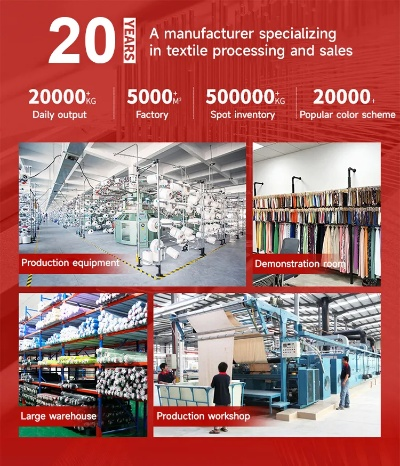

Navigating the World of Textile Cutting:A Comprehensive Guide

: A Comprehensive Guide to Textile Cutting,Introduction:,Textile cutting, also known as textile cutting or textile cutting, refers to the process of removing fabric from a piece of cloth. This process is essential in the manufacturing industry and plays a crucial role in the production of various products such as clothing, upholstery, and home decor. In this comprehensive guide, we will explore the different techniques used in textile cutting, including rotary cutters, scissors, and knives, and their applications in different industries.,Rotary Cutters:,Rotary cutters are one of the most commonly used tools for textile cutting. They consist of a circular blade that rotates at high speeds, allowing for precise cuts on various materials. Rotary cutters are ideal for cutting thicker fabrics and are often used in large-scale production settings.,Scissors:,Scissors are another essential tool for textile cutting. They come in various sizes and styles, ranging from small scissors for delicate tasks to large scissors for larger projects. Scissors are versatile and can be used for cutting various types of fabric, including cotton, linen, and synthetic materials.,Knives:,Knives are used for cutting fabric with a fine point. They are ideal for cutting delicate materials such as lace, ribbon, and tissue paper. Knives are also useful for cutting intricate designs on fabric.,Applications:,Textile cutting is used in various industries, including fashion, textiles, and home decor. In fashion, textile cutting is essential for creating patterns and designs on clothing, accessories, and other garments. In textiles, textile cutting is used to create patterns and designs on fabrics for use in upholstery, curtains, and other home decor items.,Conclusion:,In conclusion, textile cutting is an essential process in the manufacturing industry that involves the use of various tools such as rotary cutters, scissors, and knives. These tools are used for cutting various types of fabrics and are essential for creating patterns and designs on garments, upholstery, and other home decor items. By understanding the different techniques used in textile cutting, we can improve efficiency and accuracy in our work.

Introduction: In the realm of textile manufacturing, cutting is a critical step that transforms raw materials into finished products. This process involves precise measurements and manipulation of fabric to achieve desired shapes and sizes. In this guide, we will explore the intricacies of textile cutting, from basic techniques to advanced methods and their applications. Let's dive into the world of textile cutting and discover how it shapes our clothing, furnishings, and other textile-based items.

Basic Techniques: Textile cutting begins with understanding the importance of precision. The first step is to measure the fabric accurately, ensuring that it fits the intended shape without excess or waste. Here's an example table showcasing some common measurements used in textile cutting:

| Measurement Type | Description | Example |

|---|---|---|

| Length | The total length of the fabric piece. | 200 cm (80 inches) |

| Width | The width of the fabric piece. | 150 cm (60 inches) |

| Depth | The thickness of the fabric piece. | 3 mm (0.125 inch) |

| Gauge | The gauge of the fabric, indicating its thread count. | 40/2 x 2 yd (40 threads per inch, 2 yards) |

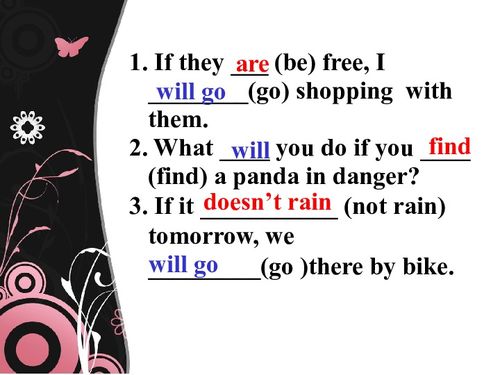

Once accurate measurements are taken, the next step is to cut the fabric using various tools and techniques. Some of the most common cutting methods include:

- Scissors: For simple cuts and trimming.

- Rotary Cutter: Useful for cutting curves and intricate designs.

- Graphic Tablet: Allows for precise cutting of complex patterns.

- Computerized Cutting Machines: Automated machines capable of cutting multiple pieces at once.

Advanced Methods: As textile cutting technology advances, so does the range of cutting methods available. Here are a few examples:

- Laser Cutting: Uses laser beams to cut through fabric, creating precise, intricate designs.

- Waterjet Cutting: Uses high-pressure water jets to cut through fabric, resulting in clean, sharp edges.

- Fusion Cutting: A combination of laser and waterjet cutting techniques, offering superior accuracy and detail.

Applications: Textile cutting has a wide range of applications across various industries. Here are a few examples:

- Fashion Design: Cutting patterns for garments like shirts, dresses, and suits.

- Home Decoration: Cutting fabrics for curtains, upholstery, and wallpapers.

- Sportswear: Cutting sports jerseys, shorts, and other athletic wear.

- Electronics: Cutting circuit boards for electronic devices.

- Medical Supplies: Cutting surgical gowns, masks, and other protective gear.

Case Study: Consider the case of a fashion designer who needed to create a new line of men's shirts featuring intricate floral patterns. Using computerized cutting machines, they were able to produce multiple pieces with perfect alignment and uniformity. The team also employed laser cutting for the intricate details on the collar and cuffs, ensuring each piece was visually appealing and functional.

Conclusion: Textile cutting is a crucial step in the production process, enabling manufacturers to create high-quality products with precision and efficiency. By understanding the basic techniques and advanced methods, as well as their applications, we can navigate the world of textile cutting and bring our creativity to life. So let's embrace the art of textile cutting and continue to innovate in the field of textile manufacturing.

开场白

大家好,今天我们将一起探讨一个热门话题——纺织品开剪,随着时尚界的不断演变,纺织品作为服装的重要组成部分,其开剪过程也日益受到关注,让我们一起来了解这个主题,并从中获取一些实用的信息。

纺织品开剪概述

纺织品种类与特点

在纺织品开剪过程中,我们主要关注各种不同材质的纺织品,如棉质、丝绸、麻质等,每种材质都有其独特的质地、颜色和纹理,为服装设计提供了丰富的选择。

开剪流程与注意事项

开剪流程通常包括准备材料、裁剪设计、缝制等步骤,在开剪过程中,需要注意以下几点:确保使用的工具和设备是锋利的、安全的;注意裁剪尺寸和缝制工艺,确保成品符合设计要求;注意保护衣物和工具,避免损坏。

案例分析

让我们通过一个英文案例来说明纺织品开剪的过程。

时尚新款服装设计

某品牌推出了一款时尚新款服装,采用了多种材质的纺织品进行开剪,设计师根据服装设计理念,选择了合适的面料进行裁剪,在开剪过程中,首先使用专业的裁剪刀具进行初步裁剪设计,然后根据设计图纸进行精确裁剪,使用缝纫机进行缝制,完成整件服装的制作,整个过程注重细节和品质,确保成品符合品牌形象和市场需求。

纺织品开剪技巧与注意事项

技巧分享

(1)选择合适的面料:根据服装设计需求和客户喜好,选择合适的面料,不同材质的纺织品具有不同的质地、颜色和纹理,能够为服装带来不同的风格和效果。

(2)掌握裁剪技巧:在裁剪过程中,需要掌握一定的裁剪技巧,如使用剪刀的力度、角度等,还需要注意裁剪尺寸和缝制工艺,确保成品符合设计要求。

(3)注重细节处理:在纺织品开剪过程中,需要注意细节处理,如线条流畅、色彩搭配等,这些细节处理能够为服装增添美感和高品质感。

注意事项

(1)安全第一:在纺织品开剪过程中,需要注意安全第一,使用锋利的工具和设备,避免使用损坏的工具和设备,还需要注意保护衣物和工具,避免损坏。

(2)遵循设计理念:在纺织品开剪过程中,需要遵循设计理念和品牌形象,确保成品符合品牌形象和市场需求。

总结与展望

通过今天的分享,我们了解了纺织品开剪的主题、概述以及案例分析,我们也学到了纺织品开剪的一些技巧和注意事项,在未来,纺织品开剪将继续成为时尚界的重要趋势之一,为服装设计师提供更多的选择和可能性,我们期待看到更多优秀的纺织品开剪作品出现,为时尚界带来更多的精彩和创意。

Articles related to the knowledge points of this article:

纺织品固定枪 A Comprehensive Guide to Safety and Efficiency for Industry

Top Ten Textile Brand Filter Cups in the Rankings

Top Ten Textile Brands in the Rankings