纺织品助剂立项要求

: Requirements for Project Initiative in Textile Additives,In the realm of textile manufacturing, the efficacy and sustainability of additives play a crucial role. The initiation of a project in textile additives necessitates adherence to specific criteria that ensure the product's quality, safety, and efficiency. These requirements encompass aspects such as research and development, material selection, process optimization, and regulatory compliance.,Firstly, the project must be grounded in rigorous research and development, whereby innovative solutions are sought to enhance the performance of textile materials. The focus should be on enhancing the durability, colorfastness, and environmental friendliness of textiles.,Secondly, the selection of materials is critical, with an emphasis on eco-friendly options that align with global sustainability goals. This includes selecting materials that are biodegradable, recyclable, and have minimal impact on the environment.,Thirdly, process optimization is essential to ensure that the additives produce results that meet industry standards while minimizing waste and resource consumption. This involves meticulous monitoring of production processes and adjustments made accordingly.,Lastly, regulatory compliance is paramount, ensuring that the project complies with all applicable laws and regulations governing textile additives. This includes obtaining necessary certifications and complying with safety standards.,In conclusion, the successful initiation of a textile additives project requires a comprehensive approach that incorporates research, material innovation, process optimization, and regulatory compliance. By meeting these requirements, the project can deliver high-quality, sustainable textile products that meet the demands of both consumers and the environment.

Introduction: The textile industry is a vital sector that contributes significantly to global economic growth and job creation. To maintain its competitive edge, manufacturers need to constantly innovate and improve their products through the use of various textile technologies and processes. One critical aspect of this innovation is the selection and application of appropriate textile aids, which can enhance the performance, quality, and durability of fabrics. In this article, we will discuss the key requirements for establishing a textile product development project using additives (textile aids) and outline some best practices for evaluating potential candidates.

Key Requirements:

-

Market Research: Before investing in textile aids, it is essential to conduct thorough market research to identify the latest trends, consumer preferences, and competition. This information will help you select the most effective and cost-effective textile aids for your product development project.

-

Product Development Process: The development process should include the formulation of new textile aids, testing them under various conditions, and assessing their impact on the final product's properties. It is also important to consider the manufacturing process and the overall cost of production.

-

Quality Control: Proper quality control measures must be in place to ensure that the textile aids meet the required specifications and standards. This includes testing for purity, stability, and compatibility with other materials used in the fabrication process.

-

Regulatory Compliance: It is crucial to comply with all relevant regulations and standards when developing textile aids. This includes ensuring that they are safe for human health and the environment, and that they do not contain harmful chemicals or substances.

-

Cost-Benefit Analysis: A thorough cost-benefit analysis is necessary to determine whether investing in textile aids is financially viable. This analysis should take into account the initial investment, ongoing costs, and potential returns on investment.

-

Risk Management: Any project involving new technology or materials has inherent risks. Therefore, it is important to establish a risk management plan to mitigate these risks and ensure the success of the project.

Best Practices:

-

Conduct Market Research: Use reputable sources such as industry reports, trade publications, and online forums to gather information about the latest trends and consumer preferences in the textile industry.

-

Collaborate with Industry Experts: Work closely with experts in the textile industry to gain insights into the latest developments and techniques. They can provide valuable guidance on selecting the right textile aids and developing effective product development processes.

-

Implement Quality Control: Establish strict quality control procedures to ensure that the textile aids meet the required specifications and standards. This includes regular testing and monitoring of the finished product to identify any defects or issues.

-

Stay Compliant with Regulations: Ensure that all textile aids comply with relevant regulations and standards, including those related to safety, environmental protection, and chemical content.

-

Conduct a Cost-Benefit Analysis: Analyze the financial implications of investing in textile aids and evaluate whether the benefits outweigh the costs. This analysis should consider factors such as initial investment, ongoing costs, and potential returns on investment.

-

Develop a Risk Management Plan: Identify potential risks associated with the project and develop a plan to mitigate them. This may include implementing contingency plans, securing funding, or seeking advice from industry experts.

Case Study: One example of a successful textile product development project using textile aids is the development of a high-performance polyester fabric by a leading textile manufacturer. The company conducted extensive market research to identify the latest trends in the polyester fabric industry and identified a gap in the market for a more durable and breathable material. After collaborating with experts in the industry, the company developed a new textile aid that improved the fabric's strength, flexibility, and moisture absorption capabilities. The new fabric was tested under various conditions and showed significant improvements in terms of wear resistance, color retention, and overall durability. The company then implemented strict quality control procedures and continued to monitor the finished product to ensure that it met all regulatory requirements. The new fabric was successfully launched in the market and quickly gained a strong foothold in the industry.

Conclusion: In conclusion, the successful development of textile products requires careful consideration of various factors, including market research, product development processes, quality control, regulatory compliance, cost-benefit analysis, and risk management. By following best practices and working closely with industry experts, manufacturers can create innovative textile products that meet the demands of consumers and remain competitive in the marketplace.

立项背景与目标

随着纺织行业的快速发展,纺织品助剂作为提升产品质量、优化生产效率的关键环节,其市场需求日益旺盛,为了满足这一市场需求,立项研究纺织品助剂具有重要性和必要性,本篇立项要求旨在明确纺织品助剂立项的基本条件、技术标准、市场需求以及预期效益。

立项要求概述

产品定位与市场分析

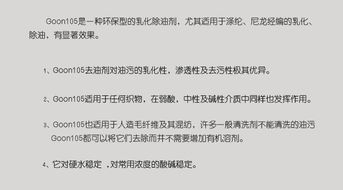

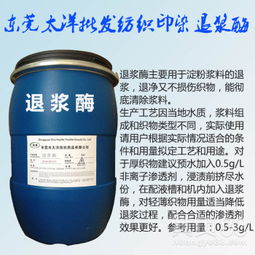

(1)产品定位:本纺织品助剂旨在满足纺织行业对功能性、环保性、高效性等多元化需求。

(2)市场需求分析:随着消费者对纺织品品质和环保性能要求的提高,纺织品助剂市场需求旺盛。

技术研发方向

(1)技术选型:选择具有自主知识产权、高效环保、符合纺织行业发展趋势的技术。

(2)研发策略:采用创新研发模式,注重研发效率与产品质量并重。

项目实施计划

(1)研发周期:预计研发周期为XX个月。

(2)关键节点:包括原料采购、实验室研究、小试生产、中试生产、产品认证等阶段。

项目预期效益

(1)经济效益:预期实现年产值XX亿元,利润XX亿元。

(2)社会效益:提升行业整体技术水平,促进产业升级。

案例分析

为了更好地说明纺织品助剂立项要求,以下结合案例进行详细说明。

某知名纺织企业成功研发的纺织品助剂项目

该企业成功研发的一款新型纺织品助剂,具有高效环保、功能性强的特点,该助剂在生产过程中能够有效提高纤维的强度和耐磨性,同时具备抗静电、抗紫外线等功能性指标,该产品已在市场上获得了良好的口碑和销售业绩,该企业通过自主创新研发,成功满足了市场需求,提升了行业整体技术水平。

立项要求补充说明

产品性能要求

(1)功能性:满足纺织行业对功能性需求,如抗皱、抗紫外线等。

(2)环保性:符合国家环保标准,无毒无害。

技术选型依据

(1)自主知识产权:采用先进的技术和工艺,拥有自主知识产权。

(2)高效环保:采用高效节能环保的工艺和设备,实现低能耗、低排放。

研发过程与实施计划表(表格形式)

以下是具体的研发过程与实施计划表,以供参考:

| 研发阶段 | 关键节点 | 实施计划 | 备注 |

|---|---|---|---|

| 原料采购 | 确定原料来源 | 采购优质原料 | 确保产品质量和稳定性 |

| 实验室研究 | 进行性能测试 | 采用先进的实验设备和方法 | 确保产品性能符合要求 |

| 小试生产 | 进行小批量生产 | 生产出样品进行性能测试 | 验证产品性能和稳定性 |

| 中试生产 | 进行规模化生产 | 进行产品认证和质量检测 | 确保产品质量符合标准 |

| 产品上市 | 完成产品认证和质量检测 | 开始销售 | 根据市场需求进行销售推广 |

总结与建议

纺织品助剂立项要求应明确产品定位与市场分析、技术研发方向、项目实施计划以及预期效益,在立项过程中,应注重产品性能要求和技术选型依据,同时结合案例进行说明,建议企业在立项过程中加强技术研发和人才培养,提高产品质量和竞争力,满足市场需求。

Articles related to the knowledge points of this article:

Broadening Horizons:Exploring the Global Reach of Wus Textiles

The Ugandan Textile Market A Global Perspective and Regional Insights

Stylizing Success with the Timeless Legacy of Shishi Jinkai Textiles

A Glimpse into the Dynamics of Suzhou Silk and Dyeing Market

An Extensive Guide to Printed Textiles:Types,Uses,and Case Studies