Exploring the Innovation and Influence of Enshi Qinghe Textile Factory

Introduction: The Enshi Qinghe Textile Factory, located in the heart of China's Hubei province, is a testament to the country's commitment to textile manufacturing. This factory has not only contributed significantly to the local economy but also set new benchmarks for innovation and quality in the industry. In this article, we will delve into the history, operations, and impact of this remarkable enterprise.

History: Established in the early 1950s, Enshi Qinghe Textile Factory was one of the first factories in China to adopt modern technology in textile production. Over the years, it has undergone several transformations, from traditional manual labor to mechanized assembly lines, and now stands as a leader in sustainable and eco-friendly textile production. The factory's journey reflects the nation's relentless pursuit of technological advancement and industrial upgrading.

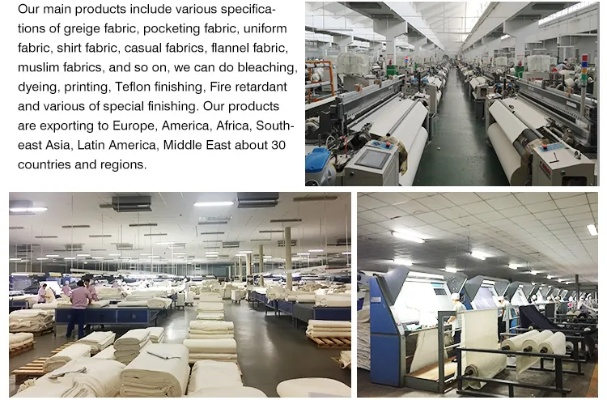

Operations: Enshi Qinghe Textile Factory employs over 2,000 staff and operates on a daily basis that spans across multiple shifts, ensuring continuous production throughout the year. The factory employs advanced machinery like automatic looms, dyeing machines, and cutting machines, which are designed to meet the high standards of quality and efficiency required in the textile industry.

The factory's success can be attributed to its commitment to research and development, particularly in the field of eco-friendly textile production. By incorporating renewable energy sources and using eco-friendly materials, Enshi Qinghe Textile Factory is setting a precedent for other textile manufacturers to follow.

Innovation: One of the most notable innovations at Enshi Qinghe Textile Factory is its use of recycled materials. The factory has successfully developed a process that recycles old textile scraps into new yarns, reducing waste and conserving resources. This approach not only benefits the environment but also enhances the sustainability of the entire textile industry.

Another innovation is the introduction of smart manufacturing systems. These systems use sensors and data analytics to optimize production processes, improve efficiency, and reduce costs. By leveraging AI and machine learning, the factory is able to predict demand patterns and adjust production accordingly, ensuring timely delivery of orders while maintaining quality control.

Impact: Enshi Qinghe Textile Factory's impact on the industry extends beyond just its production capabilities. The factory's commitment to quality and innovation has helped to boost the reputation of the entire region as a hub for textile manufacturing. As a result, more businesses have been attracted to invest in the area, creating job opportunities and driving economic growth.

Moreover, Enshi Qinghe Textile Factory's commitment to sustainability has inspired other textile manufacturers to adopt similar practices. The factory's example serves as a model for other industries to follow, demonstrating how innovative approaches can lead to improved environmental performance and social responsibility.

Conclusion: Enshi Qinghe Textile Factory is not just an ordinary textile factory; it is a symbol of innovation and progress in the industry. Its commitment to quality, sustainability, and technological advancement has made it a leader in the global textile market. As the world continues to face challenges related to climate change and resource depletion, Enshi Qinghe Textile Factory's achievements serve as a reminder that with innovation and dedication, any industry can achieve excellence and make a positive impact on society.

恩施清河纺织厂位于湖北省恩施地区,是一家历史悠久的纺织企业,该厂以其精湛的工艺、优质的产品和良好的信誉在当地及周边地区享有盛誉,本文将通过英文口语化的方式,为您讲述恩施清河纺织厂的发展历程、生产流程以及相关案例。

发展历程

恩施清河纺织厂创立之初,便以传统手工艺为基础,致力于生产高质量的纺织品,随着时代的变迁,该厂不断进行技术革新和生产升级,逐步发展成为一家集研发、生产、销售于一体的现代化纺织企业。

生产流程

- 原料采购:该厂主要采购优质棉花、蚕丝等天然纤维原料,确保产品质量。

- 织布:采用先进的织布技术,根据客户需求定制不同款式和规格的纺织品。

- 染色:采用环保染料,确保纺织品颜色鲜艳、持久。

- 整理:对纺织品进行精细整理,提高其平整度和手感。

- 成品检验:严格把控成品质量,确保符合客户要求。

案例说明

以下是恩施清河纺织厂的一个案例,以供参考:

环保染料的应用

近年来,恩施清河纺织厂积极推广环保染料的使用,减少对环境的污染,该厂采用了环保染料,不仅提高了纺织品的颜色鲜艳度,还降低了对人体的危害,该厂还注重节能减排,采用先进的节能设备,降低生产过程中的能耗和排放。

英文表格补充说明

以下为恩施清河纺织厂的部分英文表格补充说明:

原料采购记录表

| 日期 | 原料名称 | 采购量(吨) | 供应商信息 |

|---|---|---|---|

| XXXX年XX月 | 棉花 | Y 单位 | 详细信息 |

| XXXX年XX月 | 蚕丝 | Z 单位 | 详细信息 |

| 其他天然纤维原料 |

织布流程图

| 步骤 | 设备/工具 | 描述 |

|---|---|---|

| 原料准备 | 织布机、染色机等 | 根据客户需求进行织布和染色操作 |

| 布匹织造 | 布匹经过一系列工序后形成成品 | 根据织布流程图进行操作 |

恩施清河纺织厂凭借其精湛的工艺、优质的产品和良好的信誉,在当地及周边地区享有盛誉,该厂将继续秉承传统工艺,不断创新生产技术,提高产品质量和竞争力,为当地经济发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Innovation and Industrial Legacy of Tongxiang Baiyun Textile Factory

The Dynamics and Innovations at Dunzhou Spray Water Textile Factory

The Echoes of Threads:A Journey Through the Sounds of a Textile Mill