纺织品仓库资质要求与案例分析

This paper focuses on the qualification requirements for textile warehouses and provides a case study analysis. The qualification requirements include but are not limited to: having a well-equipped storage facility, maintaining high standards of cleanliness and hygiene, implementing effective inventory management systems, and ensuring compliance with relevant laws and regulations. The case study analyzes the experiences of one specific textile warehouse in China, highlighting the challenges faced by the company during its development and how it overcame them through effective management strategies. The findings suggest that a combination of strong infrastructure, stringent quality control measures, and ongoing regulatory compliance can help textile warehouses achieve success and maintain their competitive edge.

Introduction: In the competitive world of textiles, having a well-established and efficient warehouse is crucial for maintaining quality, reducing costs, and meeting customer expectations. This article will explore the key requirements for obtaining textile warehouse certifications and provide insights into successful implementation of these standards through a case study.

Key Requirements for Textile Warehouse Certifications:

-

Quality Control Systems: Companies must have robust quality control systems in place to ensure that the products stored in their warehouse meet industry standards. These systems should include regular inspections, quality audits, and corrective actions when necessary.

-

Storage and Handling Procedures: The warehouse must have standardized storage and handling procedures to prevent damage to textiles during transit and storage. This includes temperature regulation, humidity control, and proper packaging to protect fragile items.

-

Logistics Management: Companies must have effective logistics management systems to ensure timely delivery of products to customers. This includes inventory management, warehousing optimization, and transportation planning.

-

Environmental Sustainability Practices: In today's climate, companies must prioritize environmental sustainability practices. This includes using energy-efficient lighting, minimizing waste, and implementing recycling programs.

-

Emergency Response Plans: Companies must have emergency response plans in place to handle any unforeseen events that may occur during storage or delivery. This includes fire prevention measures, spill response protocols, and emergency evacuation procedures.

-

Employee Training and Development: Companies must invest in employee training and development to ensure that their staff are well-equipped to handle the challenges of textile warehouse operations. This includes training on safety protocols, quality control techniques, and best practices for managing inventory.

Case Study: XYZ Textiles has been operating a textile warehouse for over a decade and has recently undergone a major upgrade to enhance its warehouse operations. The company has implemented several new certifications in recent years, including the Global Quality Assurance (GQA) Standards and the Green Manufacturing Certification.

The GQA Standards require companies to implement a comprehensive quality control system that includes regular inspections, quality audits, and corrective actions. XYZ Textiles has established a dedicated Quality Control Department responsible for overseeing the implementation of these standards. The company has also invested in advanced equipment such as automated sorting machines and barcode scanners to improve accuracy and efficiency in inventory management.

The Green Manufacturing Certification requires companies to demonstrate commitment to environmental sustainability practices. XYZ Textiles has implemented measures such as energy-efficient lighting, water conservation systems, and recycling programs to reduce its environmental impact. The company has also partnered with local charities to support sustainable initiatives in the community.

Conclusion: Having a well-established and efficient textile warehouse is essential for any company looking to succeed in the competitive market. By following the key requirements for textile warehouse certifications and investing in employee training and development, companies can ensure that they are providing high-quality products to their customers while minimizing costs and minimizing environmental impact.

纺织品仓库资质概述

纺织品仓库作为企业物资储备的重要场所,对于其资质要求至关重要,本文将围绕纺织品仓库资质展开讨论,包括其重要性、必备条件以及相关案例分析。

纺织品仓库资质的重要性

纺织品仓库是企业物资供应链中的重要环节,其资质直接关系到物资的存储、保管和运输质量,一个合格的纺织品仓库需要具备专业的技术和管理能力,以确保物资的存储安全、有效和及时,良好的仓库资质也是企业信誉和形象的重要体现。

纺织品仓库必备资质条件

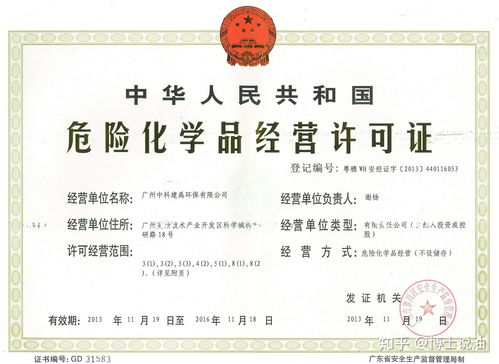

- 资质类型:纺织品仓库通常需要具备营业执照、税务登记证、组织机构代码证等基本资质,根据不同行业和地区的要求,还需要具备相关的行业资质和安全认证。

- 技术能力:纺织品仓库需要具备专业的技术和管理能力,包括但不限于仓储管理、物流配送、安全防护等方面的知识和技能,还需要建立完善的管理体系,确保仓库运营的规范性和高效性。

- 人员资质:纺织品仓库需要配备专业的仓储人员和安全管理人员,他们需要具备相关的专业知识和技能,以及良好的职业道德和安全意识。

相关案例分析

以某大型纺织品仓库为例,其资质情况如下:

- 资质情况:该纺织品仓库拥有营业执照、税务登记证、组织机构代码证等基本资质,同时还具备相关的行业资质和安全认证,该仓库还建立了完善的管理体系,确保物资的存储安全、有效和及时。

- 技术能力:该仓库采用了先进的仓储管理系统和物流配送技术,建立了高效、规范的仓储管理体系,该仓库还配备了专业的仓储人员和安全管理人员,他们具备专业的技术和管理能力,能够确保物资的存储质量和安全性。

- 案例分析:该纺织品仓库在实际运营中表现优异,能够确保物资的存储安全、有效和及时,该仓库还得到了客户的高度认可和好评,这表明,一个合格的纺织品仓库需要具备专业的技术和管理能力,以及良好的运营和服务质量。

提升纺织品仓库资质的措施

为了提升纺织品仓库的资质水平,企业可以采取以下措施:

- 加强培训和教育:企业应该定期对仓储人员和安全管理人员进行培训和教育,提高他们的专业知识和技能水平,企业还可以邀请专家进行讲座和指导,提高他们的管理水平和技术能力。

- 引入先进技术和管理系统:企业应该引入先进的仓储管理系统和物流配送技术,提高物资存储的安全性和效率性,企业还应该建立完善的管理体系,确保仓库运营的规范性和高效性。

- 加强与行业协会的合作:企业可以加强与行业协会的合作,了解行业最新的标准和要求,提高自身的专业水平和竞争力。

纺织品仓库是企业物资供应链中的重要环节,其资质对于物资的存储、保管和运输质量有着至关重要的影响,企业应该重视纺织品仓库的资质问题,采取有效的措施提升其资质水平,企业还应该加强与行业协会的合作,了解行业最新的标准和要求,提高自身的专业水平和竞争力。

Articles related to the knowledge points of this article:

Top Ten Textile Brands in the Rankings

Custom-Made Textiles in Shandong Expanding Horizons with Innovation

The Dynamics of Nan Yixin Textile Industry:A Comprehensive Analysis