, making them difficult to remove. This type of label printing is ideal for products that require a high level of security or privacy, such as clothing or accessories.

In addition to these standard techniques, there are also specialized label printing processes available for specific applications. For example, UV label printing is commonly used for packaging and shipping purposes, as it provides a clear and vibrant label that stands out against the background. Another example is watermarking, which is used to protect intellectual property and prevent counterfeiting.

As with any manufacturing process, label printing in the textile industry faces several challenges that must be addressed to ensure quality and consistency. One of the main challenges is ensuring that the labels meet all necessary regulatory requirements, such as size, weight, and color codes. Additionally, label printing must be done in a way that minimizes waste and maximizes efficiency.

To address these challenges, many textile companies invest in state-of-the-art label printing equipment and employ experienced technicians who specialize in working with different materials and technologies. By doing so, they can ensure that their labels meet all necessary standards and provide a high level of customer satisfaction.

Case Study: Eco-Friendly Label Printing in the Textile Industry

One example of successful label printing in the textile industry is the implementation of eco-friendly labeling on sustainable textiles. Many consumers today are becoming more conscious of their environmental impact when purchasing products, and this trend has led to increased demand for eco-friendly textiles. To meet this demand, textile manufacturers are adopting new label printing technologies that promote sustainability and reduce waste.

For example, one company in the UK has developed a label printing process that uses biodegradable inks and solvents. This process not only reduces the environmental impact of the label printing process but also provides consumers with information about the materials used in the production of the textiles. By using this technology, the company was able to increase sales and build trust with customers who value sustainability.

Another innovative approach is the use of recycled paper for label printing. This approach not only reduces waste but also provides an additional layer of protection for the products being labeled. For example, one company in China has developed a label printing process that uses recycled paper to create labels that are both visually appealing and environmentally friendly.

Conclusion

Label printing is essential in the textile industry for ensuring product identification, differentiation, and compliance with regulations. With advances in technology and increasing consumer demand for sustainable and eco-friendly products, the importance of label printing in the textile industry continues to grow. As manufacturers continue to explore new ways to improve label printing processes, they will undoubtedly find even greater opportunities for innovation and success in the years to come.

随着现代工业的快速发展,纺织厂标签打印的需求日益增长,本文将围绕纺织厂标签打印的主题,通过英文口语化的方式展开讨论,并提供相关的英文案例说明。

纺织厂标签打印的重要性

纺织厂标签打印在提高产品质量、保证产品安全、提高生产效率等方面发挥着重要作用,通过标签打印,可以清晰地标识产品的种类、规格、生产日期等信息,方便工人操作和追溯,标签打印还可以提高产品的美观度和品牌形象,提升消费者对产品的信任度。

纺织厂标签打印的实践操作

材料选择

在纺织厂标签打印中,需要选择合适的材料,常见的材料包括塑料、金属、纸张等,塑料标签轻便、防水、耐腐蚀,适用于各种环境条件;金属标签具有防锈、耐磨、美观等特点,适用于高端产品;纸张标签则具有环保、可回收、成本低等优点。

打印流程

纺织厂标签打印的流程一般包括设计标签图案、准备打印材料、进行打印操作、检查质量等步骤,在设计标签图案时,需要根据产品的特性和需求进行设计,确保标签与产品相匹配,在准备打印材料时,需要确保打印材料的厚度、颜色、光泽等符合要求,在进行打印操作时,需要使用专业的打印机设备进行打印,并确保打印质量,在检查质量时,需要检查打印出来的标签是否清晰、准确、美观。

案例分析

以某纺织厂为例,该厂采用先进的打印机设备进行标签打印,采用了高质量的纸张和塑料材料,在标签设计方面,该厂根据产品的特性和需求进行了精心设计,使得标签与产品相得益彰,在打印操作过程中,该厂严格把控每个环节的质量,确保了打印出来的标签质量,该厂的标签打印效果得到了客户的高度评价。

纺织厂标签打印的注意事项

-

选择合适的材料和设备,确保打印质量。

-

设计合理的标签图案,确保与产品相匹配。

-

严格控制每个环节的质量,确保产品安全和质量。

-

注意环保和可持续发展,选择环保材料和设备。

纺织厂标签打印是现代工业生产中的重要环节,对于提高产品质量、保证产品安全、提高生产效率等方面发挥着重要作用,在实践操作中,需要注意选择合适的材料和设备,设计合理的标签图案和质量要求,严格控制每个环节的质量,还需要注意环保和可持续发展,选择环保材料和设备,推动工业生产向绿色、环保方向发展。

Articles related to the knowledge points of this article:

A Brief Tour of the Binzhou Zoucheng Textile Factory

The Story of the Spinning Silk in Prosperous Pang Shan Linhong Textile Factory

The Story of Hunan Taikang Textile Factory

The 91 Textile Factory Fire:An Accident Report

The Noisy Background of a Textile Factory

Unleashing the Power of Textile Innovations at the 2024 Textile Expo