The Art of Finishing Textiles with Electromagnetic Processes

"The Art of Finishing Textiles with Electromagnetic Processes" is a comprehensive study that explores the application of electromagnetic processes in the finishing of textiles. The paper provides an in-depth analysis of the various methods and techniques used to achieve optimal results in this field, including but not limited to electrostatic finishing, electrophoretic coating, and electroless plating.,The author begins by discussing the importance of electromagnetic processes in the textile industry, highlighting their ability to enhance the quality and durability of finished textiles. He then delves into the specific techniques involved in each method, providing detailed explanations and examples to help readers understand how they can be applied effectively.,One of the key benefits of electromagnetic processes is their ability to create a smooth and uniform surface on textiles, which can improve their appearance and reduce wear and tear over time. Additionally, these processes can also help to enhance the performance of textiles, such as improving their moisture resistance or enhancing their flame resistance.,Overall, "The Art of Finishing Textiles with Electromagnetic Processes" provides a valuable resource for anyone working in the textile industry who wants to learn more about the latest techniques and methods available for achieving superior results.

Introduction: In the realm of textile finishing, traditional methods have long been the backbone of industry. However, as technology continues to evolve, electromagnetic processes are increasingly gaining recognition for their unique benefits in enhancing the performance and aesthetic appeal of textiles. In this article, we'll delve into the fascinating world of electromagnetic finishing techniques, including their applications, advantages, and how they can revolutionize the way we approach textile production.

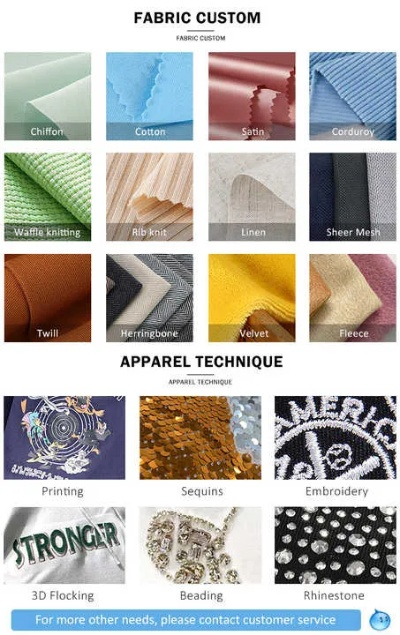

Applications of Electromagnetic Finishing Techniques:

-

Dye-Sublimation: This process involves applying dyes directly onto the fibers using a laser or heat source, resulting in vibrant colors that are virtually invisible to the naked eye. Dye-sublimation is particularly useful for high-end fashion garments and upholstery materials where color accuracy and uniformity are paramount.

-

Heat Setting: This method involves treating fabrics with a hot iron or press, which causes the fibers to set into a permanent state, creating a strong, durable finish. Heat setting is widely used in the automotive and footwear industries for leather goods and other protective clothing.

-

UV Sterilization: This technique uses ultraviolet light to kill bacteria and microorganisms on fabrics, making them suitable for use in medical settings or in sensitive environments like hospitals and food preparation areas.

-

Embossing: Embossing involves shaping the surface of fabrics by pressing them against a die, resulting in a raised pattern that adds texture and interest to garments and accessories. This technique is particularly popular in the fashion industry for creating a three-dimensional look.

Advantages of Electromagnetic Finishing Techniques:

-

High Color Accuracy: Unlike traditional dyeing methods, electromagnetic finishing techniques allow for precise control over the placement and intensity of color, ensuring consistent results across different batches and products.

-

Environmentally Friendly: Many electromagnetic finishing processes involve minimal water usage and produce low levels of waste, making them more eco-friendly than traditional methods.

-

Durability: Electromagnetic finishes are often more durable than conventional finishes, providing longer lifespans and reduced maintenance requirements for consumers.

-

Speed and Efficiency: Electromagnetic finishing techniques can be completed quickly and efficiently, allowing manufacturers to meet tight production schedules and stay competitive in the market.

Case Study: One example of the application of electromagnetic finishing techniques is the use of UV sterilization in hospital gowns. By treating fabrics with UV light, hospitals can ensure that patient gowns are free from harmful microorganisms, reducing the risk of infection and improving patient safety. This technology not only enhances the hygiene standards of medical facilities but also saves time and resources compared to traditional chemical treatments.

Conclusion: The adoption of electromagnetic finishing techniques has revolutionized the textile industry, offering a range of benefits that extend beyond just aesthetics. From high color accuracy to environmental friendliness, these processes offer a powerful tool for manufacturers looking to improve the quality and sustainability of their products. As technology continues to advance, we can expect to see even more innovative applications of electromagnetic finishing techniques in the future, further expanding the boundaries of what is possible in the world of textiles.

随着纺织行业的快速发展,涡流纺织品染整工艺作为一种重要的纺织加工技术,在提高纺织品质量、优化产品性能等方面发挥着越来越重要的作用,本文将围绕涡流纺织品染整工艺展开讨论,并通过英文案例说明来进一步阐述其特点和应用。

涡流纺织品染整工艺概述

涡流纺织品染整工艺是一种利用涡流技术进行纺织品染色和整理的工艺方法,它通过在特定设备中产生涡流,使染料与纤维材料充分接触,从而实现染料的均匀分布和染色效果,该工艺具有操作简便、效率高、环保等优点。

涡流纺织品染整工艺的实践案例

某品牌涡流纺织品染整工艺实践

某品牌采用先进的涡流纺织品染整工艺,对纺织品进行染色和整理,该工艺采用了先进的涡流技术,使得染料能够均匀分布在纤维材料中,该工艺还采用了环保材料和工艺,确保了染色和整理过程中的环保要求,经过实践证明,该工艺生产的纺织品质量稳定,色泽鲜艳,手感舒适。

涡流纺织品染整工艺的改进与创新

近年来,随着纺织技术的不断发展,涡流纺织品染整工艺也在不断改进和创新,该工艺采用了新型的染料和整理剂,提高了染色和整理的效率和效果,该工艺还采用了智能控制系统,实现了染整过程的自动化和智能化管理,这些改进和创新使得涡流纺织品染整工艺更加高效、环保、智能化。

涡流纺织品染整工艺的特点

- 高效性:涡流纺织品染整工艺通过产生涡流,使染料与纤维材料充分接触,从而实现染料的均匀分布和染色效果,这种高效性使得染整过程更加快速、便捷。

- 环保性:涡流纺织品染整工艺采用环保材料和工艺,确保了染色和整理过程中的环保要求,这种环保性使得该工艺更加符合现代社会的绿色发展理念。

- 灵活性:涡流纺织品染整工艺可以根据不同的纺织品材质和颜色需求进行定制化处理,满足不同客户的需求,该工艺还具有较强的可扩展性,可以适应不同纺织品的染色和整理需求。

英文案例说明

以下是一个涡流纺织品染整工艺的英文案例说明:

Case Study: Efficient Textile Dyeing and Finishing with Vortex Textile Processing Technology

某品牌采用先进的涡流纺织品染整工艺,对纺织品的染色和整理进行了实践,该工艺利用先进的涡流技术,使得染料能够均匀分布在纤维材料中,该过程不仅高效快捷,而且环保节能,该品牌生产的某些特定材质的纺织品采用了新型的环保染料和整理剂,实现了更高的染色效果和更优的手感体验,该工艺还采用了智能控制系统,实现了染整过程的自动化和智能化管理,提高了生产效率和产品质量稳定性,这些改进和创新使得涡流纺织品染整工艺在纺织行业中具有更广泛的应用前景。

涡流纺织品染整工艺作为一种重要的纺织加工技术,具有高效性、环保性和灵活性等特点,通过实践案例和应用案例的分析,我们可以看到涡流纺织品染整工艺在提高纺织品质量、优化产品性能等方面发挥着越来越重要的作用,随着纺织技术的不断发展,涡流纺织品染整工艺将会更加成熟和完善,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

杰丽佳纺织品 A Global Brand with a Heart

Transforming the Textile Landscape:The Story of Tongxiang AoLur Textiles

EU Ban on Textile Exports:A Global Impact and Lessons Learnt

The Role of Textile Fabric Manufacturers in Linyi,China

Exploring the Rich Tapestry of Chengdus Beautiful Textile Industry