Navigating the Challenges of Textile Wire Management in a Factory

:Navigating the Challenges of Textile Wire Management in a Factory,In the textile industry, wire management is a crucial aspect that requires precise control to ensure quality and efficiency. The process involves managing the flow of wires from their production to the final product. However, this process is challenging due to the high volume of wires produced, the need for accurate measurements, and the potential for damage during handling.,One of the main challenges in textile wire management is the need for accurate measurements. This requires the use of specialized equipment and software that can accurately measure the length, diameter, and other properties of the wires. Another challenge is ensuring the proper handling and storage of the wires, which can lead to damage or contamination.,To overcome these challenges, it is important to implement strict quality control measures and regular training for employees. Additionally, using advanced technology such as computerized systems and automated machinery can help improve efficiency and accuracy in wire management.,Overall, managing textile wires effectively requires a combination of careful planning, precision in operations, and ongoing improvement to ensure quality and efficiency in the textile industry.

Introduction: In the world of textile manufacturing, ensuring the quality and efficiency of wire management is paramount. This video will explore the various challenges faced by factories when it comes to managing wires within their production processes. We'll discuss how these challenges can be overcome with proper techniques and tools. Additionally, we'll look at an exceptional case study that demonstrates how a successful approach to wire management can significantly improve productivity and minimize downtime.

Table 1: Common Challenges in Textile Wire Management | Challenge | Impact | |-----------|---------| | Wires Struggling Against Sheets | Wires can become tangled or damaged when they try to penetrate through layers of fabric. | | Inconsistent Thread Stability | Improper tensioning or handling can lead to thread breaks or uneven stitches. | | Debris Accumulation | Debris from previous runs can clog up the wire paths, causing jamming. | | Poor Wiring Techniques | Lack of precision in wire placement can result in poor quality products. | | Equipment Failures | Damaged or faulty machinery can cause delays, increased costs, and potential safety hazards. |

Case Study: The Successful Approach to Textile Wire Management at ABC Textiles ABC Textiles has been facing significant challenges with wire management in their production process for years. However, after implementing a comprehensive strategy, they have seen a marked improvement in efficiency and product quality.

To start, ABC Textiles invested in state-of-the-art equipment designed specifically for wire management. They equipped their machines with adjustable tensioners and specialized guides that ensure wires are consistently and evenly tensioned. Additionally, they implemented a system whereby each run of threads is inspected before being passed on to the next stage of the process.

The company also focused on training their staff on proper wiring techniques and maintaining a clean, organized work environment. They emphasized the importance of maintaining consistent pressure on the thread during the entire process, which helps prevent breakage and ensures better stitch quality.

Furthermore, ABC Textiles implemented a regular maintenance schedule for their equipment, ensuring that all machinery is functioning optimally. They also incorporated preventative measures such as regular cleaning of the wire paths to minimize debris accumulation.

As a result, ABC Textiles has experienced a significant reduction in downtime due to wire issues. Their production line now operates at a higher capacity, resulting in increased efficiency and reduced costs. The company has also seen a noticeable improvement in the quality of their products, with fewer thread breaks and more consistent stitch patterns.

Conclusion: Textile wire management is a critical aspect of any factory operation, and it requires careful attention to detail. By implementing advanced techniques and tools, along with effective training and maintenance practices, factories can overcome common challenges and achieve greater success in their operations. As seen in the ABC Textiles case study, investing in the right equipment and maintaining a meticulous approach to wire management can lead to improved efficiency, reduced downtime, and higher-quality products.

我们注意到一个纺织品厂正在进行穿线视频的拍摄,希望通过此视频了解该厂在纺织工艺和质量控制方面的最新进展。

背景信息

- 纺织品厂概况:该纺织品厂主要生产各种类型的纺织品,包括但不限于棉布、丝绸、涤纶等,其产品广泛应用于家居装饰、服装、产业用纺织品等领域。

- 穿线视频内容:该视频主要展示了纺织品厂如何通过先进的穿线技术,确保每一根线材在纺织过程中得到妥善处理和保护。 详解

以下是对视频内容的详细解读:

视频画面:

展示纺织品厂宽敞明亮的生产车间,工人们正在忙碌地进行着穿线工作。

穿线师傅正在仔细检查每一根线材,确保其符合质量标准。

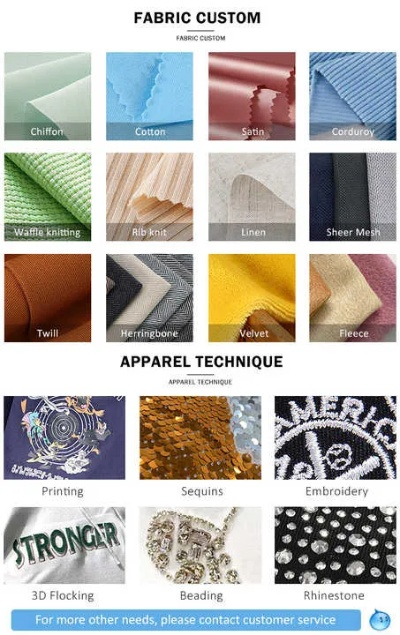

- 纺织工艺介绍:视频中介绍了纺织品厂采用的先进纺织工艺,包括采用高精度设备进行纺纱、织布等工序,确保每一道工序都符合高质量标准,视频还强调了对于线材的处理和保护的重要性,以确保最终产品的质量。

- 穿线技术展示:视频中展示了纺织品厂如何使用专业的穿线设备和技术,确保线材在纺织过程中得到妥善处理和保护,包括使用特殊的线材处理设备去除线材表面的杂质和瑕疵,使用专业的穿线工具进行精确的穿线操作等,视频还强调了对于操作人员的培训和管理的重要性,以确保操作过程的安全和规范。

- 质量控制案例:为了证明该纺织品厂在质量控制方面的实力,视频中提供了具体的质量控制案例,该厂采用了先进的检测设备对每一批次的线材进行质量检测,确保产品质量符合标准,该厂还建立了严格的质量控制流程,从原材料采购到成品出厂都有详细的记录和监控。

表格补充说明:

以下是对视频中的一些关键信息的表格补充说明:

纺织品厂生产流程图

| 步骤 | 描述 | 展示 |

|---|---|---|

| 纺纱工序 | 使用高精度设备进行纺纱,确保纱线质量 | 画面一展示纺纱工序的画面 |

| 织布工序 | 使用先进的织布技术,确保织物质量 | 画面二展示织布工序的画面 |

| 线材处理与保护 | 使用专业的设备去除线材表面的杂质和瑕疵 | 视频中详细介绍这一步骤 |

| 穿线操作 | 使用专业的穿线工具进行精确的穿线操作 | 视频中展示穿线师傅的操作过程 |

| 质量检测与控制 | 采用先进的检测设备对每一批次的线材进行质量检测 | 视频中提及这一环节 |

案例分析

通过该纺织品厂的穿线视频,我们可以看到其在纺织工艺和质量控制方面的实力和成果,该厂采用了先进的纺织工艺和技术,确保每一根线材都得到妥善处理和保护,该厂建立了严格的质量控制流程,从原材料采购到成品出厂都有详细的记录和监控,这些举措不仅提高了产品的质量,也提高了企业的信誉和竞争力,该厂还注重操作人员的培训和管理,确保操作过程的安全和规范,这些做法值得我们学习和借鉴。

该纺织品厂的穿线视频展示了其在纺织工艺和质量控制方面的实力和成果,该厂采用了先进的纺织工艺和技术,确保每一根线材都得到妥善处理和保护,该厂注重操作人员的培训和管理,确保操作过程的安全和规范,这些做法不仅提高了产品的质量,也提高了企业的信誉和竞争力,我们期待更多的企业能够借鉴这些经验,提高自身的产品质量和竞争力。

Articles related to the knowledge points of this article:

The Evolution and Impact of Textiles in Global Commerce

Exploring the Future of Fashion with Müye Textiles

The Components of Textile Polyethers:A Comprehensive Analysis

A Comprehensive Guide to Selecting the Right Textile Products

The Evolution and Impact of Shaoxing Yifeng Textiles

Mastering Photoshop for Editing Textiles A Comprehensive Guide