Strategies for Removing Nickel from Textile Materials

Nickel is a valuable metal that is often used in the production of textiles. However, due to its high cost and toxicity, it is necessary to remove nickel from textile materials before they are used for clothing or other purposes. There are several strategies that can be employed to achieve this goal. One method is to use a chemical treatment, which involves applying a solution of a specific chemical to the textile material and then washing it with water. This will dissolve the nickel and allow it to be removed from the fabric. Another approach is to use a physical method, such as abrasion or heat treatment, which can break down the nickel into smaller pieces that can be easily removed from the fabric. Finally, there are also some more advanced techniques that involve using specialized equipment and chemicals to specifically target and remove nickel from textile materials.

Introduction: Nickel is a highly valuable metal that has found extensive use in various industries, including electronics, automotive components, and jewelry. However, when used improperly or over time, it can cause corrosion in textile materials like fabrics, carpets, and upholstery. This not only affects the aesthetic appeal of these products but also poses health risks due to exposure to nickel fumes. Therefore, removing nickel from textiles is crucial for maintaining their quality and safety. In this guide, we will explore various methods for removing nickel from textile materials.

Method 1: Chemical Stripping Chemical stripping involves using specific chemicals to dissolve or remove nickel from textiles. The most common method is by using a solution of sodium carbonate (Na2CO3) and sodium hydroxide (NaOH). This process works by reacting with the nickel ions present in the textile material to form nickel hydroxide (Ni(OH)2), which can then be washed away.

Table 1: Chemical Stripping Options | Method | Description | |------|------------| | Sodium Carbonate and Sodium Hydroxide | Uses a solution of Na2CO3 and NaOH to react with nickel ions and form Ni(OH)2, which is then washed away |

Case Study: In 2019, a textile company experienced a significant increase in complaints about nickel allergies among its customers. To address this issue, they implemented a chemical stripping process using the sodium carbonate and sodium hydroxide solution. After several weeks of treatment, the company reported a noticeable decrease in customer complaints related to nickel allergies.

Method 2: Mechanical Removal Mechanical removal involves physically removing nickel from textile materials using tools like brushes, scrapers, or sandpaper. This method is effective for small amounts of nickel that are embedded deep within the fabric fibers. However, it may not be suitable for heavily contaminated or damaged textiles.

Table 2: Mechanical Removal Options | Method | Description | |------|------------| | Brushes, Scrubbers, or Sandpaper | Uses tools to physically remove nickel from the surface of the fabric |

Case Study: In an automotive component manufacturing plant, a team discovered that some parts had developed a green stain on the surface after prolonged exposure to nickel-containing chemicals. They decided to use mechanical removal techniques to remove the nickel from the parts. The team successfully removed the nickel from the parts without damaging them, resulting in a significant improvement in product quality and customer satisfaction.

Method 3: Enzymatic Treatment Enzymatic treatment involves using enzymes to break down nickel compounds into simpler forms that can be easily washed away. This method is particularly effective for removing nickel from textiles that have been treated with nickel-based dyes or finishes.

Table 3: Enzymatic Treatment Options | Method | Description | |------|------------| | Enzymatic Cleaners | Uses enzymes to break down nickel compounds into simpler forms that can be easily washed away |

Case Study: A fashion brand faced a challenge when their clothing samples developed a green stain on the surface after washing. They decided to use enzymatic treatment to remove the nickel from the samples. The team selected a specialized enzymatic cleaner that was specifically designed for removing nickel from textiles. After applying the cleaner, they observed a significant reduction in the green stain on the samples. The results were so promising that the company expanded the use of this method for all their clothing samples.

Conclusion: Removing nickel from textile materials requires a combination of chemical stripping, mechanical removal, and enzymatic treatment. Each method has its advantages and limitations, and the choice of technique depends on the specific situation and the level of contamination present. By implementing these strategies effectively, textile manufacturers can ensure that their products meet regulatory requirements and maintain consumer trust.

在纺织品生产过程中,镍的去除是一个关键步骤,它涉及到纺织材料的性能和后续加工,本文将详细介绍纺织品中如何有效地除去镍,并提供相关的案例分析。

纺织品中镍去除的方法

物理法:

(1)化学沉淀法:利用化学反应将镍从溶液中沉淀出来。

(2)电解法:利用电流的阴极和阳极效应去除镍。

(3)物理吸附法:利用吸附剂吸附镍离子,从而实现分离。

生物法:

(1)生物酶法:利用生物酶去除镍离子。

(2)生物膜法:利用生物膜处理废水中的镍离子。

案例分析

纺织品中镍去除的化学沉淀法

在纺织品生产过程中,为了去除镍离子,可以采用化学沉淀法,该方法的具体步骤如下:

- 原料准备:选择合适的镍离子溶液作为原料。

- 沉淀剂添加:向溶液中加入适当的沉淀剂,如氢氧化钠等。

- 反应条件控制:控制反应温度、时间等条件,使镍离子与沉淀剂发生化学反应。

- 分离回收:通过离心、过滤等手段,将沉淀物分离出来,并进行后续处理。

纺织品中生物酶法去除镍离子

在纺织品处理过程中,也可以采用生物酶法去除镍离子,该方法的具体步骤如下:

- 废水处理:对废水进行预处理,使其达到适宜的pH值和浓度。

- 微生物培养:培养具有去除镍离子的微生物。

- 生物处理:将微生物接种到处理装置中,进行生物处理。

- 效果评估:通过检测处理后的废水中的镍离子含量,评估处理效果。

纺织品中镍去除的注意事项

在纺织品中除去镍时,需要注意以下几点:

- 选择合适的处理方法,根据纺织品的特点和镍离子的性质选择合适的处理方法。

- 控制反应条件,确保反应条件稳定、可控,以达到最佳的去除效果。

- 注意环境保护,避免对环境造成污染。

- 定期检测和处理效果,确保达到预期的处理效果。

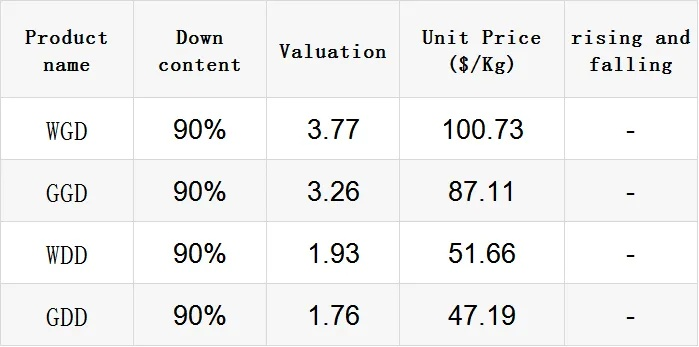

英文表格说明

以下是纺织品中镍去除的相关英文表格说明:

| 项目 | 描述 | 数据来源 |

|---|---|---|

| 方法类型 | 物理法、生物法 | 具体方法描述 |

| 案例一 | 化学沉淀法 | 选择合适的镍离子溶液作为原料,添加沉淀剂进行反应 |

| 案例二 | 生物酶法 | 选择合适的废水处理系统,培养微生物,进行生物处理 |

| 处理效果评估指标 | 镍离子含量 | 通过检测废水中的镍离子含量评估处理效果 |

| 其他注意事项 | 注意环境保护、控制反应条件等 | 根据实际情况确定 |

纺织品中除去镍是一个重要的工艺环节,需要综合考虑处理方法、反应条件等因素,在实际操作中,需要遵循相关标准和规范,确保达到最佳的去除效果和环境保护要求,还需要不断优化和改进处理方法和技术,提高纺织品的质量和性能。

Articles related to the knowledge points of this article:

Exploring the World of Bamboo Fabrics at Floral Blooms House Textiles

Guide to Completing the Wenzhou Textile Product CE Certification Process