A Comprehensive Guide to Fire-resistant Textile Structures

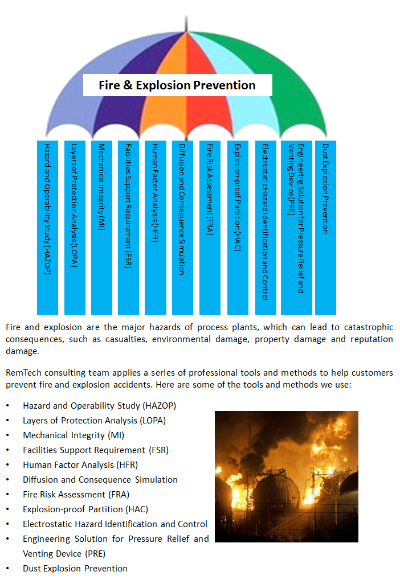

: A Comprehensive Guide to Fire-resistant Textile Structures,This comprehensive guide provides an overview of fire-resistant textile structures, highlighting the importance of these materials in protecting against fire. The guide covers various types of fire-resistant textiles, including non-woven and woven fabrics, as well as their applications in various industries such as construction, manufacturing, and transportation. The guide also discusses the factors that influence the fire-resistant properties of these materials, including fiber type, weave pattern, and construction methods. Additionally, the guide provides tips on how to select and use fire-resistant textiles effectively, including selecting appropriate materials for different applications and implementing proper installation techniques. Overall, this guide is a valuable resource for anyone seeking to understand and implement effective fire-resistant textile structures in their work or personal life.

Introduction: In the realm of textiles, fire safety has become an increasingly important consideration for both consumers and manufacturers alike. The ability to resist flames, burns, and smoke is not only critical in protecting individuals from potential harm but also in preventing extensive damage to property. This guide aims to provide a comprehensive overview of the various components that make up fire-resistant textiles, including their structure, materials, and applications. We will also delve into some real-world examples to illustrate how these principles are put into practice.

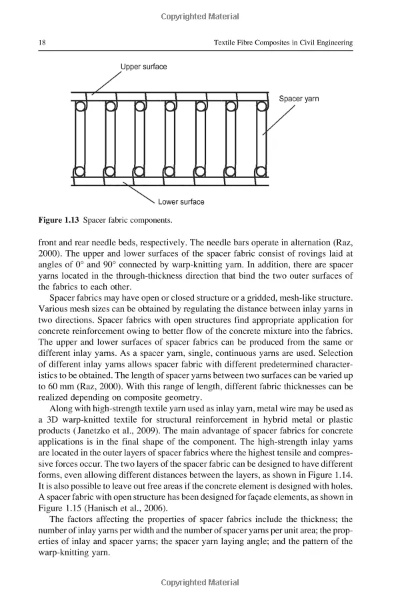

Fabric Structure: Fire-resistant fabrics are designed with specific structures that enhance their resistance to heat and flames. These structures can be classified as either natural or synthetic fibers, with each offering its own set of advantages and disadvantages.

Natural Fibers:

- Wool: Highly thermally resistant, breathable, and flame retardant.

- Cotton: Generally less expensive than wool but still provides good fire resistance.

- Linen: Lightweight and breathable, but may not be as effective at resisting flames.

Synthetic Fibers:

- Polyester: Durable, strong, and relatively easy to manufacture.

- Nylon: Highly durable and resistant to heat and flames.

- Polypropylene: Lightweight, strong, and flame-resistant.

-

Materials: The choice of materials significantly impacts the overall fire resistance of a textile. Common materials include polyurethane (PU), acrylic, and polyester blends.

-

Applications: Fire-resistant textiles find use in a wide range of industries, including construction, apparel, home furnishings, and automotive. They are especially important in high-risk environments where fire safety regulations are stringent.

Case Study: Consider the case of the 2009 Mumbai subway bombings, where the terrorists used a combination of explosives and cloth to create a powerful detonation. The victims were protected by fire-resistant garments made from polyester and nylon blends, which provided significant protection against the intense heat generated by the explosion. These garments not only helped prevent burns but also served as a deterrent against further attacks.

Challenges and Future Trends: While advancements in technology have led to increased fire resistance in textiles, there are still challenges to overcome. For example, developing more sustainable materials that are also fire-resistant is a growing area of research. Additionally, incorporating advanced technologies like nanotechnology could lead to even greater levels of fire protection.

Conclusion: Understanding the structure and materials of fire-resistant textiles is crucial for ensuring the safety of individuals and property. By examining the different types of fibers, materials, and their applications, we can better appreciate the importance of this field and the ongoing efforts being made to improve fire safety measures. As technology continues to advance, we can expect to see even more innovative solutions that will help protect us from the devastating effects of fire.

阻燃纺织品概述

阻燃纺织品是一种特殊类型的纺织品,其具有优异的阻燃性能,能在特定条件下防止火灾的发生,其结构组成主要包括纤维、基材和添加剂三个主要部分。

纤维部分

纤维类型

阻燃纺织品主要采用具有阻燃特性的纤维类型,如聚丙烯(PP)、聚酰胺(PA)、玻璃纤维等,这些纤维具有优异的热稳定性和化学稳定性,能够有效抵抗高温和化学腐蚀。

纤维长度与直径

纤维的长度和直径会影响其燃烧性能和织物结构,较短的纤维直径和较密的织物结构有助于提高阻燃性能,添加剂的使用也会影响纤维的长度和直径,从而影响织物的阻燃性能。

基材部分

基材是阻燃纺织品的主体部分,通常采用高分子材料或复合材料制成,高分子材料具有较高的强度和稳定性,能够提供足够的支撑和保护作用,复合材料则能够提供更好的防火性能和耐久性。

添加剂部分

添加剂是阻燃纺织品的重要组成部分,用于提高其阻燃性能和耐久性,常见的添加剂包括阻燃剂、防火剂、抗氧化剂等,这些添加剂能够与纤维和基材发生化学反应,形成稳定的阻燃结构,从而提高织物的阻燃性能。

以下是一个具体的英文案例说明:

阻燃纺织品结构组成分析

某公司生产的一款阻燃纺织品采用了先进的阻燃技术,其结构组成如下:

- 纤维部分:采用高强度聚丙烯纤维,长度适中,直径均匀,同时添加了特殊的防火剂和抗氧化剂,以提高纤维的阻燃性能和耐久性。

- 基材部分:采用高分子材料制成,具有优异的强度和稳定性,复合了特殊的防火层,以提高整体的防火性能。

- 添加剂部分:添加了高效的阻燃剂,能够与纤维和基材发生化学反应,形成稳定的阻燃结构,同时添加了防潮剂和防紫外线剂,以提高织物的防水性和抗紫外线性能。

表格补充说明

阻燃纺织品结构组成成分表

| 成分名称 | 类型 | 用量(%) | 描述 |

|---|---|---|---|

| 纤维类型 | 聚丙烯、聚酰胺等 | 根据需求确定 | 具有优异的阻燃性能 |

| 高分子材料 | 主体部分 | 根据需求确定 | 提供足够的支撑和保护作用 |

| 防火剂 | 添加剂部分 | 根据需求确定 | 提高纤维的阻燃性能和耐久性 |

| 抗氧化剂 | 添加剂部分 | 根据需求确定 | 提高织物的抗氧化性能 |

| 其他添加剂 | 根据实际需求添加 | 根据实际需求确定 | 提高其他性能指标 |

阻燃纺织品是一种特殊类型的纺织品,其结构组成主要包括纤维、基材和添加剂三个主要部分,该产品采用了先进的阻燃技术,具有优异的阻燃性能和耐久性,在生产过程中,需要严格控制各个成分的比例和用量,以确保产品的质量和性能达到要求。

Articles related to the knowledge points of this article:

Expanding the Canvas of Fashion:The Multi-Stamp Technique in Textiles

杰丽佳纺织品 A Global Brand with a Heart

A Glimpse into the Dynamics of Suzhou Silk and Dyeing Market

The Fabric of Innovation:A Look at Wenzhou Huanhong Textiles

Navigating the New Trends in Xinxiang Textile Fabric Wholesale Market