Calculating the Shrinkage Rate of Textiles:A Comprehensive Guide

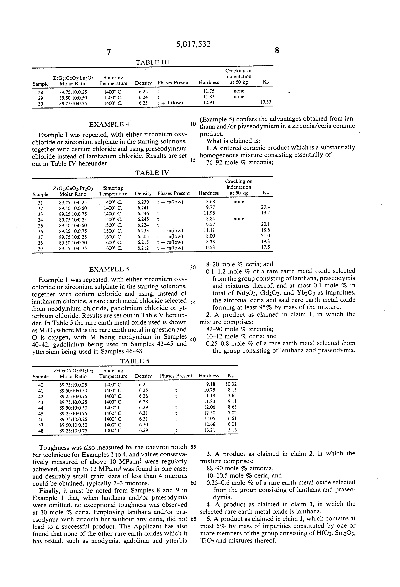

This article provides a comprehensive guide on how to calculate the shrinkage rate of textiles. The shrinkage rate is an important factor in determining the quality and durability of textile products. It refers to the percentage reduction in size after washing or other treatments.,To calculate the shrinkage rate, the following steps should be taken:,1. Collect the required data: This includes the dimensions of the textile before and after washing or other treatments.,2. Determine the weight loss: The weight loss is calculated by subtracting the initial weight from the final weight after washing or other treatments.,3. Calculate the shrinkage rate: The shrinkage rate is calculated by dividing the weight loss by the initial weight. The formula is: shrinkage rate = (weight loss / initial weight) x 100%.,4. Analyze the results: The results of the shrinkage rate calculation can help determine whether the textile has been properly washed or treated. If the shrinkage rate is too high, it may indicate that the textile has not been properly washed or treated.

In the world of textiles, understanding how to calculate shrinkage rate is crucial for manufacturers and designers alike. Shrinkage refers to the reduction in size or volume of a material due to heat treatment, chemical reactions, or other processes. This article aims to provide an in-depth guide on calculating shrinkage rate, including practical examples and case studies to illustrate its application.

Step 1: Understanding Shrinkage

Shrinkage is a natural phenomenon that occurs when a material is subjected to heat, pressure, or chemicals. The degree of shrinkage can vary depending on the type of material, the process used, and other factors. For example, cotton fabrics tend to shrink more than synthetic fabrics like polyester or nylon.

Step 2: Determining the Material

Before calculating shrinkage rate, it's essential to identify the type of material you are dealing with. Different materials have different shrinkage characteristics, so knowing what kind of textile you are working with is crucial. Some common types of textiles include cotton, linen, silk, wool, and polyester.

Step 3: Identifying the Process

Determine the method by which the material will be treated or processed. For example, if the fabric is being washed, dry-cleaned, or ironed, these processes can affect the shrinkage rate. Additionally, the temperature of the process, as well as the duration and frequency of the treatment, can also impact the shrinkage rate.

Step 4: Measuring the Initial Size

Before any treatment, measure the initial size of the fabric. This will serve as the basis for calculating the shrinkage rate. You can use calipers or a ruler to measure the length and width of the fabric.

Step 5: Calculating the Shrinkage Rate

Once you have measured the initial size, you can calculate the shrinkage rate by subtracting the final size from the initial size. To do this, divide the difference in inches by the number of times the fabric was washed or treated. For example, if the fabric was washed three times and each wash reduced the size by 1 inch, the shrinkage rate would be 1/3.

Case Study: Textile Manufacturer's Experience

Let's take a look at a real-life example to illustrate how shrinkage rate can be calculated. Imagine a textile manufacturer who produces high-quality t-shirts using organic cotton. During the production process, they apply a special pre-wash treatment to reduce shrinkage and improve the quality of the fabric.

The manufacturer measures the initial size of the fabric before washing and after washing three times. They then calculate the shrinkage rate by subtracting the final size from the initial size and dividing by the number of washes. In this case, the shrinkage rate would be 1/3, indicating that each wash reduces the size by 1/3.

Conclusion

Calculating shrinkage rate is essential for textile manufacturers and designers to ensure that their products meet customer expectations and meet regulatory requirements. By following the steps outlined above, you can accurately determine the shrinkage rate of your textiles and make informed decisions about processing and packaging. Remember, understanding shrinkage is a critical aspect of textile manufacturing, and it's crucial to stay up-to-date with the latest techniques and methods to achieve optimal results.

纺织品收缩率计算概述

在纺织品的生产与贸易过程中,了解并准确计算纺织品收缩率是非常重要的,本文将详细介绍如何计算纺织品收缩率,并结合实际案例进行说明。

纺织品收缩率的计算方法

定义与基本原理

纺织品收缩率是指纺织品在特定条件下,其尺寸变化与原始尺寸之比,其计算公式通常基于材料的物理性质和纺织工艺。

计算公式举例

(1)根据材料特性计算: 收缩率 = (最终尺寸 - 原尺寸) / 原尺寸 × 100% 最终尺寸为纺织品经过特定工艺处理后的尺寸,原尺寸为纺织品原始尺寸。

(2)实际应用中的表格说明:

| 纺织材料 | 收缩率计算公式示例 | 举例说明 |

|---|---|---|

| 纯棉织物 | 收缩率 = (最终尺寸 - 原尺寸) / 原尺寸 × 100% | 根据不同工艺处理后的尺寸与原始尺寸对比得出 |

| 涤纶织物 | 收缩率 = (收缩系数 × 原尺寸) / 材料厚度 | 根据材料的物理性质和织物厚度计算得出 |

案例分析

(1)案例一:纯棉织物收缩率的计算

假设某纯棉织物经过某种工艺处理后,其最终尺寸比原始尺寸缩小了5%,根据上述计算公式,可以得出该纯棉织物的收缩率为5%。

(2)案例二:涤纶织物收缩率的计算

对于涤纶织物,其收缩率通常受到织物厚度的影响,假设某涤纶织物的厚度为0.5毫米,经过特定工艺处理后,其收缩系数为X%,那么其收缩率可以通过以下公式计算:收缩率 = X% / 材料厚度,在实际应用中,需要根据具体的工艺参数和材料特性进行计算。

纺织品收缩率的注意事项

- 材料选择:在选择纺织品时,应考虑材料的物理性质和织造工艺,以确保其具有适当的收缩率。

- 工艺控制:在纺织过程中,应严格控制工艺参数,以确保纺织品具有合适的收缩率。

- 实际应用中的注意事项:在实际应用中,应结合具体的纺织工艺和材料特性进行计算,以确保结果的准确性。

纺织品收缩率是衡量纺织品性能的重要指标之一,通过正确的计算方法和实际案例分析,可以更好地了解并掌握纺织品收缩率的相关知识,在实际应用中,应结合材料特性、工艺控制等因素进行综合考虑,以确保纺织品的性能和质量。

Articles related to the knowledge points of this article:

A Glimpse into Textiles:A Comprehensive Guide to Portraits of Fabric Exhibits

Exploring the World of Textiles at Pei Countys King Construction Textile Store