The Fabrication of a Fire-Resistant Textile Formula:A Comprehensive Guide

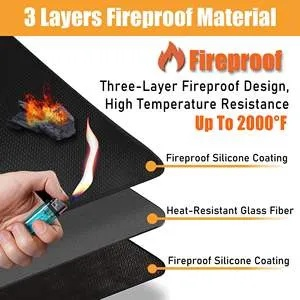

This article provides a comprehensive guide on the fabrication of a fire-resistant textile formula. The first step is to select the appropriate materials, such as flame-retardant agents and fibers, which can help reduce the spread of fire and minimize damage. Next, the formula must be mixed thoroughly to ensure even distribution of the materials. The mixture should then be applied to the fabric using a specialized machine or by hand. Finally, the fabric should be tested for its fire resistance properties before being used in any applications. With proper care and attention to detail, a fire-resistant textile formula can be successfully created and utilized in various industries.

Introduction: The fabrication of a fire-resistant textile formula is an essential process that ensures the safety and durability of clothing, carpets, and other textile products. In this guide, we will explore the various components that make up a successful fire-resistant textile formula and provide practical examples to help you understand how to create your own.

-

Fire Retardant Agents: Fire retardants are crucial in reducing the rate of combustion and preventing fire spread. Some common fire retardants include boron nitride, ammonium polyphosphate, and magnesium hydroxide. These agents work by forming a barrier on the surface of the fabric, preventing oxygen from reaching the fibers and causing a rapid reaction with the moisture present.

-

Fire-resistant Fibers: Fibers like cotton, polyester, and nylon are inherently resistant to fire, but they can be further enhanced with the addition of fire retardant agents. For example, polyester fibers can be treated with boron nitride to increase their flame resistance.

-

Chemical Additives: Certain chemicals can be added to the fabric to enhance its fire-resistance properties. These include antioxidants, which protect the fabric against UV damage and chemical reactions that can lead to fire; and flame retardants, which prevent the fabric from catching fire.

-

Textural Structures: The structure of the fabric also plays a role in its fire-resistance properties. For instance, knitted or woven structures can trap more air within the fabric, creating a barrier against heat and flame.

-

Processing Techniques: The manufacturing process itself can influence the fire-resistance properties of the fabric. For example, high-temperature dyeing and finishing techniques can improve the fire-resistance of some fabrics.

-

Testing and Verification: Once the formula has been developed, it must be tested and verified to ensure its effectiveness. This includes testing for fire resistance under controlled conditions, as well as assessing the impact on wearability and aesthetics.

Case Study: Consider the development of a fire-resistant carpet formula for a high-end hotel lobby. The formula would consist of a blend of natural fibers (like wool or silk) and synthetic materials (like polyester or nylon) treated with boron nitride and ammonium polyphosphate. The carpet would also have a unique pattern that would trap heat and prevent it from spreading quickly.

To test this formula, a series of tests would be conducted in a controlled environment, including exposure to flames and heat sources. The results would be evaluated based on factors such as the time it took for the carpet to catch fire, the extent of damage caused during the test, and the overall performance in terms of fire resistance and durability.

Conclusion: Creating a fire-resistant textile formula requires a combination of knowledge and expertise in various areas, including fire retardants, fiber science, chemical additives, processing techniques, and testing methods. By following the steps outlined above, you can develop a formula that meets the needs of your customers while ensuring the safety of your products.

纺织品阻燃配方概述

随着现代工业的快速发展,纺织品在日常生活和工业生产中的应用越来越广泛,为了满足不同领域的需求,我们研究开发了一系列纺织品阻燃配方,这些配方不仅提高了纺织品的耐火性能,还具有环保、节能等优点。

纺织品阻燃配方的主要成分及作用

-

阻燃剂:阻燃剂是纺织品阻燃配方中的关键成分,能够有效地延长纺织品在燃烧过程中的持续时间,降低火灾风险,常见的阻燃剂包括无机阻燃剂和有机阻燃剂,无机阻燃剂如氢氧化铝、氢氧化镁等,主要通过与有机基团反应形成稳定的化合物,从而达到阻燃效果,有机阻燃剂则通过提供额外的燃烧抑制作用,提高纺织品的耐火性能。

-

增强纤维:增强纤维是提高纺织品耐火性能的重要手段,常用的增强纤维包括玻璃纤维、碳纤维等,它们能够增强纺织品的热稳定性和机械强度。

纺织品阻燃配方实例分析

新型阻燃聚合物面料

某公司研发了一种新型阻燃聚合物面料,采用了先进的阻燃配方,该面料具有优异的耐火性能和环保性能,能够有效抵抗火灾风险,该面料采用了特殊的阻燃剂和增强纤维组合,经过特殊工艺处理后,具有优异的防火性能和舒适度。

多功能纺织品阻燃处理

某公司开发了一种多功能纺织品阻燃处理技术,可以应用于各种领域,该技术采用先进的阻燃配方,对纺织品进行全面的处理,包括表面处理、内部填充等,处理后的纺织品不仅具有优异的耐火性能,还具有环保、节能等优点。

纺织品阻燃配方的发展趋势

随着科技的不断进步和人们对环保、安全的需求不断提高,纺织品阻燃配方的发展趋势将更加注重环保、高效、安全等方面,纺织品阻燃配方将更加注重绿色制造、智能化生产等方面的发展,提高纺织品的耐火性能和环保性能,还将不断探索新的阻燃剂和增强纤维组合,提高纺织品的防火性能和实用性。

纺织品阻燃配方的实际应用案例

在实际应用中,纺织品阻燃配方的应用范围非常广泛,在消防服装、消防器材、家居用品等领域中,纺织品阻燃配方的应用非常普遍,随着人们对环保、安全的需求不断提高,纺织品阻燃配方的应用领域还将不断扩大。

纺织品阻燃配方是现代工业发展的重要产物,它不仅提高了纺织品的耐火性能和环保性能,还具有广泛的应用前景,随着科技的不断进步和人们对环保、安全的需求不断提高,纺织品阻燃配方的发展趋势将更加注重绿色制造、智能化生产等方面的发展,我们还将继续探索新的阻燃剂和增强纤维组合,提高纺织品的防火性能和实用性。

Articles related to the knowledge points of this article:

The Art of Embroidery on Thread A Closer Look at Yue Sheng Textiles