The Fabric of Innovation at Haian Airflow Textile Factory

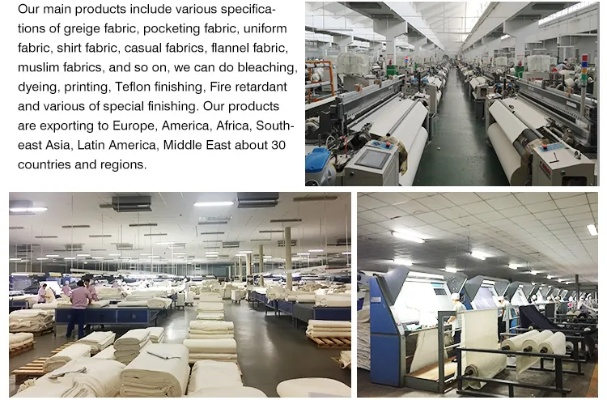

Haian Airflow Textile Factory is a leading manufacturer of innovative textile products in China. The factory's success can be attributed to its commitment to innovation and continuous improvement. The factory has invested heavily in research and development, and has developed a range of new products that meet the needs of customers around the world.,One of the key factors in Haian Airflow's success is its focus on customer satisfaction. The factory understands that customers want high-quality products at competitive prices, and it works tirelessly to deliver exactly what they need. This approach has earned the factory a reputation for reliability and trustworthiness among its customers.,Another important factor in Haian Airflow's success is its ability to adapt to changing market conditions. The factory is constantly monitoring industry trends and adjusting its strategies accordingly. This flexibility allows it to stay ahead of the competition and capitalize on new opportunities.,Overall, Haian Airflow Textile Factory's commitment to innovation and customer satisfaction has helped it become a leading player in the textile industry. Its dedication to quality and adaptability have positioned it as a trusted partner for businesses looking for high-performance textile solutions.

Introduction: In the realm of textile manufacturing, Hai'an Airflow Textile Factory stands as a beacon of innovation and excellence. With its commitment to crafting high-quality fabrics that meet the demands of today's fast-paced world, this factory has become a beacon of industry innovators, setting new standards for the industry. In this article, we will delve into the fascinating world of Hai'an Airflow Textile Factory, exploring its unique approach to textile production, its innovative technologies, and how it has revolutionized the textile industry.

Production Process: At Hai'an Airflow Textile Factory, every step of the production process is meticulously designed to ensure the highest quality end product. From the initial stages of raw material procurement to the final assembly line, each stage is carefully monitored to guarantee consistent results.

-

Raw Materials: Hai'an Airflow Textile Factory sources its raw materials from reputable suppliers who adhere to strict environmental and ethical standards. The selection process involves rigorous inspections to ensure that only the finest and most sustainable materials are used.

-

Pre-treatment: Before any processing begins, the raw materials undergo a thorough pre-treatment process. This includes decontamination, sterilization, and conditioning to ensure that the fabric is ready for the next steps in the production process.

-

Weaving: The fabric is then woven using state-of-the-art machinery. The weaving process is meticulously controlled, with each thread being precisely placed to create a seamless and durable fabric.

-

Dyeing: Once the fabric is woven, it undergoes dyeing to add color and texture. The dyeing process is done using eco-friendly and non-toxic dyes that do not harm the environment or human health.

-

Finishing: After dyeing, the fabric undergoes a series of finishing processes, including washing, drying, and pressing. These processes help to enhance the fabric's durability, softness, and overall appearance.

-

Packaging: Finally, the finished fabric is packaged in eco-friendly packaging materials to ensure that it reaches its destination in perfect condition.

Technology: At Hai'an Airflow Textile Factory, technology plays a crucial role in driving innovation and improving efficiency. The factory utilizes cutting-edge technology to streamline the production process and enhance product quality.

-

Automation: The factory employs advanced automation systems to ensure that every step of the production process runs smoothly. This includes robotic weaving machines, automated dyeing machines, and integrated control systems that monitor the entire production process.

-

Digital Control Systems: The use of digital control systems ensures that the production process is optimized for maximum efficiency and productivity. These systems allow for precise adjustments to be made to the production parameters, resulting in consistently high-quality products.

-

Green Technology: To reduce environmental impact, the factory incorporates green technology into its production processes. This includes the use of renewable energy sources such as solar power and wind power, as well as the implementation of waste reduction strategies.

Case Study: One example of how Hai'an Airflow Textile Factory has revolutionized the textile industry is through its successful development of a high-performance sportswear fabric. The company's team of engineers developed a special blend of fibers that combines strength, flexibility, and breathability. By utilizing this innovative technology, the factory was able to produce a sportswear fabric that not only met but exceeded the performance standards set by major sporting organizations.

Conclusion: Hai'an Airflow Textile Factory's commitment to innovation and sustainability sets it apart from other textile manufacturers. Through its meticulous production processes, cutting-edge technology, and dedication to environmental responsibility, the factory has become a leader in the textile industry. As more companies seek to innovate and improve their products, Hai'an Airflow Textile Factory's success story serves as an inspiration for future textile manufacturers to follow.

背景介绍

海安气流纺织厂位于江苏省海安市,是一家历史悠久且技术先进的纺织企业,该厂专注于各类纺织品的生产与销售,以其精湛的工艺、优质的产品和良好的信誉赢得了广大客户的信赖。

企业概况

- 企业规模:该厂拥有现代化的生产线和先进的设备,年生产能力超过千万件纺织品。

- 行业地位:作为当地纺织行业的领军企业,海安气流纺织厂在国内外市场上享有较高的声誉。

- 企业文化:注重创新、质量和服务,致力于为客户提供高品质的产品和服务。

主要产品与服务

- 主要产品:包括棉布、丝绸、麻布等各类纺织品,以及各种功能性面料。

- 服务项目:提供定制化生产服务、技术支持、售后服务等。

生产工艺与设备

- 生产工艺:采用先进的纺织技术,包括织造、染整、印花等工序。

- 设备情况:拥有先进的生产设备,包括全自动织机、染整设备、印花机等。

案例分析

以下是海安气流纺织厂的一个案例说明,以供参考:

高端丝绸面料生产

某客户需要生产一款高端丝绸面料,该厂采用了先进的丝绸纺织技术,成功生产出一款高品质的丝绸面料,该面料具有轻薄柔软、色泽鲜艳的特点,深受客户好评,该厂的精湛工艺和优质产品得到了客户的认可和赞誉。

企业优势与特色

- 企业优势:拥有先进的生产设备和技术,拥有专业的研发团队和完善的售后服务体系。

- 企业特色:注重环保、节能、低碳,采用绿色生产方式,致力于为客户提供绿色、健康的产品。

海安气流纺织厂将继续秉承“质量第一、客户至上”的原则,不断加强技术研发和设备升级,提高生产效率和产品质量,为客户提供更加优质的产品和服务,该厂还将积极拓展国内外市场,提高品牌知名度和影响力。

Articles related to the knowledge points of this article:

High Qing Textile Factorys History

The Noisy Background of a Textile Factory