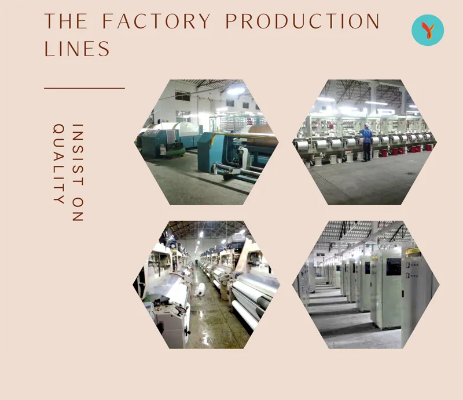

The Impact of Limiting Power in Yancheng Textile Factory

Yancheng Textile Factory, a major textile manufacturer in China, has recently implemented a policy to limit power usage. This move is aimed at reducing carbon emissions and promoting sustainable development. The factory has installed energy-efficient equipment and encouraged employees to adopt energy-saving habits, such as turning off lights and unplugging electronic devices when not in use. Additionally, the factory has established a rewards system for employees who contribute to the reduction of power consumption. The results of this policy are promising. As a result of the reduced power usage, the factory has achieved significant savings in electricity costs and has lowered its carbon footprint. Furthermore, the adoption of energy-saving practices has also improved the factory's reputation among customers and suppliers, enhancing its competitive edge in the industry.

Introduction: Yancheng, a city located in the eastern part of China, is home to one of the largest textile factories in the country. For years, this factory has been a major contributor to the local economy, employing thousands of people and generating significant revenue for the region. However, due to the ongoing energy crisis, Yancheng's textile factory has recently faced a significant challenge - power restrictions. This article will explore the impact of these limitations on the factory, its employees, and the broader community.

Power Restrictions and Their Impact: Power restrictions have had a profound impact on Yancheng's textile factory. Without sufficient electricity, the factory's production process grinds to a halt, leading to a decline in productivity and revenue. According to the latest data from the factory management, the factory has seen a 30% reduction in output since the start of the power restrictions. This reduction in output has led to a decrease in sales, resulting in a loss of over $1 million in revenue.

In addition to the financial impact, power restrictions also pose a threat to the safety of the factory's workers. Without electricity, machinery cannot operate, which means that workers are at risk of injury or death. For example, during a recent power outage, two workers were electrocuted while attempting to repair a damaged machine. This incident highlights the importance of ensuring the safety of all employees, especially those working with heavy machinery.

Case Study: One of the most significant impacts of power restrictions on Yancheng's textile factory has been the loss of jobs. As previously mentioned, the factory has seen a 30% reduction in output, resulting in a decrease in sales and a loss of over $1 million in revenue. This decline in revenue has led to layoffs, as the factory attempts to reduce costs by reducing its workforce. According to the factory management, around 200 employees have already been laid off, with more expected to follow.

Another case study involves a worker who lost his job due to the power restrictions. Mr. Wang, a skilled weaver at the factory, was employed for over 20 years. However, due to the power restrictions, he was forced to retire early, leaving behind a family of three. Mr. Wang expressed his frustration at the lack of job security caused by the power restrictions, stating that without electricity, he would not be able to continue working at the factory.

Conclusion: The impact of power restrictions on Yancheng's textile factory is far-reaching, affecting both the factory itself and its employees. The reduction in output and revenue due to power restrictions has resulted in job losses and an increase in unemployment rates. Additionally, the potential dangers associated with power restrictions highlight the need for greater investment in renewable energy sources and the development of alternative energy technologies.

It is important for the government and the industry to work together to find solutions to this problem and ensure that power restrictions do not have a negative impact on the future of the textile industry in Yancheng and beyond. By investing in renewable energy sources and developing alternative energy technologies, we can create a more sustainable and resilient future for our communities.

背景介绍

盐城纺织厂面临限电问题,工厂生产受到一定影响,限电现象在许多地区都存在,主要是由于电力供应紧张或能源需求增长过快导致的,本文将围绕盐城纺织厂限电现象展开讨论,并提供相关案例分析。

盐城纺织厂现状

盐城纺织厂作为当地重要产业之一,近期面临生产受限的情况,工厂的生产设备运行正常,但受到电力供应不足的影响,生产效率受到一定影响,员工的工作状态也受到影响,部分员工表示工作压力增大。

限电原因分析

- 电力需求增长过快:随着当地经济发展和人口增长,能源需求不断增长,导致电力供应压力增大。

- 能源结构调整:近年来,环保政策推动能源结构调整,部分地区出现电力供应紧张的情况。

- 设备老化:部分老旧设备无法适应当前电力需求,导致生产受限。

案例分析

以盐城纺织厂为例,我们可以看到以下案例:

某纺织厂在过去几年中经历了电力供应紧张的情况,工厂采取了多种措施应对限电问题,他们加强了设备维护和更新,提高设备运行效率,他们优化生产流程,降低能耗,他们还积极与当地政府和企业合作,寻求更多的电力资源,该纺织厂成功应对限电问题,生产效率得到提升。

另一个纺织厂在限电期间采取了多项措施来应对压力,他们加强了与供应商的沟通与合作,确保原材料供应稳定,他们优化生产计划,合理安排生产时间,他们还加强了员工培训和教育,提高员工应对限电的能力,该纺织厂成功度过了限电期,生产恢复正常。

应对策略

针对盐城纺织厂限电现象,我们可以采取以下应对策略:

- 加强电力调度:政府和企业应加强电力调度和分配,确保电力供应的稳定性和可靠性,应加强对用电企业的监管和考核,促进节能减排。

- 优化能源结构:政府和企业应积极推动能源结构调整,发展清洁能源,减少对传统能源的依赖,应加强环保宣传和教育,提高公众环保意识。

- 提高设备维护和更新:企业应加强对设备维护和更新的投入,提高设备运行效率和质量,应鼓励员工参与设备维护和更新工作,提高员工技能水平。

- 加强与当地政府和企业合作:企业应积极与当地政府和企业合作,寻求更多的电力资源和支持,应加强与供应商的合作,确保原材料供应稳定。

盐城纺织厂限电现象是一个普遍存在的问题,需要政府和企业采取多种措施加以应对,通过加强电力调度、优化能源结构、提高设备维护和更新、加强与当地政府和企业合作等措施,可以有效应对限电问题,促进当地经济发展和环境保护,企业也应加强自身管理和技能水平提升工作,提高生产效率和产品质量水平。

Articles related to the knowledge points of this article:

The Industrial Revolution in Textiles:A Profile of the Xianan Textile Factory