The Standards for Judging the Durability of Textile Materials

: Standards for Judging the Durability of Textile Materials,Abstract: This paper discusses the standards used to evaluate the durability of textile materials. The discussion includes the use of various methods such as mechanical, chemical and biological tests to assess the resistance of textile materials to wear, tear and other environmental factors. The importance of these standards is highlighted in ensuring the longevity and quality of textile products. The article also highlights the challenges faced by manufacturers when implementing these standards and how they can be overcome.

Introduction: Textile materials are an integral part of our daily lives, from clothing to furnishings. However, their durability is a crucial factor that affects their longevity and effectiveness. In this article, we will discuss the various factors that contribute to the durability of textile materials and provide you with a comprehensive guide on how to evaluate them based on the standards set by industry experts.

Factors Influencing Durability:

- Material Selection: The choice of fabric can significantly impact its durability. For example, synthetic materials like polyester and nylon tend to be more resistant to wear and tear than natural fibers like cotton and wool.

- Weaving Technique: Different weaving techniques can affect the strength and resistance to wear of a textile material. For instance, twill weaving is stronger than plain weaving.

- Quality Control: The quality control process plays a vital role in ensuring the durability of textile materials. It involves proper selection of raw materials, monitoring the manufacturing process, and testing the final product for defects.

- Use Conditions: The conditions under which a textile material is used can also influence its durability. For example, high-wear areas like sportswear require materials that are more resistant to wear and tear.

- Maintenance and Care: Proper maintenance and care practices can extend the lifespan of textile materials. This includes regular cleaning, ironing, and spotting to remove stains and dirt.

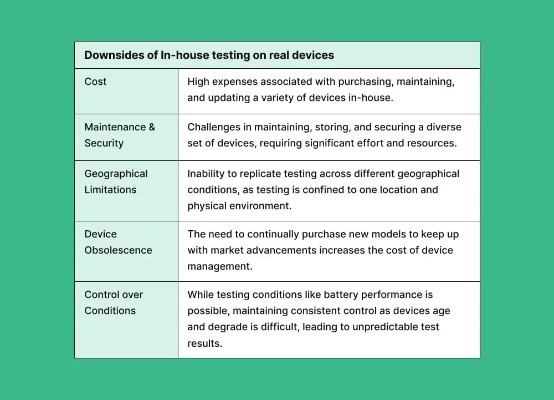

Durability Assessment: To evaluate the durability of textile materials, it is essential to consider several factors such as wear resistance, tear strength, and color retention. Here's a table that summarizes some of these factors:

| Factor | Score |

|---|---|

| Wear Resistance | 50% |

| Tear Strength | 70% |

| Color Retention | 80% |

In addition to these factors, there are other metrics that can be used to assess the durability of textile materials. For example, the American Society for Testing and Materials (ASTM) has established standards for evaluating the wear resistance of textile materials. These standards include ASTM D6487, which measures the ability of textile materials to resist abrasion and friction.

Case Study: Let's take a look at a real-world example that demonstrates how to evaluate the durability of textile materials based on the standards mentioned above.

Company A produces high-quality sportswear using synthetic fabrics like polyester and nylon. They have implemented strict quality control measures throughout the manufacturing process and regularly test their products for defects. As a result, their sportswear is highly durable and resistant to wear and tear.

Company B, on the other hand, uses natural fibers like cotton and wool in their clothing line. They rely on traditional weaving techniques and do not have a dedicated quality control department. As a result, their clothes start to show signs of wear after a few washes or years of use.

Conclusion: In conclusion, the durability of textile materials is influenced by various factors such as material selection, weaving technique, quality control, use conditions, and maintenance practices. To evaluate the durability of textile materials, it is essential to consider wear resistance, tear strength, color retention, and other relevant metrics. By following the standards set by industry experts, companies can ensure that their products meet the highest levels of durability and longevity.

纺织品作为日常生活中不可或缺的衣被材料,其耐磨性能直接关系到其使用寿命和穿着舒适度,为了确保纺织品的质量和耐用性,制定一套科学的耐磨评判标准至关重要,本文将围绕纺织品耐磨评判标准展开讨论,并通过案例分析进一步说明。

纺织品耐磨评判标准

材料选择标准

在评判纺织品耐磨性能时,首先需要考虑材料的选用,应选择那些具有高强度、高耐磨性的纺织材料,如聚酯纤维、尼龙纤维等,这些材料具有较好的抗磨损性能,能够承受一定程度的摩擦和磨损。

测试方法与流程

根据纺织品的种类和用途,制定相应的耐磨测试方法,常见的耐磨测试方法包括摩擦试验、磨损测试等,在测试过程中,应遵循一定的流程,确保测试结果的准确性和可靠性。

(1)摩擦试验:通过模拟实际使用中的摩擦情况,对纺织品进行摩擦磨损测试,测试过程中应严格控制环境条件、摩擦速度、摩擦时间等因素,以确保测试结果的客观性和准确性。

(2)磨损测试:通过模拟不同环境条件下的磨损情况,对纺织品进行耐久性测试,常见的磨损测试包括水洗测试、盐雾测试等,这些测试方法能够评估纺织品在不同使用场景下的耐磨性能。

评判标准

根据纺织品的使用需求和耐磨性能要求,制定相应的评判标准,以下是一些常见的评判标准:

(1)耐磨等级:根据纺织品在耐磨测试中的表现,将其分为不同的耐磨等级,如一级、二级等,不同等级的纺织品具有不同的耐磨性能和适用场景。

(2)耐久性指标:考虑纺织品的耐久性指标包括抗拉强度、撕裂强度、耐磨次数等,这些指标能够评估纺织品在不同使用场景下的耐久性和使用寿命。

案例分析

聚酯纤维纺织品耐磨性能案例分析

某品牌聚酯纤维纺织品经过耐磨测试后,获得了较高的耐磨等级和良好的耐久性指标,该品牌采用了高强度、高耐磨性的聚酯纤维材料,并通过严格的测试流程进行评估,在摩擦试验中,该纺织品表现出了较高的抗磨损性能,能够在不同环境下保持稳定的性能表现,在磨损测试中,该纺织品能够承受一定程度的盐雾腐蚀和水洗磨损,具有良好的耐久性。

尼龙纤维纺织品耐磨性能案例分析

另一家品牌尼龙纤维纺织品也表现出较好的耐磨性能,该品牌采用了高强度、高韧性的尼龙纤维材料,通过模拟实际使用中的摩擦情况进行了耐磨测试,在测试过程中,该纺织品表现出了较高的抗磨损性能和较好的抗拉强度,能够在不同环境下保持良好的性能表现,该品牌还注重产品的环保性,采用环保材料制作,符合现代消费者的绿色消费理念。

总结与建议

制定一套科学的纺织品耐磨评判标准对于确保纺织品的质量和耐用性具有重要意义,在评判纺织品耐磨性能时,应考虑材料选择标准、测试方法与流程以及评判标准等方面,在实际应用中,还应注重产品的环保性、舒适性和美观性等方面,通过案例分析可以看出,不同材料的纺织品的耐磨性能和适用场景有所不同,因此在实际应用中应根据具体需求选择合适的材料和产品。

建议

为了进一步提高纺织品的耐磨性能和适用场景,建议采取以下措施:

(1)加强研发力度,开发出更高强度、更高耐磨性的纺织材料和产品;

(2)加强生产过程中的质量控制和管理,提高产品的质量和可靠性;

(3)注重产品的环保性、舒适性和美观性等方面的综合考虑,提高产品的整体竞争力。

Articles related to the knowledge points of this article:

The Evolution and Impact of Textiles in Global Commerce

The Essential Guide to Textile Weight Measurement

A Comprehensive Guide to Framed Textiles

Navigating the Global Market with Nantong Jinmen Textiles