The Essential Role of Textile Testing in Quality Assurance

In the realm of quality assurance, textile testing stands as a pivotal aspect that ensures the end product meets industry standards and consumer expectations. This critical role is evident in the rigorous process of ensuring that fabrics are free from defects such as color fading, shrinkage, and pilling. The testing methods employed range from visual inspections to advanced analytical techniques, each serving to identify and quantify specific issues with the fabric. Furthermore, these tests provide valuable information for manufacturers to make informed decisions about production processes and materials selection, ultimately leading to improved product quality and customer satisfaction. In conclusion, textile testing plays an essential role in the quality assurance process, providing critical insights into the performance and reliability of textile products.

Introduction: The textile industry is a vital sector, providing us with clothing, footwear, and various other materials that are essential for our daily lives. However, to ensure that the products we use are safe, durable, and meet the standards set by relevant regulations, it's crucial to conduct thorough testing on the raw materials and finished products. This article will discuss the importance of textile testing, including its benefits, methods, and practical applications. We'll also provide an example of how textile testing can improve quality assurance in a real-world scenario.

Benefits of Textile Testing: Textile testing plays a critical role in ensuring product safety and quality. It helps identify defects, measure performance, and comply with regulatory requirements. Here are some key benefits of textile testing:

-

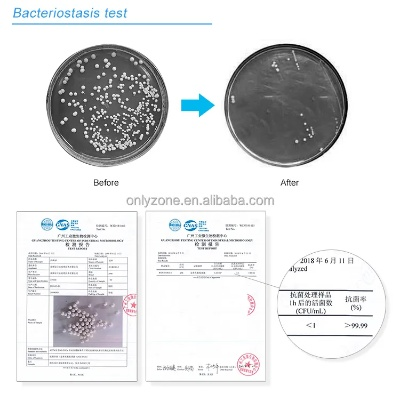

Prevention of Safety Hazards: Textile testing helps identify hazardous substances or materials that could cause harm if used in clothing or other textile products. For example, testing for toxic chemicals like flame retardants ensures that they do not release harmful fumes during fire or burn incidents.

-

Ensure Product Durability: Textile testing helps determine the resilience of fabrics against wear and tear. By assessing the strength and elasticity of materials, manufacturers can ensure that their products last longer and are more durable.

-

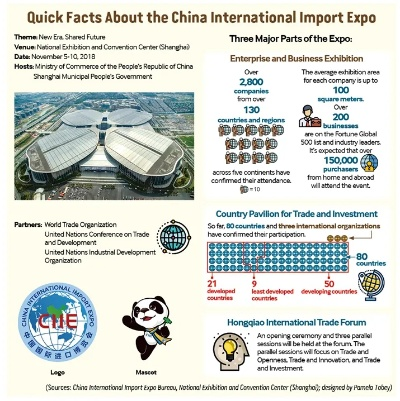

Compliance with Regulations: Textile testing is essential for complying with various regulations, such as the European Union's REACH regulation for chemicals, the American Standard for Occupational Safety and Health (OSHA) for workplace safety, and the Chinese National Standards for textile products. Testing helps companies stay compliant and avoid fines or penalties.

-

Improved Customer Satisfaction: When customers receive products that have been thoroughly tested, they trust the quality and safety of the product. This trust can lead to increased customer satisfaction and loyalty.

-

Cost Savings: Properly conducted textile testing can save money in the long run by preventing costly recalls or lawsuits due to defects. It also reduces waste by identifying unusable materials before they enter the production process.

Methods of Textile Testing: There are several methods used for textile testing, including:

-

Material Testing: This involves inspecting the physical properties of raw materials, such as fiber type, density, and colorfastness. Material testing helps identify potential issues before they affect the final product.

-

Manufacturing Process Testing: This includes tests that evaluate the quality of the final product after it has been produced. These tests may include dyeing, printing, and finishing processes.

-

Environmental Testing: This involves evaluating the environmental impact of textile products. For example, testing for water pollution caused by washing or laundering can help identify materials that are more sustainable.

-

End-Use Testing: This involves examining the performance of textile products under different conditions, such as temperature changes or exposure to sunlight. This helps ensure that products remain functional and aesthetically pleasing over time.

Practical Applications: In a real-world scenario, textile testing can be applied in various industries, including apparel, home furnishings, and industrial goods. For example:

-

Apparel Industry: In the apparel industry, textile testing is essential for ensuring that clothes are comfortable, durable, and free from harmful chemicals. Companies like Nike and Adidas conduct extensive testing to ensure their sportswear meets high standards for performance and safety.

-

Home Furnishings: Textile testing is crucial for ensuring that furniture and upholstery meet safety and durability standards. For example, furniture manufacturers may test for resistance to moisture, stains, and fading to ensure that their products last for many years.

-

Industrial Goods: Textile testing is essential for ensuring that industrial goods are safe and reliable. For example, automotive manufacturers may test tires for durability and performance under various conditions, while electronics manufacturers may test components for electromagnetic interference and heat dissipation.

Conclusion: Textile testing plays a vital role in ensuring the safety, quality, and sustainability of textile products. By identifying potential hazards, measuring performance, and complying with regulations, textile testing helps businesses deliver products that meet consumer expectations and protect the environment. In conclusion, investing in textile testing is an investment in both business success and public safety.

在日常生活中,纺织品是我们日常生活中不可或缺的一部分,它们不仅用于制作衣物、床单、窗帘等家居用品,还广泛应用于服装、鞋帽、装饰品等领域,对纺织品的质量和安全性进行检测,确保其符合相关标准和法规,对于保障人们的健康和安全至关重要,本文将围绕纺织品检测的必要性和案例展开讨论。

纺织品检测的必要性

保障消费者权益

纺织品作为人们日常生活中的必需品,其质量直接关系到消费者的使用体验和健康安全,通过纺织品检测,可以确保纺织品符合相关标准和法规,保障消费者的权益。

维护市场秩序

在纺织品市场中,质量参差不齐的产品存在,为了维护市场秩序,保障消费者的合法权益,对纺织品进行检测是必要的,只有通过严格的质量检测,才能确保纺织品的质量和安全性,从而维护市场的公平竞争。

保障产品质量和企业信誉

纺织品作为企业的重要产品,其质量直接关系到企业的声誉和经济效益,通过纺织品检测,可以确保企业生产的产品符合相关标准和法规,提高企业的信誉和竞争力,通过严格的质量控制,也可以提高产品的质量和性能,满足消费者的需求。

纺织品检测的案例说明

以下是一个纺织品检测的案例说明:

某品牌纺织品检测过程

该品牌在生产过程中,对每一批次的纺织品都进行了严格的检测,他们采用了多种检测方法,包括纤维含量检测、化学成分分析、物理性能测试等,通过对这些检测数据的分析,确保了纺织品的质量和安全性,他们还建立了完善的检测流程和标准操作程序,确保了检测结果的准确性和可靠性。

纺织品质量与安全法规的重要性

近年来,随着人们对纺织品质量安全要求的不断提高,国家对纺织品质量安全法规也日益严格,一些国家和地区已经出台了更加严格的纺织品质量安全标准,要求纺织品必须符合特定的质量和安全要求,这些法规的实施,不仅保障了消费者的权益,也促进了纺织行业的发展和进步。

纺织品检测的方法和工具

纤维含量检测

纤维含量检测是纺织品检测的重要方法之一,通过纤维含量检测可以了解纺织品的材质和性能,常用的纤维含量检测方法包括显微镜观察、光谱分析等。

化学成分分析

化学成分分析是通过对纺织品的化学成分进行测定和分析,了解纺织品的化学性质和组成,常用的化学成分分析方法包括元素分析、色谱分析等。

物理性能测试

物理性能测试是通过对纺织品的物理性能进行测试和分析,了解纺织品的性能和质量,常用的物理性能测试方法包括拉伸性能测试、耐磨性测试等。

纺织品检测对于保障消费者权益、维护市场秩序、保障产品质量和企业信誉具有重要意义,通过纺织品检测可以确保纺织品符合相关标准和法规,提高产品的质量和性能,满足消费者的需求,随着人们对纺织品质量安全要求的不断提高,纺织品检测的方法和工具也在不断更新和完善。

Articles related to the knowledge points of this article:

The Global Fabric of Bangladesh:An Overview of Dhaka International Textiles

The Art of Textile Labels and Their Incredible Benefits for Customers

The Journey of Hua Jia Textile Research and Development Center