The Art of Preserving the Fabric:A Guide for Textile Workers

"The Art of Preserving the Fabric: A Guide for Textile Workers" is a comprehensive guide that provides essential knowledge and techniques for preserving the fabric of textiles. The guide covers various aspects such as the use of natural and synthetic fibers, dyeing processes, washing methods, and proper storage techniques. It emphasizes the importance of understanding the properties of different materials and using them appropriately to maintain their quality and durability.,The guide also includes practical tips on how to identify and repair damaged fabrics, as well as how to choose the right tools for the job. It offers advice on how to prevent fading and staining, as well as how to care for fabrics when they are not in use. Overall, "The Art of Preserving the Fabric" is a valuable resource for anyone who works with textiles, providing them with the knowledge and skills they need to keep their fabrics looking their best for years to come.

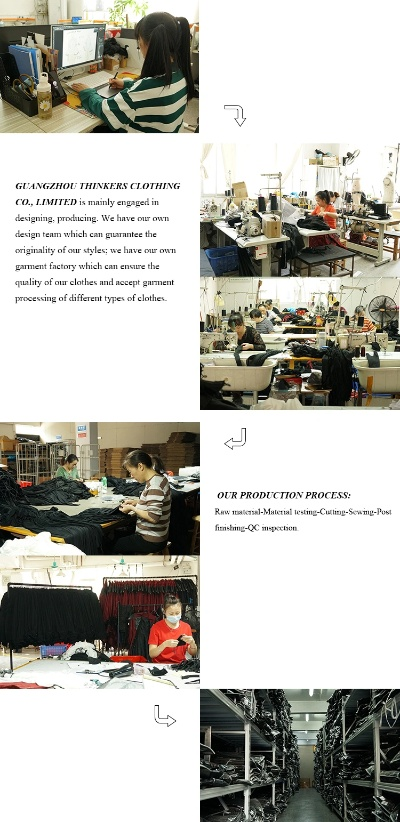

Introduction: In the world of textiles, the fabric is the heart of every garment, be it a cozy sweater or a sleek suit. It's no wonder then that maintaining its quality and integrity is paramount to the success of any textile factory. As a member of the maintenance team at a major textile plant, I have come to understand the importance of preserving the fabric through various methods, from regular inspections to preventive measures. In this guide, we will explore the intricacies of textile maintenance, including how to identify potential issues before they become major problems, what tools are essential for effective maintenance, and how to troubleshoot common problems. With these tips in hand, you can ensure that your fabric remains pristine, ensuring long-lasting results for both your customers and your factory's reputation.

Preventative Maintenance: Preventive maintenance is key to keeping your fabric in top condition. Here are some essential steps to follow:

-

Regular Inspections:

- Schedule regular checks with your machine's manufacturer to ensure everything is functioning correctly.

- Monitor the temperature and humidity levels in your storage area to prevent moisture damage.

- Inspect the machinery regularly for signs of wear and tear, such as rust or corrosion.

-

Cleaning and Lubrication:

- Regularly clean all moving parts of the machines to remove dirt and debris that could cause damage.

- Apply lubricants to all moving parts to ensure smooth operation and minimize friction.

-

Regular Maintenance Checklist:

- Keep a detailed checklist of all the machines and their parts, so you can quickly identify any issues.

- Follow the manufacturer's recommended maintenance schedule for each machine.

Tools and Equipment: To perform these tasks effectively, you'll need the right tools and equipment. Here's what you'll need:

-

Machinery:

- All the machinery used in the production process, including washing machines, dyeing machines, and finishing equipment.

- Tools like screwdrivers, wrenches, pliers, and adjustable wrench sets.

-

Cleaning Supplies:

- Detergents, solvents, and cleaning pads for machine parts.

- Scrubbers, brushes, and sponges for cleaning surfaces.

-

Lubricants:

- Greases and oils specifically designed for the machinery and parts.

- Liquids like water and detergents for cleaning purposes.

-

Inspection Tools:

- Magnets and metal detectors for detecting hidden metal pieces or particles.

- Wire brushes for removing embedded dirt or debris.

-

Maintenance Records:

- Keep track of all the maintenance activities performed on each machine using a maintenance logbook.

- This logbook will help you keep track of when each machine was last serviced and inspected.

Troubleshooting Common Problems: If something goes wrong during maintenance, it's important to know how to troubleshoot the problem. Here are some common issues and solutions:

-

Leaks or Drainage Issues:

- Check for any leaks around the machinery or hoses.

- Ensure that all drains are clear and not clogged.

-

Faulty Machinery:

- If a machine is not working properly, consult the manual for troubleshooting steps.

- If the issue persists, contact the manufacturer's support team for further assistance.

-

Poor Quality of Fabric:

- Check the dye bath or printing process for any irregularities.

- Adjust the settings on the machinery if necessary to achieve consistent results.

-

Electrical Issues:

- If there are any electrical faults, turn off the power supply immediately.

- Call an electrician for professional repairs if the issue cannot be resolved by yourself.

Case Study: Let's take a look at a real-life example where our textile worker faced a challenging situation while performing maintenance on a high-demand textile machine. The machine was producing defective fabric due to a faulty heating element. Without proper knowledge or tools, the worker had no idea how to fix this issue. But with the right tools and expertise, they were able to diagnose the problem and replace the heating element, restoring the machine to its original state. By following the preventative maintenance checklist and troubleshooting techniques outlined above, they were able to prevent similar issues from occurring in the future.

Conclusion: As we wrap up our discussion on textile maintenance, it's crucial to remember that investing in regular inspections, thorough cleaning, and preventative measures will go a long way in ensuring the longevity of your fabric. By following the tips and tools outlined in this guide, you can maintain your fabric to its best possible condition, ensuring a successful outcome for both your customers and your factory. So, let's embrace the art of preserving the fabric together and continue to strive for excellence in our textile industry!

作为纺织厂的保修工,他们肩负着确保产品质量和客户满意度的重任,本文将围绕这一主题,通过口语化的英文表达,为您详细介绍纺织厂保修工的工作职责、工作内容以及案例分析。

工作职责与工作内容

纺织厂保修工主要负责纺织品的质量检测、问题产品的维修和客户投诉的处理,他们需要具备专业的技能和知识,能够准确判断问题所在,提供有效的解决方案。

(1)质量检测:负责纺织品的质量检测工作,确保产品符合相关标准和客户要求,他们需要使用专业的检测设备和方法,对纺织品进行全面检查,发现并记录潜在的质量问题。

(2)维修服务:对于发现的问题产品,他们需要迅速进行维修,这包括更换损坏的部件、修复损坏的工艺等,他们还需要与客户保持沟通,了解客户的需求和反馈,以便更好地满足客户需求。

(3)处理客户投诉:对于客户投诉的处理,他们需要保持耐心和细致,认真倾听客户的诉求,并尽快给出解决方案,他们还需要对投诉进行跟踪处理,确保问题得到妥善解决。

案例分析

以某纺织厂为例,该厂保修工在日常工作中遇到了以下案例:

客户投诉处理

某客户在购买纺织品后发现产品质量存在问题,向该厂保修工寻求帮助,保修工迅速响应,与客户沟通了解问题详情,经过仔细检查,发现是某个部件损坏导致产品质量下降,保修工立即联系供应商进行维修,并为客户提供维修后的样品测试,客户对维修结果表示满意,并给予了高度评价。

维修效率提升

为了提高维修效率,该纺织厂在保修工岗位上引入了先进的维修管理系统,通过使用该系统,保修工可以快速定位问题产品,并迅速进行维修,系统还可以自动记录维修过程和结果,为后续的维修工作提供参考,这一改进措施大大提高了维修效率,减少了客户等待时间。

案例说明

在纺织行业日益竞争的今天,提高产品质量和客户满意度已经成为纺织厂的重要任务,为了更好地履行这一职责,纺织厂在保修工岗位上采取了以下措施:

-

培训与教育:定期为保修工提供专业技能和知识培训,确保他们具备专业的技能和知识,加强对客户需求的了解和分析,以便更好地满足客户需求。

-

质量检测设备更新:引进先进的检测设备和技术,提高质量检测的准确性和效率,加强对检测结果的跟踪和分析,以便及时发现并解决潜在的质量问题。

-

维修管理系统升级:引入先进的维修管理系统,提高维修效率和质量,通过使用该系统,保修工可以快速定位问题产品,并迅速进行维修,系统还可以自动记录维修过程和结果,为后续的维修工作提供参考,该系统还可以提供数据分析功能,帮助纺织厂更好地了解客户需求和市场趋势。

作为纺织厂的保修工,他们肩负着确保产品质量和客户满意度的重任,他们需要具备专业的技能和知识,能够准确判断问题所在并提供有效的解决方案,他们还需要不断提高自己的专业技能和知识水平,以适应行业发展的需要,通过采取以上措施,纺织厂可以更好地履行职责、提高产品质量和客户满意度。

Articles related to the knowledge points of this article:

The Legacy of Luxury:A Journey Through Fotan Textiles

The Story of Dongguan Jiangnan Textile Factory

A Day in the Life of a Textile Mill

Exploring the Transformations at Huaibin Textile Factory in 2023