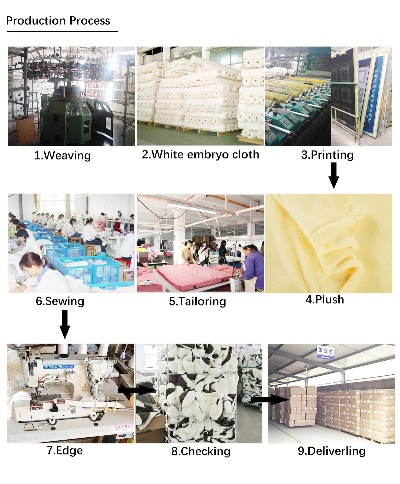

Understanding and Complying with Textile Dyeing and Sizing Processes

The textile dyeing and sizing processes are crucial in the production of textile products. This paper aims to explore the understanding and compliance with these processes. Firstly, it is important to understand the basic principles and techniques involved in the dyeing and sizing processes. This includes knowledge of the different types of dyes used, their properties, and how they interact with the fabric. Additionally, it is essential to understand the factors that affect the quality of the dyed and sized fabric, such as temperature, pH, and time.,To comply with these processes, it is necessary to follow established standards and guidelines. This includes using appropriate dyes and sizing agents, ensuring proper mixing and application, and monitoring the process for any deviations from the desired results. It is also important to regularly inspect the finished product for defects or irregularities, which may indicate an issue with the dyeing or sizing process.,In conclusion, understanding and complying with the textile dyeing and sizing processes is critical for producing high-quality textile products. By following established standards and guidelines, and regularly inspecting the finished product, businesses can ensure that their products meet the needs and expectations of their customers.

In the world of textiles, color is often the most crucial element that sets one product apart from another. The dyeing and sizing processes are essential to achieving the desired color intensity, uniformity, and durability in fabrics. In this article, we will delve into the intricacies of these processes, their significance, and how to ensure compliance with industry standards.

At the heart of textile dyeing lies the process of applying colorants to fabrics. This can be achieved through various methods, including direct dyeing, reactive dyeing, and printing. Direct dyeing involves mixing a dye with a solution of cellulose fibers and allowing the dye to penetrate the fabric. Reactive dyeing, on the other hand, involves reacting a dye with a chemical that bonds with the fiber. Printing involves transferring a design onto the fabric using a printing method such as screen printing or pad printing.

Once the dye has been applied, it must be set to ensure that the color is permanently fixed. This is done through a process called sizing. Sizing involves treating the fabric with a solution that hardens the fibers and prevents them from shrinking or warping. This process is critical for maintaining the integrity of the fabric and ensuring that it meets quality standards.

To comply with industry standards, it is essential to understand the specific requirements for each dyeing and sizing process. For example, some industries may require that fabrics be tested for specific levels of colorfastness, washability, and shrinkage. These tests help manufacturers ensure that their products meet the needs of consumers and regulatory agencies.

One common example of a textile dyeing and sizing process is the use of acid dyes for cotton fabrics. Here, the dye is first treated with an acid solution to break down any natural pigments on the fibers. This allows the dye to penetrate more easily. Once the dye has been applied, it is then set by treating the fabric with a solution of sodium hydroxide (a base) to neutralize the acid and harden the fibers.

Another example is the use of reactive dyes for polyester fabrics. In this process, the dye is first mixed with a solution of acetic anhydride and water. This creates a reaction between the dye and the polyester fibers, which results in a permanent fixation of the color. After the dye has been applied, the fabric is treated with a solution of sodium hydroxide to set the color.

When it comes to sizing, there are several different methods that can be used depending on the type of fabric and the desired outcome. One common method is the use of cationic sizing agents, which help to create a bond between the fibers and the sizing agent. Another method is using a combination of cationic and anionic sizing agents, which helps to achieve better coverage and adhesion to the fabric.

To ensure compliance with industry standards, it is important to follow specific guidelines when working with dyes and sizing agents. For example, many industries have strict regulations regarding the amount of dye and sizing agent that can be used in a particular product. It is also important to test finished fabrics for specific properties, such as colorfastness and shrinkage, to ensure that they meet consumer expectations and regulatory standards.

In conclusion, understanding and complying with textile dyeing and sizing processes is critical for the success of any textile manufacturer. By following industry standards and testing finished products for specific properties, manufacturers can ensure that their products meet consumer expectations and regulatory requirements. As technology continues to advance, it is likely that new methods and materials will emerge, but the fundamental principles of dyeing and sizing remain unchanged.

纺织品染色跟单概述

在纺织品行业中,染色是一项至关重要的工艺环节,它不仅影响着纺织品的外观和质感,还关系到产品的市场竞争力,本篇将围绕纺织品染色跟单的主题,从多个方面进行详细阐述。

纺织品染色工艺流程

- 材料准备:根据客户的需求和产品特性,选择合适的染料和染色工艺。

- 样品测试:在染色前进行样品测试,确保染料的颜色、牢度等符合客户要求。

- 染色操作:在专业染料处理车间进行染色,确保染料均匀分布、染色效果达到预期。

- 质量检测:对染色后的纺织品进行质量检测,确保符合相关标准和客户要求。

案例分析

以某知名纺织品品牌为例,其纺织品染色跟单过程如下:

- 材料选择:根据市场需求和产品特性,选择高品质的染料和染色工艺。

- 样品测试:该品牌在染色前进行了严格的样品测试,确保染料的颜色、牢度等符合客户要求,为了确保染色效果的真实性和可靠性,还邀请了第三方检测机构进行质量检测。

- 染色操作:该品牌采用了先进的染色技术,确保染料均匀分布、染色效果达到预期,在染色过程中,严格控制温度、湿度等参数,确保染色的稳定性和持久性,该品牌还注重环保和可持续性,采用环保染料和绿色染整工艺。

- 客户反馈:经过染色后的纺织品经过严格的质量检测后,得到了客户的高度认可和好评,客户反馈显示,该品牌的纺织品颜色鲜艳、质地柔软、手感舒适,符合客户对高品质纺织品的期望。

纺织品染色跟单注意事项

- 选择合适的染料和染色工艺,确保染料的颜色、牢度等符合客户要求。

- 在染色过程中严格控制温度、湿度等参数,确保染色的稳定性和持久性,注重环保和可持续性,采用环保染料和绿色染整工艺。

- 在样品测试阶段要充分了解客户的需求和产品特性,以便更好地满足客户要求。

- 在跟单过程中要注重沟通与协调,确保各个环节的顺利进行,及时解决客户的问题和疑虑,提高客户满意度。

英文表格补充说明

以下是纺织品染色跟单过程中的英文表格补充说明:

纺织品染色工艺流程说明

| 步骤 | 描述 |

|---|---|

| 材料准备 | 选择合适的染料和染色工艺 |

| 样品测试 | 进行样品测试,确保染料的颜色、牢度等符合客户要求 |

| 染色操作 | 在专业染料处理车间进行染色 |

| 质量检测 | 对染色后的纺织品进行质量检测 |

案例分析示例(英文)

Example Case Analysis: A知名纺织品品牌染色跟单过程

| 步骤 | 描述 | 材料选择 | 样品测试 | 染色操作 | 质量检测结果 | 客户反馈 |

|---|---|---|---|---|---|---|

| 材料选择 | 选择高品质的染料和染色工艺 | 高品质染料 | 严格样品测试 | 先进的染色技术 | 颜色鲜艳、质地柔软、手感舒适等 | 客户高度认可和好评 |

| ...(其他注意事项) |

纺织品染色跟单是一项复杂而重要的工艺环节,需要综合考虑多个因素,在跟单过程中,需要注重沟通与协调,确保各个环节的顺利进行,还需要不断优化和改进染色工艺和技术,提高染色的稳定性和持久性,满足客户对高品质纺织品的期望。

Articles related to the knowledge points of this article:

Shanghai Jingqing Textiles:The Fabric of Innovation in a Modern City

The Evolution and Impact of Shaoxing Yifeng Textiles

Stylizing Success with the Timeless Legacy of Shishi Jinkai Textiles

The Fabric of Success:A Case Study on Fujian Tianyuan Textiles

The Fabric of Education:Defining the Materiality of School Bags

A Journey into the World of Fabrics with Laughing Leaf Textiles