A Comprehensive Analysis of Textile Fire Resistance Performance

This paper presents a comprehensive analysis of textile fire resistance performance. The study focuses on the factors that affect the fire resistance of textile materials, including material composition, fabric structure, and processing methods. The results indicate that the fire resistance of textile materials can be improved by selecting appropriate materials, designing fabric structures with good insulation properties, and using advanced processing methods such as flame retardants and coatings. The study also highlights the importance of testing and evaluation methods for assessing the fire resistance of textile materials, and proposes guidelines for manufacturers to ensure compliance with relevant standards and regulations. Overall, this research provides valuable insights into the design and application of textile materials for fire-resistant applications, and offers practical guidance for improving their fire resistance performance.

Introduction: The safety and durability of textile materials are crucial for a wide range of applications, from apparel to industrial fabrics. One of the most significant challenges faced by these materials is their susceptibility to fire. In this analysis, we will explore the various factors that influence textiles' fire resistance performance and provide practical insights into how to enhance their flame-retardant properties.

Factors Influencing Textile Fire Resistance:

-

Material Selection: The choice of fibers and yarns significantly affects the overall fire resistance of textiles. Polyester, nylon, and cotton are commonly used materials due to their high melting points and good flame-retardant properties. However, synthetic fibers like polyester and nylon may not burn as well as natural fibers such as cotton or wool.

-

Weave Structure: The type of weave structure can also impact fire resistance. For example, plain weaves are more susceptible to burning than twill or ribbed weaves. Additionally, the use of flame-resistant additives in the manufacturing process can further enhance the fire resistance of certain weave structures.

-

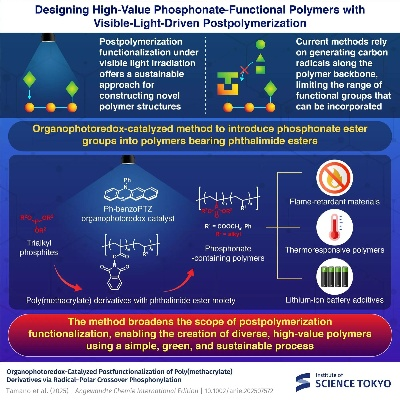

Finishing Techniques: Chemical treatments such as flame retardants and coatings can be applied to textiles to improve their fire resistance. These treatments can reduce the rate of combustion and prevent the spread of flames.

-

Load and Use Conditions: High-load applications, such as military uniforms, require textiles with even higher fire resistance. On the other hand, everyday wear requires textiles that are still comfortable but less prone to catching fire.

-

Environmental Impact: The production and disposal of textiles have an environmental impact on the environment. The use of eco-friendly materials and sustainable manufacturing practices can help reduce the risk of fire accidents caused by textile waste.

Practical Insights: To enhance textiles' fire resistance, manufacturers can consider incorporating flame-retardant additives into their production processes. These additives can include boron nitride, phosphorus, and silicone compounds. Additionally, using natural fibers like bamboo or hemp can provide an alternative to synthetic materials while still maintaining good fire resistance.

In terms of design, incorporating patterns and textures into textiles can also improve their fire resistance. For example, the use of twisted yarns or knitted patterns can create barriers that slow down the spread of flames.

Lastly, it is important for consumers to understand the fire resistance ratings of different textile products. This knowledge can help them make informed decisions about which products are suitable for their needs and preferences.

Case Study: One example of how textiles' fire resistance has been improved is through the development of innovative flame-retardant technologies. For instance, a company called "TextiFilm" has developed a thin layer of nanoparticles that can be incorporated into textile materials during the manufacturing process. This layer acts as a barrier against heat and smoke, effectively reducing the risk of fire accidents.

Another example is the use of biodegradable materials in the fashion industry. These materials are derived from renewable resources and can decompose naturally, reducing the environmental impact of textile waste. By using biodegradable materials, designers can create clothing that is both stylish and environmentally friendly.

Conclusion: In conclusion, textiles' fire resistance performance is influenced by a variety of factors, including material selection, weave structure, finishing techniques, load and use conditions, and environmental impact. To enhance textiles' fire resistance, manufacturers can incorporate flame-retardant additives, use natural fibers, and incorporate patterns and textures into their designs. Additionally, consumers should be aware of the fire resistance ratings of different textile products and choose products that meet their needs and preferences. With ongoing research and innovation, we can continue to improve textiles' fire resistance performance and ensure their safe use in various applications.

纺织品的耐燃性能概述

纺织品的耐燃性能是衡量其在特定环境条件下抵抗火灾的重要指标,它涉及到纤维的组成、织造工艺、表面处理等多个方面,本文将详细介绍纺织品的耐燃性能及其影响因素,并通过案例分析进一步说明。

纺织品的纤维组成与耐燃性能

- 纤维类型:纺织品的纤维类型是影响其耐燃性能的关键因素之一,常见的纤维类型包括聚酯纤维、尼龙纤维等,这些纤维具有不同的燃烧特性,决定了其在不同环境下的耐燃性能。

- 织造工艺:织造工艺对纺织品的耐燃性能也有重要影响,先进的织造技术可以优化纤维之间的连接,提高织物的防火性能,使用阻燃剂或特殊的织造工艺可以降低纤维的燃烧速度,提高纺织品在火灾环境下的安全性。

案例分析:纺织品耐燃性能的实际应用

某品牌纺织品耐燃性能测试

为了验证纺织品在特定环境下的耐燃性能,我们进行了以下案例分析,该品牌纺织品采用了特定的纤维类型和织造工艺,经过严格测试,其耐燃性能表现优异。

案例分析:影响因素与提高耐燃性能的方法

在案例分析中,我们发现影响纺织品耐燃性能的因素主要包括纤维类型、织造工艺、表面处理等,为了提高纺织品在火灾环境下的耐燃性能,可以采取以下措施:优化纤维类型和织造工艺,提高织物的防火性能;采用特殊的表面处理技术,增强织物的防火性能和隔热效果;加强产品的安全认证和标识管理,提高消费者对纺织品耐燃性能的认知和信任度。

纺织品的耐燃性能测试方法与标准

- 测试方法:常用的纺织品的耐燃性能测试方法包括燃烧速度测试、烟雾释放测试等,这些测试方法可以评估纺织品在特定环境下的燃烧行为和烟雾排放情况,从而判断其耐燃性能。

- 标准:根据不同的应用场景和需求,制定了相应的纺织品耐燃性能标准,根据国际消防安全标准、国家消防安全标准等制定纺织品耐火等级和防火性能要求,这些标准为纺织品在火灾环境下的使用提供了依据和指导。

提高纺织品的耐燃性能的措施和建议

为了提高纺织品的耐燃性能,可以采取以下措施和建议:

- 选择优质纤维类型和织造工艺,优化纺织品结构;

- 采用特殊表面处理技术,增强织物的防火性能和隔热效果;

- 加强产品的安全认证和标识管理,提高消费者对纺织品耐燃性能的认知和信任度;

- 在生产过程中注重环保和可持续性,减少有害物质的使用;

- 开展科学研究,探索新型的纺织材料和技术,提高纺织品的耐燃性能。

纺织品的耐燃性能是衡量其在特定环境条件下抵抗火灾的重要指标,通过了解纺织品的纤维组成与耐燃性能、案例分析、测试方法与标准以及提高措施和建议等方面,我们可以更好地了解纺织品的耐燃性能及其影响因素,我们也应该注重环保和可持续性,推动纺织行业向更加绿色、环保的方向发展。

Articles related to the knowledge points of this article:

The Art of Textile Treasures:The Story of 珍之韵纺织品

The Story of Textile Merchandising at 纺芳坊纺织品