The Fabrication Journey of Textiles:A Comprehensive Guide

This comprehensive guide delves into the fabrication journey of textiles, providing an in-depth understanding of the various stages involved in creating a piece of clothing or a textile product. From the selection and procurement of raw materials to the final assembly of a finished product, this guide covers all aspects of textile production.,The first chapter introduces the basic principles of textile production, including the importance of quality control and sustainability practices. It also discusses the different types of textile fibers and their properties, as well as the various techniques used to manipulate them into fabric.,The second chapter focuses on the manufacturing process, which includes several key steps such as weaving, knitting, and crocheting. Each technique requires careful attention to detail and is characterized by its unique strengths and limitations.,The third chapter explores the challenges faced by textile manufacturers, including issues related to labor, environmental impact, and economic viability. It also provides insights into how these challenges can be addressed through innovation and strategic planning.,In conclusion, this comprehensive guide provides a thorough overview of the fabrication journey of textiles, offering readers a valuable resource for those interested in learning more about this fascinating industry.

Introduction: Textiles, the fabric of our lives, are an integral part of human civilization. From the simplest cotton t-shirt to the most luxurious silk gown, textiles have a profound impact on our daily lives. In this article, we will delve into the manufacturing process that transforms raw fibers into high-quality textiles. Let's embark on a journey through the stages of production and see how each step contributes to the final product.

-

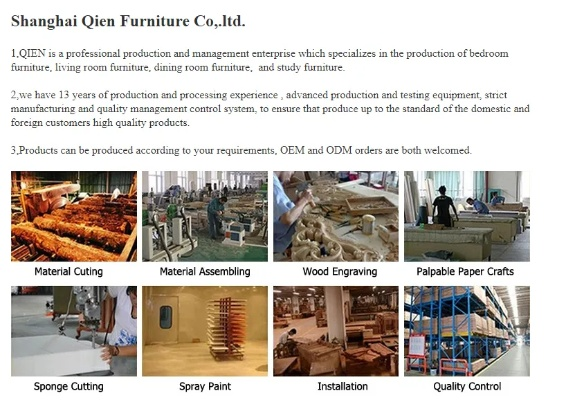

Raw Material Selection The first step in the textile production process is selecting the right raw materials. These include cotton, wool, synthetic fibers like polyester, and even natural fibers like bamboo and linen. Each material has its unique properties, such as strength, durability, and softness, which determine their suitability for various applications. For example, cotton is widely used for clothing due to its breathability and comfort, while polyester is preferred for its strong and durable properties in upholstery and carpeting.

-

Preparation of Fibers Before we can start weaving or knitting, the raw materials need to be prepared. This involves cleaning, carding, and combing the fibers to remove impurities and improve their texture. For instance, carding is the process of rolling and twisting the fibers to increase their surface area, making them easier to weave or knit. This step is crucial for the quality of the final product.

-

Weaving/Knitting Once the fibers are prepared, they enter the next stage of production - weaving or knitting. Weaving involves interlacing warp threads with weft threads to create a fabric, while knitting involves looping individual yarns together to form a seamless pattern. Both methods use different techniques to achieve the desired texture and design. For example, some textiles, such as denim jeans, are produced using a simple weaving technique, while others, like lace dresses, require intricate knitting patterns.

-

Dyeing and Printing After weaving or knitting, the fabric undergoes dyeing or printing to give it color and pattern. Dyes are added to the fabric during the dying process, altering its color tone and hue. Some textiles, like silk, are dyed using natural dyes derived from plants, while others, like polyester, are dyed using chemicals. Printing involves adding designs or patterns to the fabric using screens or other tools. This not only enhances the aesthetic appeal of the product but also adds value to the finished product.

-

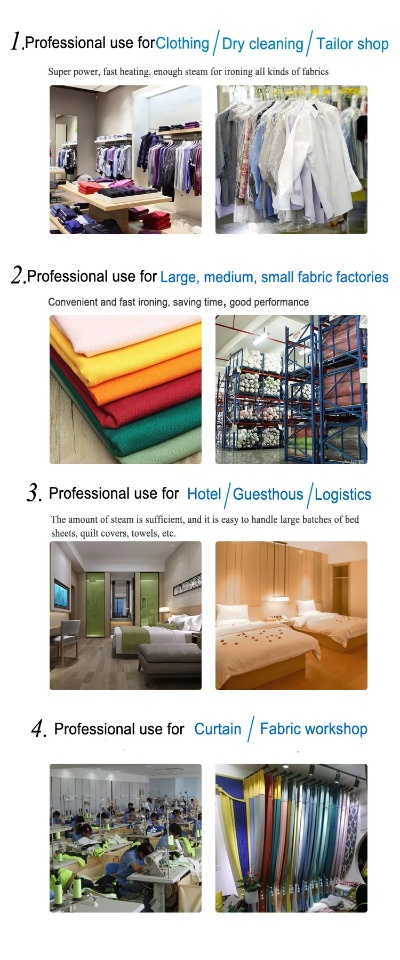

Finishing After dyeing and printing, the fabric needs to be finished to ensure its durability and appearance. This includes treatments such as steaming, softening, and finishing with waxes or coatings. For example, silk fabrics may be treated with a wax to enhance their shine and luster, while cotton fabrics may be softened with detergents to make them more comfortable to wear.

-

Packaging and Shipping Finally, the textile products are packaged and shipped to their final destination. Packaging plays a crucial role in protecting the product during transportation and storage. Different types of packaging are used depending on the product's size, weight, and fragility. For example, fragile textiles may be shipped in bubble wrap or placed inside cardboard boxes to prevent damage during transit.

-

Marketing and Sales Once the product is delivered to the customer, marketing and sales play a significant role in ensuring its success. This includes creating awareness about the product through advertising campaigns, social media platforms, and other channels. Additionally, providing excellent customer service and after-sales support can help build brand loyalty and encourage repeat business.

-

End of Life Finally, when the product reaches its end of life, it must be disposed of responsibly. This includes recycling, composting, or disposing of hazardous materials safely. By adopting sustainable practices, companies can minimize their environmental impact and contribute to a greener future.

Conclusion: In conclusion, the textile production process is a complex and multifaceted journey that starts with the selection of raw materials and ends with the disposal of waste. Each stage plays a vital role in producing high-quality textiles that meet the needs of consumers around the world. By understanding the steps involved in the production process, we can appreciate the hard work and dedication that goes into creating textiles that enrich our lives.

在纺织行业中,生产工序是确保产品质量和效率的关键环节,本文将详细介绍纺织品的主要生产工序,并通过英文案例说明来加深理解。

纺织品主要生产工序概述

原料采集与预处理

原料采集是纺织生产的起点,包括棉花、蚕丝、麻类等天然纤维的采集,预处理包括去杂、清洗、干燥等步骤,确保原料的质量和纯净度。

纺纱与织造

纺纱是将纤维通过一系列机械加工形成纱线的过程,织造则是将纱线按照设计要求编织成各种织物,这一工序包括纺纱机的工作原理、织布工艺等。

染整加工

染整加工是纺织品加工的重要环节,包括染色、印花、整理等工艺,染色是通过化学反应将纤维染色,印花则是通过图案设计在织物上印制图案,整理则是对织物进行平滑、柔软处理。

英文案例说明

以纺织品染整加工为例,介绍一个具体的英文案例。

案例:某品牌纺织品染整加工过程

原料采集:该品牌主要采用高品质的天然纤维作为原料,如棉、麻等,在采集过程中,严格筛选纤维质量,确保原料的纯净度和质量。

纺纱与织造:采用先进的纺纱技术,将纤维通过机器加工成细纱线,使用先进的织布工艺,将细纱线编织成各种织物,如棉质衬衫面料、麻质运动面料等。

染整加工:在染整加工环节,该品牌采用先进的染色技术和印花工艺,使织物呈现出鲜艳的颜色和独特的图案,对织物进行柔软处理,提高织物的舒适度和耐用性。

生产工序详解

-

原料采集与预处理:在原料采集阶段,需要选择优质的纤维原料,并进行严格的预处理,以确保后续工序的质量和效率,预处理包括去杂、清洗、干燥等步骤,需要使用专业的设备和工艺,确保纤维的质量和纯净度。

-

纺纱与织造:纺纱是纺织生产的关键环节,需要使用先进的纺纱技术,将纤维通过一系列机械加工形成纱线,使用织布工艺将纱线编织成各种织物,如棉质衬衫面料、麻质运动面料等,这一过程中需要注意纱线的质量和织物的结构与设计要求。

-

染整加工:染整加工是纺织品加工的重要环节,包括染色、印花、整理等多个步骤,染色是通过化学反应将纤维染色,使其呈现出所需的颜色和图案,印花是通过图案设计在织物上印制图案,提高织物的美观度和个性化程度,对织物进行柔软处理和抗皱处理等工艺,提高织物的舒适度和耐用性,还需要注意染料的选用和工艺控制等因素。

纺织品的主要生产工序包括原料采集与预处理、纺纱与织造、染整加工等多个环节,每个环节都需要严格控制质量和工艺,以确保最终产品的质量和性能,随着科技的不断进步和人们对纺织品品质要求的不断提高,纺织品的生产过程也在不断优化和改进。

Articles related to the knowledge points of this article:

Textile Factory Emergency Response Card

The Dynamic Landscape of Tianjins Textile Prices