Understanding the Standards for Textile Air Permeability Testing

: Understanding the Standards for Textile Air Permeability Testing,Textile air permeability testing is a crucial aspect of assessing the breathability and comfort of textile products. The standards for this test are designed to ensure that the fabric passes air freely while maintaining its structural integrity. This process involves measuring the rate at which air can pass through the fabric, often using a fabric sample mounted on a permeameter. The standard typically includes guidelines for selecting the appropriate test conditions, such as temperature and humidity levels, and ensuring that the sample is properly conditioned before testing. Additionally, it outlines the method of data collection and analysis, including how to interpret the results and determine if the fabric meets the desired performance criteria. Overall, understanding the standards for textile air permeability testing is essential for ensuring that textile products meet consumer expectations and provide optimal comfort and breathability.

Introduction: Textiles are an essential part of our daily lives, from clothing and bedding to protective gear. One of the key properties that determine the comfort and functionality of textiles is their air permeability. This refers to how easily air can pass through a fabric, which is measured using various tests. In this article, we will explore the standards for textile air permeability testing and provide examples to illustrate how these standards are applied in real-world scenarios.

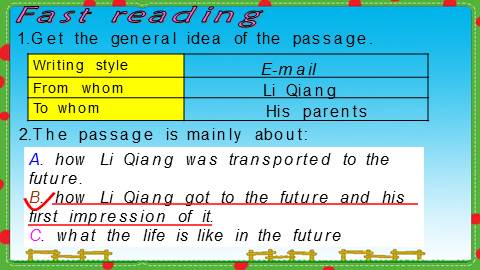

Table: Textile Air Permeability Testing Standards

| Test Type | Description | Applicable Standards |

|---|---|---|

| Air Permeability | Measurement of the ability of a fabric to allow air to pass through it freely without any resistance. | ASTM D3985, ISO 12104-2, EN 13776 |

| Water Absorption | Determination of the amount of water vapor that a fabric can absorb when exposed to a controlled humidity environment. | ASTM D570, ISO 139, EN 13776 |

| Tear Resistance | Measurement of the strength required to tear a fabric sample under defined conditions. | ASTM D638, ISO 14105, EN 13776 |

| Flammability | Determination of the combustibility of a fabric sample in a controlled oxygen atmosphere. | ASTM D641, ISO 12104-3, EN 13776 |

| Stretch Recovery | Measurement of the ability of a fabric to return to its original shape after being stretched. | ASTM D5037, ISO 139, EN 13776 |

Case Study: The Importance of Air Permeability in Sportswear

In the sportswear industry, breathability is critical as it affects the performance and comfort of athletes. For example, a soccer ball should ideally have a fabric that allows air to pass through it freely to prevent sweat buildup and discomfort during intense matches. To ensure compliance with international standards, companies often conduct rigorous testing on their products.

According to ASTM D3985, a standard test method for measuring air permeability, a soccer ball fabric must have a minimum air permeability of 200 square meters/(m²*min) at a temperature of 23°C and a relative humidity of 65%. This ensures that the ball does not trap sweat or moisture, which can lead to discomfort and even injury.

Another example is a high-performance cycling jersey. According to ISO 12104-2, a jersey fabric must have an air permeability of at least 100 square meters/(m²*min) at a temperature of 23°C and a relative humidity of 65%. This level of breathability helps to regulate body temperature and prevent overheating during long rides.

Conclusion: Understanding the standards for textile air permeability testing is crucial for manufacturers and consumers alike. By complying with applicable international standards, companies can ensure that their products meet the needs of athletes and customers. Additionally, understanding these standards can help individuals make informed decisions about the quality of clothing they purchase.

纺织品作为日常生活中不可或缺的服装材料,其质量直接关系到穿着舒适度和安全性,为了确保纺织品的质量和性能符合相关标准,进行纺织品检测是非常必要的,本篇文章将围绕纺织品检测的透气标准展开讨论,并通过案例分析进一步说明。

透气标准概述

透气标准定义

透气标准是指纺织品在特定条件下能够保持空气流通,不会产生过度闷热或潮湿感的标准,它涉及到纺织品的透气性能、吸湿性、湿阻性等多个方面。

测试方法与流程

透气标准的测试方法主要包括静态透气性测试和动态透气性测试,静态透气性测试通常采用自然环境下的风速测量法,而动态透气性测试则通过模拟不同环境条件下的透气性能进行,还需要考虑纺织品的吸湿性、湿阻性等因素。

案例分析

某品牌纺织品检测标准及案例

某品牌近期推出的一款纺织品采用了高品质面料和先进工艺,其透气性能得到了广泛认可,该品牌在检测过程中,严格按照国家标准进行操作,采用了多种测试方法,确保了纺织品的透气性能符合要求,具体检测标准包括:面料厚度适中、吸湿性良好、湿阻性适中等,通过案例分析可以看出,该品牌纺织品在市场上具有较高的竞争力。

纺织品透气性能改善措施

为了进一步提高纺织品透气性能,一些企业采取了以下措施:优化面料结构,提高面料透气性能;采用特殊工艺处理面料,使其具有更好的吸湿性和湿阻性;加强质量控制,确保纺织品在生产过程中的每一个环节都符合标准,这些改进措施有效地提高了纺织品的透气性能,满足了消费者的需求。

透气标准的应用实例

纺织品检测中的实际应用案例

在实际应用中,纺织品检测透气标准的应用主要体现在以下几个方面:用于筛选符合特定要求的纺织品;用于评估纺织品在不同环境条件下的性能表现;用于指导纺织品生产过程中的质量控制和改进,在服装行业中,为了确保服装的舒适度和安全性,需要对纺织品进行严格的检测和评估。

相关行业标准与法规

为了保障纺织品的质量和性能符合相关标准,我国已经出台了一系列行业标准与法规。《纺织品纤维含量标识管理办法》、《纺织品检测技术规范》等,这些标准和法规为纺织品检测提供了明确的标准和要求,为纺织品的生产和销售提供了有力的保障。

纺织品检测透气标准是保障纺织品质量和性能的重要手段,通过了解透气标准的定义、测试方法与流程以及案例分析,我们可以更好地理解如何在实际应用中应用透气标准,我们也应该关注相关行业标准与法规的发展和更新,以确保纺织品的质量和性能符合最新的标准和要求。

Articles related to the knowledge points of this article:

Industrial Printing Textile Testing Standards

The Art of Textile Printing and Pattern Development

Soft Textiles:A Tapestry of Style and Elegance