The Fabric of Success:A Guide to Tailoring the Perfect End Product

"The Fabric of Success: A Guide to Tailoring the Perfect End Product" is a comprehensive guide that delves into the intricate process of crafting a successful product. The book emphasizes the importance of understanding the end goal and tailoring the product accordingly. It covers various aspects such as market research, product design, manufacturing processes, quality control, and marketing strategies.,The author provides practical tips on how to identify the target audience, create an effective brand identity, and develop a unique selling proposition. They also offer insights on how to optimize the product's features and benefits to stand out in a competitive market.,Furthermore, the book highlights the importance of collaboration between designers, engineers, and marketers to ensure that the product aligns with customer needs and expectations. It also emphasizes the need for continuous improvement and innovation to stay ahead of the competition.,Overall, "The Fabric of Success" is a valuable resource for anyone looking to create a successful product that meets the demands of their customers.

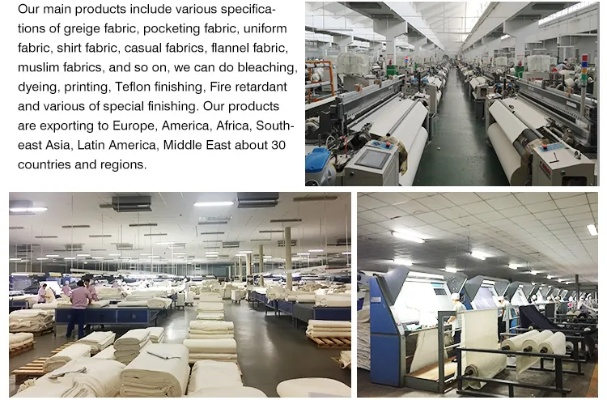

Introduction: In the world of textiles, every inch of fabric is a reflection of its journey from raw materials to finished products. From the intricate designs woven into yarns to the final touches applied to garments, every step in the manufacturing process plays a crucial role in determining the quality and end result of a textile product. In this article, we will explore the various stages of the textile industry, from raw material procurement to final product distribution, and how these elements come together to create the perfect end product.

Raw Material Procurement: The foundation of any textile production lies in the procurement of high-quality raw materials. These materials include cotton, polyester, wool, silk, and many more. To ensure that the right materials are sourced, manufacturers must invest in advanced technologies such as sensors and machine vision systems that can detect defects in the fibers and prevent contamination. Additionally, they must adhere to strict environmental regulations and ethical standards when sourcing materials, ensuring that they are sustainably sourced and do not harm the planet or human health.

Manufacturing Processes: Once the raw materials have been procured, they enter the manufacturing processes. Here, the most crucial factor is the skill and expertise of the craftsmen and women who work in the textile industry. They use specialized machinery such as knitting machines, sewing machines, and dyeing facilities to transform the raw materials into finished products. The quality control measures employed during this stage are essential to ensure that each piece meets the highest standards of quality and durability.

Design and Pattern Making: Before the fabric even begins to be woven or knitted, designers must create detailed patterns and sketches that outline the shape, size, and style of the final product. These patterns are then translated into digital files that are used by pattern makers to create accurate templates for the fabric. The accuracy of these templates is critical, as it affects the quality and consistency of the final product.

Weaving and Knitting: Once the patterns have been created and approved, the fabric begins to be woven or knitted. This involves using specialized machinery to interlock the threads in a particular pattern. The quality of the weaving or knitting process is determined by several factors, including the skill of the craftsmen and women involved, the quality of the machinery used, and the attention paid to detail.

Dyeing and Printing: After the fabric has been woven or knitted, it undergoes further processing before being dyed or printed. This stage involves applying color to the fabric using dyes or printing techniques that impart a unique texture and pattern. The quality of this stage is determined by the precision with which colors are applied and the attention paid to detail.

Quality Control: Throughout the entire manufacturing process, quality control measures are implemented to ensure that each piece meets the highest standards of quality and durability. This includes regular inspections of the finished product by trained personnel, as well as testing for specific properties such as strength, softness, and washability.

Packaging and Shipping: Finally, once the product has passed all quality control checks, it is packaged and shipped to its final destination. The packaging materials used should be durable and protect the product from damage during transportation. Additionally, proper shipping methods should be chosen to minimize the risk of breakage or loss during transit.

Conclusion: The textile industry is a complex and multifaceted industry that demands meticulous attention to detail and exceptional craftsmanship. From raw material procurement to packaging and shipping, every aspect plays a crucial role in creating the perfect end product. By following best practices and adhering to stringent quality control measures, manufacturers can ensure that their products meet the highest standards of excellence and stand out in a competitive market. As we continue to advance in technology and innovation, the textile industry will undoubtedly continue to evolve and adapt to meet the ever-changing needs of consumers around the world.

在繁忙的纺织厂中,打尾环节是生产过程中的重要一环,它不仅关乎产品质量,更是企业经济效益的体现,本文将围绕纺织厂打尾的主题,通过英文口语化的方式展开讨论。

纺织厂打尾工艺概述

打尾流程

纺织厂的打尾工艺包括原料准备、织造、染整和整理等多个环节,在原料准备阶段,主要进行纤维的选择和预处理;在织造过程中,根据设计要求进行织造;染整环节则通过染色和整理,使产品达到特定的外观和性能要求;在整理阶段,对产品进行最后的修饰和整理。

打尾工艺特点

纺织厂的打尾工艺具有以下特点:

(1)环保性:采用环保染料和工艺,减少对环境的污染。

(2)高效性:采用先进的织造和染整技术,提高生产效率。

(3)个性化:根据客户需求定制产品,满足不同市场和客户的需求。

案例分析

以某知名纺织厂为例,其打尾工艺的成功实践及其背后的原因。

某纺织厂在打尾环节采用了先进的织造技术,结合环保理念,成功生产出高质量的产品,该厂注重技术创新和工艺优化,不断提高生产效率和产品质量,该厂还注重与客户沟通,根据客户需求定制产品,满足不同市场和客户的需求,这种灵活的生产模式使得该厂在市场上具有较高的竞争力。

纺织厂打尾实践与探讨

-

实践方面:纺织厂在打尾环节采取了多种措施,提高生产效率和产品质量,采用自动化设备提高生产效率,优化工艺流程减少浪费;加强员工培训,提高员工技能水平,该厂还注重环保理念的应用,采用环保染料和工艺,减少对环境的污染。

-

探讨方面:在纺织厂打尾实践中,我们还可以从以下几个方面进行探讨:

(1)技术创新:继续研发新的纺织技术,提高生产效率和产品质量,关注行业发展趋势,不断更新设备和工艺。

(2)环保理念:在打尾环节中融入环保理念,推动企业可持续发展,加强与政府和相关机构的合作,争取政策支持和资金支持。

(3)客户需求:深入了解客户需求,根据客户需求定制产品,加强与客户的沟通,提高客户满意度和忠诚度。

纺织厂打尾是生产过程中的重要环节,它不仅关乎产品质量,更是企业经济效益的体现,在纺织厂打尾实践中,我们应该注重技术创新、环保理念和客户需求等方面的工作,我们还应该加强与政府和相关机构的合作,争取政策支持和资金支持,推动企业可持续发展,通过不断的努力和实践,我们相信纺织厂的打尾环节将会越来越好。

Articles related to the knowledge points of this article:

The Story of Yingxiang Textile Factory

The Journey of Innovation at Jining JiaXiang Textile Factory