The Standards for Wet-Processed Textiles:A Comprehensive Guide

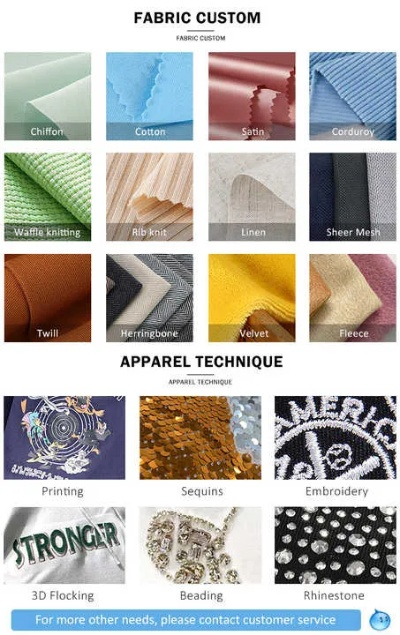

: A Comprehensive Guide to the Standards for Wet-Processed Textiles,Abstract:,This comprehensive guide aims to provide a detailed overview of the standards that govern wet-processed textiles, including their classification, testing methods, and compliance requirements. The guide covers various aspects such as material selection, processing methods, quality control, and environmental considerations. It provides essential information for manufacturers, distributors, and consumers to ensure that their products meet industry standards and comply with regulations.,Key Points:,1. Introduction to wet-processed textiles: This guide provides an introduction to the different types of wet-processed textiles, including cotton, polyester, and nylon.,2. Classification of wet-processed textiles: The guide explains the different classifications of wet-processed textiles, such as plain weave, twill weave, and knitted fabrics.,3. Testing methods for wet-processed textiles: The guide discusses the testing methods used to evaluate the quality and performance of wet-processed textiles, including tensile strength, tear strength, and water absorption.,4. Compliance requirements for wet-processed textiles: The guide outlines the compliance requirements for wet-processed textiles, including labeling, certification, and environmental impact assessment.,5. Conclusion: The guide concludes by providing tips for manufacturers and distributors on how to maintain compliance with the standards for wet-processed textiles and ensure the safe and sustainable production of these products.

In the world of textiles, wet processing is a critical step that transforms raw materials into finished products. This process involves treating fabrics with chemicals to enhance their properties, such as colorfastness, strength, and durability. To ensure quality and consistency in wet-processed textiles, there are strict standards that must be adhered to. In this guide, we will explore the key aspects of wet-processed textile standards, including the use of specific chemicals, temperature control, and testing methods. By following these guidelines, you can produce high-quality textiles that meet industry standards.

Wet-processed textiles are characterized by their ability to withstand various treatments, making them ideal for use in outdoor applications, such as clothing, carpets, and upholstery. These textiles undergo a series of chemical processes, including dyeing, printing, and finishing, which can affect their performance and appearance. Therefore, it is essential to follow specific guidelines to ensure that the final product meets the desired standards.

One of the most important aspects of wet-processed textiles is the choice of chemicals used during the treatment process. Different textiles require different types of chemicals to achieve optimal results. For example, cotton fabrics may require chlorine bleaching agents to remove dirt and stains, while polyester fabrics may need oxidizing agents to improve their resistance to UV rays. It is crucial to select appropriate chemicals based on the type of textile and the intended application.

Another critical factor in wet-processed textiles is temperature control. The temperature at which the textiles are treated affects their quality and performance. High temperatures can cause damage to the fibers and reduce their strength, while low temperatures can slow down the chemical reactions and result in incomplete treatment. Therefore, it is essential to monitor the temperature during the treatment process and adjust it accordingly.

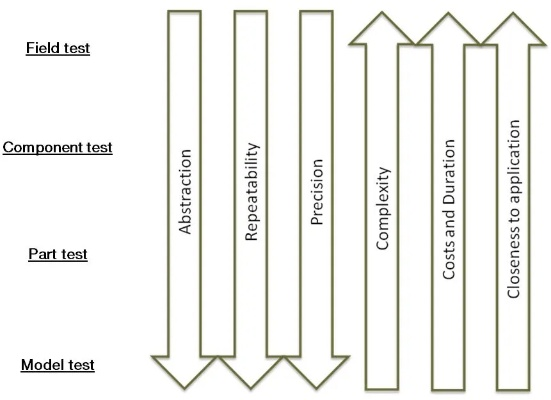

Testing is an essential part of ensuring the quality of wet-processed textiles. Testing methods include visual inspection, colorfastness tests, and mechanical testing. Visual inspection involves examining the surface of the textile for any defects or irregularities. Colorfastness tests measure how well the textile retains its color after exposure to light and chemicals. Mechanical testing evaluates the strength and resilience of the textile under various conditions.

To illustrate these points, let's consider a case study involving a textile manufacturer who produces outdoor wear garments using polyester fabrics. The manufacturer follows the standard wet-processed textile guidelines, selecting appropriate chemicals and monitoring temperature during the treatment process. They also conduct regular testing to ensure that the final product meets all industry standards. As a result, their garments have excellent colorfastness and durability, meeting customer expectations and gaining a positive reputation in the market.

In conclusion, wet-processed textiles are critical components of our daily lives. By adhering to specific guidelines, such as selecting appropriate chemicals and temperature control, testing methods, and following industry standards, manufacturers can produce high-quality textiles that meet consumer needs. By following these guidelines, you can produce high-quality textiles that meet industry standards.

随着纺织行业的快速发展,纺织品的质量和性能要求不断提高,湿磨作为纺织品加工的重要环节,其标准制定对于提高产品质量、保障消费者权益具有重要意义,本篇文章将围绕纺织品湿磨标准展开讨论,并通过案例分析进一步说明。

纺织品湿磨标准概述

- 定义与分类

纺织品湿磨标准是指对纺织品在湿态下进行加工、整理和测试的一系列规定和准则,根据不同的工艺流程和应用领域,湿磨标准可分为不同的类型,如针对不同材质的纺织面料、纱线等。

纺织品湿磨标准主要包括以下几个方面:

- 原料选择与检验:明确原料的种类、质量要求。

- 设备与工艺:规定湿磨设备的类型、参数、操作流程。

- 测试方法:明确湿磨后的纺织品性能测试标准。

- 安全与环保:强调湿磨过程中的安全措施和环保要求。

纺织品湿磨标准案例分析

某知名品牌纺织品湿磨标准实施情况

某知名品牌在纺织品生产过程中,严格按照湿磨标准进行操作,其设备选型合理,工艺流程规范,测试方法科学,在原料选择上,严格把关,确保原料质量符合要求,在设备操作过程中,严格控制温度、湿度等参数,确保加工过程中的稳定性和一致性,在测试环节,采用了多种性能测试方法,全面评估纺织品的质量和性能。

新型纺织材料湿磨技术应用案例

近年来,新型纺织材料的应用越来越广泛,某新型纺织材料生产企业采用了先进的湿磨技术,实现了高效、环保的加工过程,该企业采用了高效节能的湿磨设备,优化了工艺流程,提高了生产效率,该企业注重环保措施的实施,严格控制废水、废气等排放标准,实现了生产过程的绿色化。

纺织品湿磨标准补充说明

原料选择与检验标准补充说明

在原料选择与检验方面,应注重原料的种类、质量、产地等信息,应建立严格的检验流程,确保原料符合相关标准和要求,对于特殊材质的纺织面料,还应进行特殊处理和测试,以确保其性能和质量满足要求。

设备与工艺参数补充说明

在设备与工艺参数方面,应根据不同的工艺流程和应用领域,制定相应的参数范围和调整方法,应注重设备的维护和保养,确保其稳定性和可靠性,在工艺参数调整过程中,应充分考虑生产效率、产品质量、能耗等因素,进行科学合理的调整。

测试方法补充说明

在测试方法方面,应采用先进的测试仪器和方法,确保测试结果的准确性和可靠性,应注重测试结果的解读和应用,为生产过程提供科学依据,还应定期对测试方法进行更新和完善,以适应纺织行业发展的新要求和新趋势。

纺织品湿磨标准是保障纺织品质量、提高产品质量的重要手段,通过制定和完善纺织品湿磨标准,可以规范纺织品的加工、整理和测试过程,提高产品质量和性能,采用先进的湿磨技术和设备,可以实现高效、环保的加工过程,促进纺织行业的绿色发展。

Articles related to the knowledge points of this article:

The Fabric of Innovation:An Extensive Analysis of Changshu Junce Textiles

Mastering Photoshop for Editing Textiles A Comprehensive Guide

Exploring Wooden Silk:An Overview of the Fabrics and their Impact on Fashion

Strategies for the Implementation of Medical Textiles:A Comprehensive Guide

The 2022 Textile Show:A Global Tapestry of Innovation and Sustainability

Blue Dream Textiles:A Journey Through Quality and Innovation