Textile Dyeing Quality Inspection Methodology

: Textile Dyeing Quality Inspection Methodology,Abstract:,This paper presents a comprehensive methodology for the quality inspection of textile dyeing processes. The study emphasizes on the importance of colorfastness, uniformity, and washability in assessing the performance of dyed textiles. Various testing methods such as spectrophotometry, colorimetric analysis, and visual assessment are employed to evaluate these properties. Additionally, the study discusses the application of advanced techniques like digital imaging and computer-aided colorimetry for enhancing the precision and efficiency of the inspection process. The findings highlight the need for continuous monitoring and improvement in the quality control measures to ensure consistent product standards. Overall, this research provides valuable insights into the effective implementation of quality inspection methodologies in textile dyeing operations.

Introduction: In the textile industry, ensuring the quality and safety of dyes used in manufacturing is crucial for maintaining consumer confidence and complying with regulatory standards. Dyeing methods can be complex, involving multiple steps from preparation to application, and require precise control to prevent color shifts or undesirable side effects. This article will discuss a comprehensive approach to textile dyeing quality inspection using a standardized methodology known as "Dyeing Quality Inspection."

Standardization: The first step in any quality inspection process is establishing a set of standards that align with international regulations and industry best practices. For textile dyeing, these standards may include specific color requirements, dye concentration limits, and maximum exposure times. It's important to ensure that all dyed products meet these criteria to avoid health hazards and legal issues.

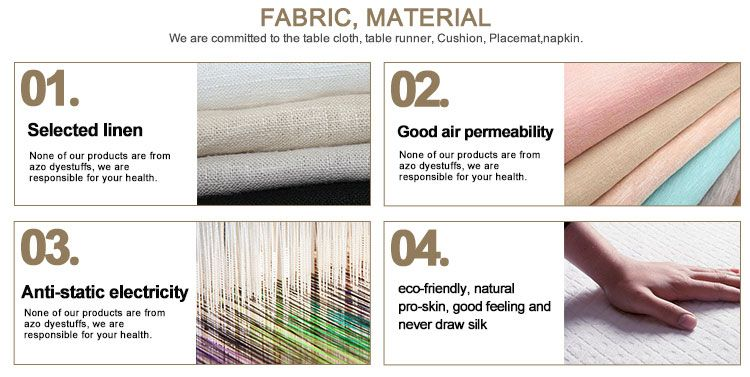

Pre-Treatment: Before dyeing, it's essential to pre-treat the fabric to remove any existing contaminants or oils that could interfere with the dye's adhesion or migration during the dyeing process. This step involves cleaning the fabric with detergents and solvents designed to dissolve impurities without damaging the fiber structure.

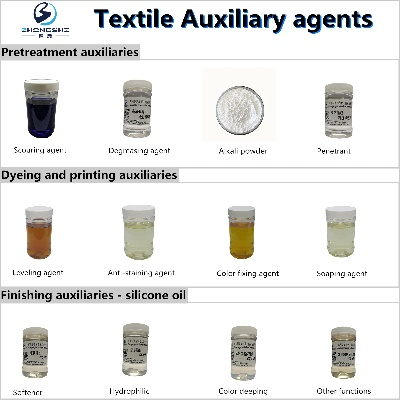

Dyeing Process Control: Once the fabric is ready for dyeing, monitoring the dye bath's temperature, pH, and other variables is critical to achieving consistent results. The dye bath should be monitored regularly to ensure that the dye is evenly distributed throughout the fabric, and that the color intensity and uniformity are within acceptable ranges.

Post-Dyeing Treatment: After dyeing, the fabric must undergo post-treatment to remove excess dye and stabilize the color. This may involve washing with special detergents, air drying, or using heat treatment methods like steaming or autoclaving. The goal is to minimize any residual colorants that could affect the final product's appearance or performance.

Quality Checklist: To ensure consistency and accuracy in the dyeing process, a quality checklist should be developed and followed meticulously. This checklist should include visual inspections for color uniformity, thickness uniformity, and overall appearance; weight measurements for density; and tests for shrinkage and strength retention.

Sample Collection: It's important to collect samples from different stages of the dyeing process to assess the integrity of the dyed fabric. These samples should be representative of the entire batch and should be stored properly to maintain their condition.

Analysis Methods: Once the samples have been collected, they can be analyzed for various properties using standard analytical techniques such as spectrophotometry, colorimetry, and chromatography. These methods allow for accurate measurement of dye concentration, color intensity, and other key parameters.

Data Analysis: The data gathered from the analysis methods should be thoroughly analyzed to identify any deviations from the established standards. Any discrepancies should be investigated further to determine the cause and take appropriate corrective actions.

Case Study: One example of a successful textile dyeing quality inspection is provided by the company ABC Ltd. They use a standardized protocol for every dyeing process, including pre-treatment, dye bath monitoring, post-treatment, and sample collection. By implementing this method, they were able to consistently produce high-quality dyed fabrics that met all customer specifications and regulatory requirements.

Conclusion: Textile dyeing quality inspection is an essential step in the production process that ensures the end product meets industry standards and consumer expectations. By following a standardized methodology, companies can reduce errors, improve efficiency, and enhance product reliability. As technology advances, new tools and techniques will continue to emerge, making it even more critical for textile manufacturers to stay up-to-date with the latest trends and standards.

随着纺织品行业的快速发展,纺织品的质量和安全性越来越受到人们的关注,丁酮作为一种常见的有机溶剂,广泛应用于纺织品的加工过程中,为了确保纺织品的质量和安全,对纺织品中的丁酮含量进行检测是必要的,本文将介绍纺织品丁酮检测的方法,并结合案例说明进行详细阐述。

纺织品丁酮检测方法

检测原理

纺织品丁酮检测主要采用化学分析法,通过测定纺织品中丁酮的含量,来判断其是否符合相关标准,该方法主要基于丁酮与特定试剂反应后生成有色物质的原理。

检测步骤

(1)样品准备:采集待检测的纺织品样品。 (2)试剂准备:准备丁酮检测试剂,确保试剂的纯度和有效性。 (3)样品处理:将样品在适宜条件下进行预处理,如溶解、稀释等。 (4)检测:使用特定的检测仪器或方法进行丁酮含量的测定。 (5)结果分析:根据检测结果,判断纺织品中丁酮的含量是否符合标准。

检测方法举例

(1)色谱法检测:采用高效液相色谱法或气相色谱法等色谱技术,对纺织品中的丁酮进行分离和测定,该方法具有较高的灵敏度和准确性,适用于大规模的纺织品检测。

(2)光谱法检测:利用光谱技术对纺织品中的丁酮进行定性或定量分析,紫外可见光谱法、红外光谱法等,可以根据丁酮的特征吸收峰或发射波长进行检测。

案例说明

某纺织企业纺织品丁酮检测案例

某纺织企业为了确保纺织品的质量和安全,对其生产的纺织品进行了丁酮含量检测,该企业采用了色谱法进行检测,具体步骤如下:

(1)样品采集:从生产线上采集待检测的纺织品样品。 (2)试剂准备:选择合适的丁酮检测试剂,确保试剂的纯度和有效性。 (3)样品处理:将样品在适宜条件下进行预处理,如溶解、稀释等。 (4)色谱分析:使用色谱仪对样品进行分离和测定,得到准确的丁酮含量数据。 (5)结果分析:经过色谱分析,该纺织品的丁酮含量符合相关标准,质量可靠。

纺织品质量抽检案例

为了加强对纺织品质量的监管,某地区开展了纺织品质量抽检工作,抽检过程中,采用了光谱法进行检测,具体步骤如下:

(1)样品采集:从市场上采集符合标准的纺织品样品。 (2)光谱分析:使用光谱分析仪器对样品进行定性或定量分析,判断其是否符合相关标准。 (3)结果判定:根据光谱分析结果,判定样品是否合格,如果样品符合标准,则可视为合格产品;如果不符合标准,则需进一步进行深入检测或采取相应措施。

纺织品丁酮检测方法主要包括化学分析法、色谱法和光谱法等,在实际应用中,应根据待测样品的性质和要求选择合适的检测方法,为了提高检测的准确性和可靠性,还需注意以下几点:

- 选择合格的试剂和设备;

- 保证样品处理的准确性和可靠性;

- 遵循相关标准和操作规程;

- 结合实际案例进行分析和说明。

纺织品丁酮检测方法对于保障纺织品的质量和安全具有重要意义,在实际应用中,应加强检测方法的研发和应用,提高检测的准确性和可靠性,为纺织品的生产和销售提供有力保障。

Articles related to the knowledge points of this article:

Silk Pillowcases and Bedding:The Art of Comfort for a Better Nights Sleep

Export Tax Rates in Korea A Guide to Ensure Compliance and Maximize Profits

A Profile of PJSH Textiles The Fabric of Modern Elegance

The Unparalleled Luxury of 腾翔印花纺织品

Kitchen Textiles and Their Impact on the Cooking Experience

Exploring the Future of Quality:The Story of Qianzhuang Textiles Company