Recycling and Reusing Textiles:A Greener Future for the Industry

: "Recycling and Reusing Textiles: A Greener Future for the Industry",Abstract:,The textile industry is a major contributor to environmental pollution, with textile waste posing significant challenges in landfill management and resource depletion. This paper explores the potential of recycling and reusing textiles through various strategies, highlighting the benefits of greener practices that can significantly reduce waste generation and promote sustainable development. The adoption of innovative technologies and processes, such as upcycling, biodegradable materials, and circular economy principles, can transform the textile industry into a more eco-friendly and economically viable sector. The research emphasizes the importance of government policies, corporate responsibility, and public awareness in driving the transition towards a circular economy. By embracing sustainable practices, the textile industry can contribute to a cleaner, healthier planet while also ensuring its long-term viability and competitiveness.

本文目录导读:

- Sorting

- Cleaning

- Shredding

- Processing

- Case Study: Textile Recycling in the Fashion Industry

- Challenges and Opportunities

Textile waste, a ubiquitous byproduct of modern manufacturing, poses a significant environmental challenge. With the growing demand for sustainable practices, the textile recycling industry is gaining momentum worldwide. This sector not only reduces the amount of textile waste that ends up in landfills but also contributes to a healthier planet by reducing greenhouse gas emissions and minimizing water pollution.

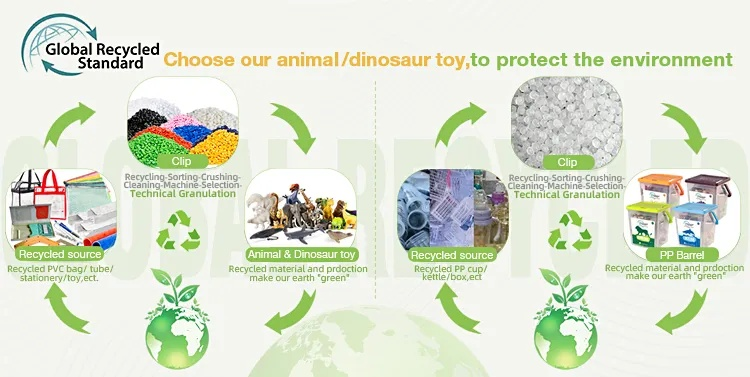

The textile recycling process involves several stages: sorting, cleaning, shredding, and processing. The goal is to transform these materials into new products or raw materials for further use. Here's how this process works, along with some key points to consider when implementing textile recycling systems.

Sorting

Before any recycling begins, it's crucial to sort the textile waste into different categories. This includes separating synthetic fibers (like polyester and nylon) from natural fibers (like cotton and wool). Different types of textiles can then be processed accordingly.

| Category | Description |

|---|---|

| Synthetic Fibers | Includes polyester, nylon, acrylic, and more |

| Natural Fibers | Includes cotton, linen, hemp, and wool |

| Other Materials | Includes plastic, metal, and glass |

Cleaning

Once sorted, the textile waste undergoes cleaning to remove impurities and contaminants. This step is critical to ensure that the subsequent shredding process is effective.

Shredding

Shredding is the process of breaking down large textile pieces into small, manageable sizes. This allows for easier processing and ensures that the recycled materials meet quality standards.

| Size | Quality Standard |

|---|---|

| Small | Must pass through a screen |

| Medium | May be used as a filler material |

| Large | Not suitable for high-quality products |

Processing

After shredding, the textile waste is processed into various forms such as yarn, fabric, and other materials. These are then sold to manufacturers who use them to create new products.

Case Study: Textile Recycling in the Fashion Industry

One example of successful textile recycling in the fashion industry is the "upcycling" movement. This practice involves repurposing old clothes into new items like furniture, accessories, or even clothing. By using upcycled textiles, fashion brands not only reduce their environmental impact but also offer unique designs that appeal to consumers.

In addition to upcycling, many fashion companies are investing in textile recycling technologies to further streamline their operations. For example, some have implemented advanced sorting machines that can separate different types of textiles with high precision. Others have developed automated shredding systems that can process large volumes of textile waste efficiently.

Challenges and Opportunities

While textile recycling offers numerous benefits, there are still challenges to overcome. One major issue is the lack of awareness among consumers about the importance of textile recycling. To address this, companies can promote education campaigns and partnerships with local schools and community groups to raise awareness about the benefits of textile recycling.

Another challenge is the cost of implementing efficient textile recycling systems. However, as technology advances and economies of scale become more prevalent, the costs associated with textile recycling will likely decrease over time.

On the bright side, the textile recycling industry presents numerous opportunities for growth and innovation. As consumer demand for sustainable products increases, textile recycling will become an increasingly important part of the global economy. Companies that invest in this sector now stand to benefit from increased market demand and a reputation for sustainability in the years to come.

In conclusion, textile recycling is not just a solution to waste management; it's a strategic move towards a greener future. By implementing effective sorting, cleaning, shredding, and processing processes, we can turn textile waste into valuable resources that support sustainable industries. As we continue to explore innovative solutions, the textile recycling industry has the potential to play a vital role in mitigating environmental challenges while creating new opportunities for economic growth and social responsibility.

纺织品回收利用设备概述

随着环保意识的日益增强,纺织品回收利用设备在纺织行业中的重要性日益凸显,这些设备不仅有助于减少环境污染,还能有效利用废旧纺织品资源,推动循环经济的发展,本文将详细介绍纺织品回收利用设备的类型、功能及其在实践中的应用案例。

设备类型及功能

机械式回收设备

机械式回收设备是一种集成了多种功能的设备,主要用于废旧纺织品的高效回收,该设备通过机械动作将纺织品从各种材料中分离出来,包括棉、麻、丝、毛等,设备内部设有精密的筛网和分离装置,能够精确地将不同材质的纺织品分离出来,设备还配备了自动称重系统和电子记录系统,实现了废旧纺织品的高效、自动化处理。

生物降解材料再生设备

生物降解材料再生设备主要用于处理可生物降解的纺织品,如塑料袋、布等,该设备采用了先进的生物降解技术,能够将废旧纺织品转化为再生纤维或生物塑料,设备内部设有高温高压反应器,能够使废旧纺织品中的化学成分发生化学反应,生成新的生物材料,设备还配备了自动检测系统和智能控制系统,实现了废旧纺织品的高效、智能化处理。

实践案例分析

某纺织企业采用机械式回收设备处理废旧纺织品

某纺织企业为了减少环境污染,提高资源利用率,采用了机械式回收设备处理废旧纺织品,该企业通过与专业厂家合作,购买了先进的机械式回收设备,实现了废旧纺织品的快速、高效回收,设备运行稳定,处理效率高,大大降低了企业的环境污染和资源浪费,该企业还通过与相关行业协会合作,推广了废旧纺织品回收利用的知识和技术,提高了企业的社会影响力。

某生物降解材料再生设备处理塑料袋等可生物降解材料

某生物降解材料再生设备处理塑料袋等可生物降解材料时,采用了先进的生物降解技术,该设备能够高效地将废旧塑料袋转化为再生纤维或生物塑料,实现了废旧纺织品的循环利用,该设备的智能化控制系统能够实时监测和处理废旧纺织品的数量和质量,保证了再生纤维的质量和产量,该企业还通过开展宣传活动,提高了废旧纺织品回收利用的社会认知度。

技术应用与展望

纺织品回收利用设备的研发和应用在纺织行业中的发展前景广阔,随着科技的不断发展,新型的设备和技术不断涌现,为废旧纺织品的高效回收利用提供了更多的可能性,政府对环保和循环经济的重视也为纺织品回收利用设备的研发和应用提供了更好的政策支持,纺织品回收利用设备将更加智能化、高效化、环保化,为纺织行业的发展和社会的可持续发展做出更大的贡献。

纺织品回收利用设备的研发和应用对于推动纺织行业的发展和社会的可持续发展具有重要意义,在未来的发展中,我们需要继续加强设备的研发和应用,提高设备的性能和效率,同时还需要加强设备的环保性和可持续性,实现废旧纺织品的高效回收利用和可持续发展。

Articles related to the knowledge points of this article:

Top Picks for Shanghai Home Textile Essentials

The Ugandan Textile Market A Global Perspective and Regional Insights

A Comprehensive Overview of Textile Industry Knowledge Notes

Shanghai Jia Lan Textiles A Gateway to Luxury and Quality

Unveiling the Fabric of Success:A Strategic Guide for Textile Enterprises

EU Ban on Textile Exports:A Global Impact and Lessons Learnt