The Science Behind Textile Fire Retardancy:An Overview

This article provides an overview of the scientific principles behind textile fire retardancy. It explains how fire retardants are incorporated into textiles to inhibit the spread of flames and reduce the risk of fire damage. The article discusses the types of fire retardants used in textiles, including organic and inorganic compounds, and their effectiveness in preventing fires. It also explores the challenges faced by manufacturers in ensuring that fire retardant additives are properly applied and integrated into the fabric structure. Overall, this article provides a comprehensive understanding of the science behind textile fire retardancy and its importance in protecting people and property from fire disasters.

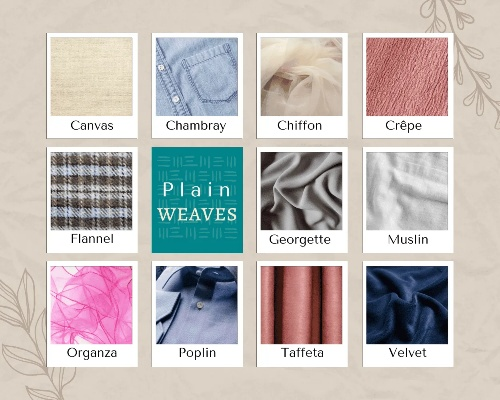

Introduction Textiles are an integral part of our daily lives, from clothing to furnishings. However, they can also pose a significant risk in the event of a fire due to their high level of combustible materials and lack of flame-retardant properties. This is where textile fire retardancy comes into play - a science that aims to make textiles more resistant to fire by incorporating flame-retardant chemicals or materials. In this article, we will explore the various mechanisms behind textile fire retardancy and provide examples of how these mechanisms work in practice.

Flame Retardant Mechanisms Textile fire retardancy is achieved through various mechanisms, including physical barriers, chemical reactions, and smoke suppression.

Physical Barriers Physical barriers refer to the use of materials that physically block or limit the spread of flames. These include:

| Material | Function |

|---|---|

| Polyester | Forms a rigid film that prevents direct contact with the fabric, reducing the rate of fire spread |

| Nylon | Acts as a barrier, preventing heat transfer to the fabric |

| Polyurethane | Creates a protective layer on the surface of the fabric, reducing heat absorption |

Chemical Reactions Chemical reactions occur when flame retardants react with the fabric's fibers or other components to create a protective layer that inhibits combustion. Some common flame retardants include:

| Flame Retardant | Function |

|---|---|

| Boron Phosphate | Reacts with cellulose, creating a protective coating that reduces the rate of combustion |

| Antimony Trioxide | Prevents the formation of combustible carbonaceous material during burning |

| Calcium hydroxide | Acts as a catalyst for the formation of calcium silicate, which forms a protective layer on the fabric |

Smoke Suppression Smoke suppression refers to the ability of flame retardants to reduce the amount of smoke produced during a fire. This is achieved by creating a barrier that prevents oxygen from reaching the fabric's fibers, thereby reducing the rate of combustion. Some examples of smoke suppressants include:

| Flame Retardant | Function |

|---|---|

| Polyvinyl Chloride (PVC) | Creates a barrier that prevents oxygen from reaching the fabric, reducing the rate of combustion |

| Polytetrafluoroethylene (PTFE) | Forms a barrier that prevents oxygen from reaching the fabric, reducing the rate of combustion |

| Calcium carbonate | Acts as a catalyst for the formation of calcium silicate, which forms a protective layer on the fabric |

Application of Flame Retardant Technology The application of flame retardant technology in textiles has been widely used in various industries, including apparel, furniture, and electronics. Here are some examples of how these mechanisms work in practice:

-

Apparel Industry In the apparel industry, flame retardant technology is used to create clothing that is both stylish and safe. For example, polyester blended with nylon is often used in athletic wear to provide a durable, breathable, and flame-resistant fabric. Additionally, antimony trioxide is added to cotton fabrics to prevent them from catching fire during washing.

-

Furniture Industry Furniture made from flame-retardant materials is essential for homes and offices. For instance, PVC is commonly used in upholstery fabrics to provide a barrier against fire and smoke. Similarly, polyvinyl chloride (PVC) is used in carpeting to prevent it from catching fire and spreading smoke.

-

Electronics Industry In the electronics industry, flame retardant technology is crucial for protecting electronic devices from fire damage. For example, epoxy resin is used in the production of circuit boards to provide a flame-resistant surface that prevents the device from catching fire. Additionally, antimony trioxide is added to plastic circuit boards to prevent them from catching fire during manufacturing.

Conclusion Textile fire retardancy is a complex field that involves the integration of various mechanisms to create durable, flame-resistant textiles. By understanding the different mechanisms behind textile fire retardancy, we can better appreciate the importance of these technologies in protecting our lives and property. As technology continues to advance, we can expect even more innovative solutions to emerge, making textiles safer and more sustainable in the future.

纺织品阻燃机理概述

纺织品阻燃是指通过一系列科学手段和技术,降低或消除纺织品在特定环境或条件下燃烧的风险,其阻燃机理主要包括热稳定作用、化学阻燃剂、物理防护等。

热稳定作用

-

热分解反应:纺织品在高温下会发生热分解反应,释放出气体和热量,有助于抑制火焰的蔓延。

-

炭化过程:某些纺织品在高温下会形成炭化层,形成一层隔热屏障,进一步降低燃烧的风险。

化学阻燃剂

-

卤化物阻燃剂:卤化物阻燃剂通过与有机物质反应,形成不燃烧或低燃烧的化合物,从而达到阻燃效果。

-

氧化物阻燃剂:氧化物阻燃剂通过与有机物质反应,生成稳定的氧化物,起到良好的阻燃效果。

案例说明

以纺织品阻燃为例,我们可以引用一个具体的案例来说明其阻燃机理。

某新型阻燃纺织品的应用

该新型阻燃纺织品采用了先进的化学阻燃剂技术,通过添加适量的阻燃剂,提高了纺织品的热稳定性和燃烧安全性,在实际应用中,该纺织品在高温环境下表现出良好的阻燃性能,有效降低了火灾风险。

表格补充说明

纺织品阻燃机理相关参数对比

| 参数 | 热分解反应 | 炭化过程 | 化学阻燃剂 |

|---|---|---|---|

| 效果 | 有效降低燃烧风险 | 提供隔热屏障 | 卤化物、氧化物等 |

| 应用领域 | 服装、家居用品等 | 其他工业制品 | 防火材料、建筑材料等 |

纺织品阻燃机理主要包括热稳定作用、化学阻燃剂和物理防护等,通过添加适当的化学阻燃剂,可以有效降低纺织品在特定环境下的燃烧风险,在实际应用中,新型阻燃纺织品的应用案例充分证明了其阻燃机理的有效性和实用性,随着科技的不断进步,纺织品阻燃技术将更加成熟和完善,为人们的生产生活提供更加安全可靠的保障。

Articles related to the knowledge points of this article:

Navigating the World of Textile Accounting

The Price Dynamics of Lavender Textile Products:A Comprehensive Look