The Fabric of Innovation:Unraveling the Science Behind Textiles

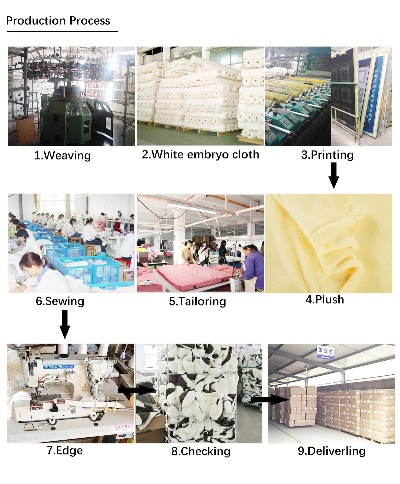

"The Fabric of Innovation: Unraveling the Science Behind Textiles" is a fascinating exploration into the complex science behind the creation and functioning of textiles. This article delves into the various processes involved in the manufacturing of textiles, from the selection of raw materials to the final product's design and application. The author emphasizes the importance of understanding these processes in order to appreciate the beauty and functionality of textiles.,One of the key aspects of this article is its emphasis on the role of science in driving innovation in the textile industry. By examining the latest advancements in technology, such as machine learning and artificial intelligence, the author demonstrates how these tools can be used to improve the efficiency and accuracy of textile production. Additionally, the article explores the potential applications of nanotechnology in textiles, highlighting its ability to enhance durability and sustainability.,Overall, "The Fabric of Innovation: Unraveling the Science Behind Textiles" is an informative and thought-provoking read that provides readers with a deeper understanding of the science behind the creation of textiles. Whether you are a textile designer, manufacturer, or simply interested in the field, this article will provide valuable insights into the exciting world of textile science.

Introduction: In the realm of fashion and function, textiles are the fabric of our lives. From the softness of a cozy blanket to the durability of a military uniform, textiles play an integral role in shaping our environment and enhancing our daily experiences. This talk will explore the intricate science behind these materials, from their structure to their performance, and how they have evolved over time to meet the needs of modern society.

Textile Structure: The structure of a textile is often referred to as its "fabric," which refers to the interlacing of threads that create the material's surface. The structure of a textile can be classified into three main categories: woven, knitted, and nonwoven.

Woven: Woven textiles are created by interlacing individual threads in a grid pattern. The strength and durability of woven fabrics depend on the number of threads per inch (TPI) and the density of the weave pattern. For example, a high-tpi, high-density twill weave would be stronger than a lower-tpi, low-density plain weave.

Knitted: Knitted textiles are created by looping individual threads together to form a continuous chain. The strength and durability of knitted fabrics depend on the number of loops per inch (LPI) and the type of yarn used. For instance, a medium-weight cotton yarn with a LPI of 100 would produce a knitted fabric that is more durable than a lighter cotton yarn with a lower LPI.

Nonwoven: Nonwoven textiles are created by extruding fibers through a die and then bonding them together in a random pattern. Nonwoven fabrics are often used for absorbent materials such as diapers and wipes due to their ability to hold large amounts of liquid without leaking.

Performance: Once the structure of a textile is established, it must perform its intended function. Performance can be measured in terms of various properties, including strength, elasticity, moisture absorption, and breathability.

Strength: The strength of a textile is determined by its tensile strength, which is the force required to break a sample of the material. High-strength textiles are ideal for applications where weight and durability are critical, such as military uniforms and industrial machinery components.

Elasticity: Elasticity refers to the ability of a textile to return to its original shape after being stretched. The higher the elasticity, the more stretchable the textile is. Sportswear and undergarments often require high elasticity to provide comfort and flexibility.

Moisture Absorption: Moisture absorption refers to the amount of water that a textile can hold before it starts to wick away. Moisture absorption is important for absorbent materials like diapers and sanitary towels, which need to quickly absorb and release moisture without leaving behind any residue.

Breathability: Breathability refers to the ability of a textile to allow air to pass through while preventing the passage of liquid. Breathable textiles are ideal for use in outdoor clothing, sportswear, and other applications where breathability is crucial for comfort and functionality.

Case Study: One example of a textile that combines strength, elasticity, and breathability is the athletic wear industry. Nike's Air Max shoes incorporate a high-stretch upper made from a blend of polyester and elastane, which provides excellent flexibility and breathability while also offering superior cushioning and support for running and other activities. These shoes are designed to be lightweight, durable, and comfortable, making them ideal for athletes who demand maximum performance and comfort.

Conclusion: The textile industry is constantly evolving, driven by advancements in technology and new materials. As we continue to push the boundaries of what is possible with textiles, we can expect to see even more innovative designs that cater to the needs of today's society. Whether it's creating eco-friendly materials or developing biodegradable textiles, the future of textiles is bright, and we can look forward to seeing many exciting developments in this field.

纺织品结构概述

纺织品是日常生活中不可或缺的组成部分,其结构与性能直接关系到产品的使用体验和耐用性,本篇将围绕纺织品结构与性能的主题展开讨论,通过英文案例说明来进一步阐述。

纺织品结构要素

纤维类型

纺织品主要由纤维制成,纤维的类型和特性直接决定了其结构与性能,常见的纤维类型包括天然纤维和合成纤维,天然纤维如棉、麻等具有天然的吸湿性、透气性和柔软性,而合成纤维则具有更高的强度和耐用性。

织物组织结构

织物组织结构是决定纺织品外观和性能的关键因素,常见的织物组织结构包括平纹、斜纹、网格等,平纹织物结构简单,透气性好,适合制作夏季衣物;斜纹织物则具有更好的抗皱性和耐磨性,适合制作运动服装和户外用品。

纺织品性能分析

强度与耐磨性

纺织品在强度和耐磨性方面表现优异,能够承受日常使用中的各种压力和摩擦,合成纤维具有较高的强度和耐磨性,能够经受住长时间的使用和洗涤。

吸湿性与透气性

吸湿性是纺织品的重要性能之一,能够调节衣物内部湿度,使穿着更加舒适,透气性则是纺织品保持干爽的关键因素,能够使穿着者感觉更加清爽,在纺织品中,可以通过添加吸湿剂或采用特殊的织造工艺来提高吸湿性和透气性。

案例分析:纺织品结构与性能的具体应用

天然纤维纺织品的应用

以天然纤维制成的纺织品如棉质衬衫为例,其结构简单、透气性好,适合夏季穿着,棉质纺织品还具有吸湿性强、不易产生静电等优点,使得穿着更加舒适。

合成纤维纺织品的应用

合成纤维纺织品在各种领域都有广泛应用,如运动服装、户外用品等,采用特殊工艺和材料制成的合成纤维纺织品具有高强度、耐磨性好等特点,能够经受住长时间的使用和洗涤,一些新型的合成纤维还具有环保、可降解等优点,符合现代消费者的需求。

纺织品结构与性能是决定产品使用体验和耐用性的关键因素,在纺织品的生产过程中,需要注重纤维类型、织物组织结构的选择和优化,以及提高纺织品的强度、吸湿性和透气性等性能,通过案例分析可以看出,纺织品结构与性能的应用范围非常广泛,不仅可以应用于日常穿着的各类纺织品中,还可以应用于运动服装、户外用品等领域。

Articles related to the knowledge points of this article:

The Essential Guide to Textile Weight Measurement

Textile Order Filing Template for Business Operations

The Ultimate Guide to Choosing the Best Materials for Your Fashion Needs

The Fabric of Innovation:An Insight into Kashka Textiles

A Journey into the World of Fabrics with Laughing Leaf Textiles