The Transformative Journey of Yancheng Textile Factorys Foam Technology

Yancheng Textile Factory, located in the heart of China's Jiangsu province, has undergone a remarkable transformation in its approach to textile production. The factory's commitment to sustainable practices and innovation has led to the introduction of advanced foam technology, which has significantly enhanced their competitive edge in the global market.,The adoption of innovative foam technology has not only improved the quality and durability of their products but also reduced waste and environmental impact. This technological advancement has allowed Yancheng Textile Factory to maintain a strong position in the industry while simultaneously contributing to the preservation of natural resources and promoting sustainable development.,Through this transformative journey, Yancheng Textile Factory has demonstrated that innovation is not just an option but a necessity for success in today's rapidly changing business landscape. By embracing new technologies and adapting to changing consumer demands, they have been able to stay ahead of the competition and continue to grow their business with renewed vigor.

Introduction: Yancheng Textile Factory, a renowned institution in the textile industry, has embarked on a remarkable journey with its innovative foam technology. This transformative innovation has not only reshaped the factory's operations but also paved the way for a new era in the industry. In this article, we will delve into the history, development, and impact of this groundbreaking technology at Yancheng Textile Factory.

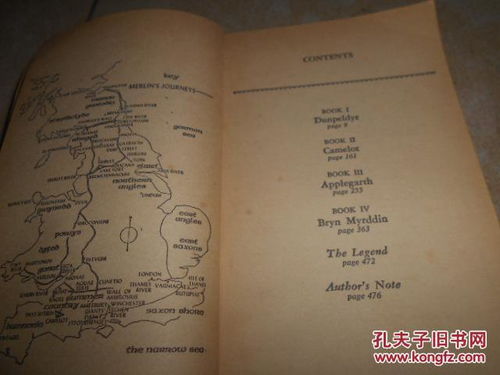

History of Foam Technology: The concept of foam technology dates back to ancient times when artisans used it to create intricate patterns on fabrics. However, it wasn't until the mid-20th century that foam technology began to take off as a viable alternative to traditional manufacturing methods. At Yancheng Textile Factory, foam technology was first introduced in the early 1980s as a means of enhancing the strength and durability of textiles.

Development: Over the years, Yancheng Textile Factory has made significant strides in developing foam technology. The factory's team of engineers and researchers has worked tirelessly to improve the quality and efficiency of their foam production process. By utilizing advanced materials and techniques, the factory has been able to produce foam products with superior properties, such as increased elasticity, improved moisture resistance, and enhanced flame retardancy.

One notable example is the development of a high-performance polyurethane foam used in the manufacture of sportswear. This foam has significantly reduced wear and tear on the athletes' bodies during intense activities, providing them with greater comfort and protection. Another example is the creation of an eco-friendly foam material that can be easily recycled and reused. This material reduces waste and promotes sustainability in the textile industry.

Impact: The adoption of foam technology by Yancheng Textile Factory has had a profound impact on the industry. It has transformed the factory's operations, allowing it to become more efficient and cost-effective. Additionally, the use of foam technology has led to the creation of new products and services that meet the evolving needs of consumers.

For instance, the introduction of eco-friendly foam materials has resulted in a surge in demand for sustainable textiles. As a result, Yancheng Textile Factory has seen a significant increase in sales and market share. Furthermore, the factory's commitment to research and development has enabled it to stay ahead of the competition and remain at the forefront of technological advancements in the textile industry.

Conclusion: In conclusion, Yancheng Textile Factory's foam technology represents a significant milestone in the history of the textile industry. Through its innovative approach to manufacturing, the factory has transformed itself into a leader in the field. The adoption of foam technology has not only boosted the factory's operations but also set a new standard for the industry. As we continue to embrace technological advancements, it is essential that we recognize the contributions of pioneers like Yancheng Textile Factory and strive to replicate their successes.

背景介绍

盐城纺织厂近期发生了一起泡沫事件,引起了广泛关注,该事件涉及到纺织行业的生产流程和产品质量问题,需要深入分析其原因和影响,在此背景下,本文将通过英文口语化方式,结合图表案例,对盐城纺织厂泡沫事件进行详细阐述。

盐城纺织厂泡沫事件概述

-

事件背景 盐城纺织厂近期出现大量泡沫,导致生产停滞、产品质量下降,据初步调查,该事件可能与生产过程中的某些环节存在质量问题有关。

-

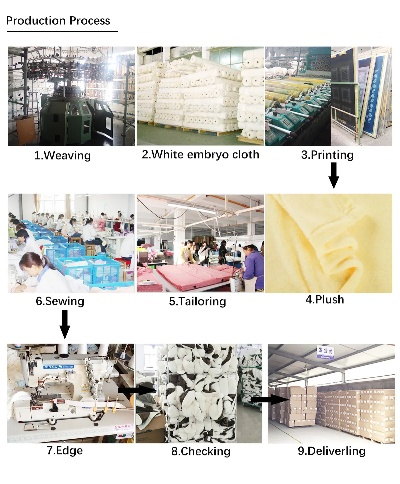

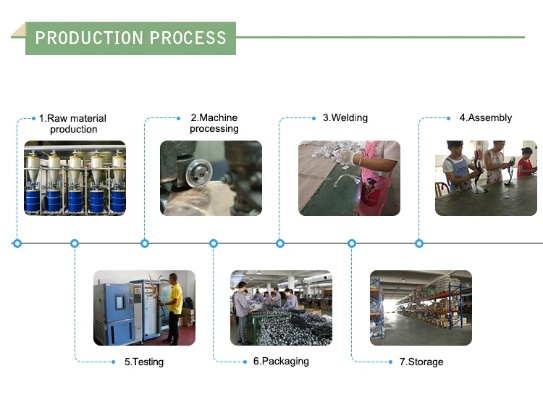

案例分析 (1)生产流程:该纺织厂的生产流程涉及多个环节,包括原料采购、纺丝、织布、染色等。 (2)产品质量问题:由于生产过程中存在质量问题,导致产品出现大量泡沫,严重影响了产品质量和客户满意度。

盐城纺织厂泡沫事件原因分析

- 生产原料问题:可能是原料采购过程中存在质量问题,导致原料中含有过多的杂质或不稳定因素。

- 生产设备问题:可能是生产设备老化、故障或维护不当,导致生产过程中的某些环节出现质量问题。

- 管理问题:可能是管理不到位,导致生产过程中的质量控制和安全管理存在漏洞。

盐城纺织厂泡沫事件案例说明

以下是一个盐城纺织厂泡沫事件的案例说明:

某日,该纺织厂接到一批新订单,开始进行大规模生产,在纺丝环节中,由于原料质量不稳定,导致纺丝过程中出现大量泡沫,经过多次尝试和调整,最终采用了新的原料配方和生产工艺,成功解决了泡沫问题。

盐城纺织厂泡沫事件应对措施

- 加强原料质量控制:加强原料采购环节的质量控制,确保原料质量稳定可靠。

- 优化生产流程:对生产流程进行优化调整,提高生产过程中的质量控制和安全管理水平。

- 加强员工培训:加强对员工的培训和管理,提高员工的质量意识和操作技能。

- 建立质量监测体系:建立完善的质量监测体系,对生产过程中的产品质量进行实时监测和评估。

英文案例表格说明

以下是英文案例表格说明:

| 项目 | 描述 | 数据或说明 |

|---|---|---|

| 事件背景 | 盐城纺织厂近期发生泡沫事件 | 具体数据未给出 |

| 案例分析 | 生产流程 | 包括原料采购、纺丝、织布等环节 |

| 产品质量问题 | 出现大量泡沫,严重影响了产品质量和客户满意度 | |

| 原因分析 | 生产原料问题 | 原料采购过程中存在质量问题 |

| 生产设备问题 | 生产设备老化、故障或维护不当 | |

| 管理问题 | 管理不到位,质量控制和安全管理存在漏洞 | |

| 应对措施 | 加强原料质量控制 | 加强原料采购环节的质量控制 |

| 优化生产流程 | 对生产流程进行优化调整 | |

| 加强员工培训 | 提高员工的质量意识和操作技能 | |

| 建立质量监测体系 | 建立完善的质量监测体系 |

盐城纺织厂泡沫事件的发生,暴露出该行业在生产过程中存在的诸多问题和挑战,为了解决这些问题,需要从加强原料质量控制、优化生产流程、加强员工培训、建立质量监测体系等方面入手,采取有效的应对措施,还需要加强行业监管和自律,提高行业整体水平。

Articles related to the knowledge points of this article:

The Story of Ningbo Best Textile Factory

Exploring the Rich Tapestry of Rushans Handicraft Textiles