The Evolution of High-Yield Textile Supply Chains:A Comprehensive Analysis

"The Evolution of High-Yield Textile Supply Chains: A Comprehensive Analysis",High-yield textile supply chains have undergone significant transformations in recent years, driven by advancements in technology, changing consumer preferences, and increased global competition. This paper provides a comprehensive analysis of the evolution of these supply chains, examining how they have evolved from traditional models to more efficient and sustainable practices.,One of the key drivers of this evolution has been the increasing demand for high-quality and low-cost textile products, which has led to a shift towards using more sustainable materials and processes. This has resulted in a greater emphasis on green manufacturing practices, such as reducing waste and emissions, using renewable energy sources, and adopting circular economy principles.,Another important factor has been the rise of digital technologies, particularly in the areas of data analytics and artificial intelligence. These tools are being used to optimize supply chain operations, improve inventory management, and enhance customer experience. For example, machine learning algorithms can be used to predict demand trends and optimize production schedules, while sensors can be installed in factories to monitor real-time performance and identify potential bottlenecks.,Despite these improvements, there remain challenges that must be addressed in order to fully realize the potential of high-yield textile supply chains. These include issues related to regulatory compliance, workforce training and development, and the need for continued innovation and investment in new technologies and business models.,Overall, the evolution of high-yield textile supply chains is a complex and dynamic process that requires ongoing attention and investment. By embracing new technologies and best practices, businesses can build more sustainable and efficient supply chains that meet the demands of modern consumers and industry."

In the world of textiles, the supply chain is often considered a critical backbone that supports the growth and success of high-yielding enterprises like "High-Yield Textile". This topic is not only essential for understanding how textile companies manage their inventory and logistics but also crucial for predicting future trends in the industry. In this article, we will delve into the evolution of high-yield textile supply chains, analyze key factors affecting their performance, and highlight successful case studies to provide valuable insights for other textile companies.

Evolution of High-Yield Textile Supply Chains

Textile supply chains have undergone significant changes over the years, adapting to the ever-evolving demands of consumers and global markets. In the early days, these chains were characterized by a centralized approach, with manufacturers producing textiles and then distributing them to retailers through a few major players. However, as consumer preferences shifted towards more personalized and sustainable products, the supply chain began to diversify.

Today, high-yield textile supply chains are highly complex and involve multiple stakeholders, including raw material suppliers, textile manufacturers, distributors, retailers, and end-users. These chains are characterized by flexibility, responsiveness, and the ability to adapt to changing market conditions. They rely on advanced technologies such as artificial intelligence (AI) and big data analytics to optimize production and distribution processes, reduce waste, and improve customer satisfaction.

Key Factors Affecting High-Yield Textile Supply Chain Performance

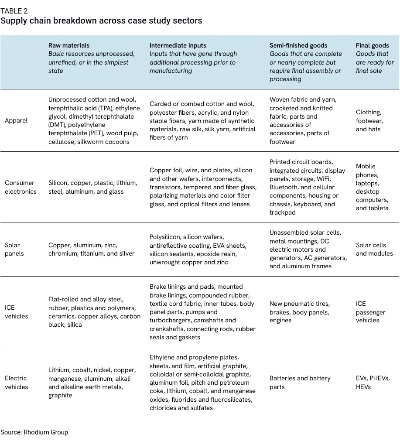

The performance of high-yield textile supply chains is influenced by several key factors. One of the most critical is the availability and quality of raw materials. Raw materials are the foundation of any textile product, and their quality directly affects the final product's quality and price point. Therefore, ensuring that suppliers offer consistent and reliable raw materials is crucial for maintaining high-yield performance.

Another important factor is logistics and transportation. Properly managed logistics can significantly reduce delivery times, minimize losses, and ensure that products reach their destination quickly and safely. Additionally, advances in technology such as drones and autonomous vehicles are transforming the way textiles are transported, making it possible to deliver products more efficiently and cost-effectively.

Finally, customer engagement is also a critical factor in high-yield textile supply chain performance. By understanding customers' needs and preferences, textile companies can develop customized products that meet their expectations. This not only enhances customer satisfaction but also drives repeat business and referrals.

Successful Case Studies

To illustrate the importance of these factors, let us take a look at two successful case studies in the world of high-yield textile supply chains.

Case Study 1: Zara

Zara is one of the world's leading fast fashion brands, known for its ability to keep up with the latest trends and designs. To achieve this, Zara relies heavily on its supply chain, which includes cutting-edge technologies and efficient logistics. For example, Zara has implemented a system called "Zara Next," which uses AI to predict customer demand and optimize inventory levels. Additionally, Zara's partnership with suppliers allows for quick response times to market changes and ensures that products are delivered promptly to stores worldwide.

Case Study 2: H&M

H&M is another well-known fast fashion brand that has successfully leveraged its supply chain to maintain high-yield performance. H&M's supply chain is characterized by its focus on sustainability, with a strong commitment to reducing waste and using eco-friendly materials. For example, H&M has implemented a program called "H&M Renew," which aims to reduce its environmental impact by using recycled materials and implementing energy-efficient manufacturing processes. Additionally, H&M's supply chain is highly responsive, allowing for quick adjustments to market trends and customer preferences.

Conclusion

In conclusion, the evolution of high-yield textile supply chains is a complex and dynamic process that requires constant innovation and adaptation. Key factors such as raw material availability, logistics and transportation, and customer engagement play a vital role in determining the success of these chains. Successful case studies such as Zara and H&M demonstrate the power of leveraging technology, sustainability, and responsiveness in achieving high-yield performance. As textile companies continue to evolve their supply chains, it is essential to stay ahead of the curve, adopting innovative solutions that enable them to meet the demands of the ever-changing market.

随着全球化的加速,高阳纺织品供应链的重要性日益凸显,本篇文章将围绕高阳纺织品供应链展开讨论,通过英文口语化的方式介绍其运作模式、案例分析以及未来发展趋势。

高阳纺织品供应链运作模式

采购环节

在采购环节,高阳纺织品供应链注重原材料的采购质量和来源的稳定性,通过与多家优质供应商建立长期合作关系,确保原材料的质量和供应的稳定性,采用先进的供应链管理系统,实时监控原材料的采购情况,确保供应链的顺畅运行。

生产环节

在生产环节,高阳纺织品供应链注重生产过程的精细化管理,采用先进的生产设备和技术,提高生产效率和质量,加强生产过程中的质量控制和安全管理,确保产品的质量和安全,通过与下游客户建立紧密的合作关系,实现产品的定制化和个性化生产。

物流环节

在物流环节,高阳纺织品供应链注重物流效率和服务质量,采用先进的物流管理系统,实现物流信息的实时更新和共享,加强物流过程中的安全管理和质量控制,确保物流环节的顺畅运行,通过建立完善的仓储和配送体系,提高物流效率和服务质量。

案例分析

以某知名纺织品企业为例,其高阳纺织品供应链的成功案例如下:

采购策略

该企业注重与优质供应商建立长期合作关系,确保原材料的质量和供应的稳定性,采用先进的供应链管理系统,实时监控原材料的采购情况,确保供应链的顺畅运行,该企业还注重与下游客户的紧密合作,实现产品的定制化和个性化生产。

生产过程管理

该企业在生产过程中注重精细化管理,采用先进的生产设备和技术,提高生产效率和质量,加强生产过程中的质量控制和安全管理,确保产品质量符合国家标准和客户要求,该企业还注重环保和可持续发展,采用环保材料和生产工艺,降低生产成本和环境影响。

物流环节优化

该企业在物流环节注重物流效率和服务质量,采用先进的物流管理系统,实现物流信息的实时更新和共享,加强物流过程中的安全管理和质量控制,确保物流环节的顺畅运行,该企业还建立了完善的仓储和配送体系,提高物流效率和服务质量,通过优化物流环节,降低运输成本和时间成本,提高企业的竞争力。

未来发展趋势

随着全球化和互联网技术的不断发展,高阳纺织品供应链将迎来以下发展趋势:

数字化和智能化发展

数字化和智能化是未来纺织品供应链的发展趋势,通过采用大数据、人工智能等技术手段,实现供应链的智能化管理和优化,通过大数据分析市场需求和供应情况,优化生产计划和库存管理;通过人工智能技术实现自动化生产线和智能仓储管理。

绿色环保发展

随着环保意识的不断提高,绿色环保将成为未来纺织品供应链的重要发展方向,企业将更加注重环保材料和生产工艺的选择,降低生产成本和环境影响,加强环保法规的执行力度,推动绿色供应链的发展。

全球化发展

随着全球化的加速,高阳纺织品供应链将更加注重全球化发展,企业将更加注重国际市场的开拓和合作,实现产品的全球销售和品牌建设,加强与国际先进企业的合作和交流,引进先进的管理经验和技术手段。

高阳纺织品供应链是现代企业发展的重要支撑之一,通过优化采购、生产、物流等环节,提高供应链的效率和竞争力,注重数字化、智能化、绿色环保等发展趋势,推动供应链的发展和创新,高阳纺织品供应链将继续发挥重要作用,为企业的可持续发展提供有力支持。

Articles related to the knowledge points of this article:

The Story of Xiao Qiu Textile Shop