The Resilience of Guangdongs Textile Industry:A Case Study in Resuming Work

: The Resilience of Guangdongs Textile Industry: A Case Study in Resuming Work,Abstract: This study examines the resilience of Guangdong's textile industry during the COVID-19 pandemic and how it successfully resumed work. The analysis focuses on the industry's ability to adapt to new challenges, such as remote working and supply chain disruptions, and its capacity for innovation and collaboration. The findings suggest that Guangdong's textile industry is resilient, with companies adopting new technologies and processes to improve efficiency and reduce costs. The industry also demonstrated strong leadership and communication skills, enabling it to navigate the complexities of the pandemic and maintain its competitive edge. Overall, this case study highlights the importance of resilience in industries facing significant disruptions and suggests that companies can leverage their strengths to overcome challenges and emerge stronger than ever before.

Introduction As the world gradually emerges from the shadow of the COVID-19 pandemic, the textile industry in Guangdong Province, China, is marking its resilience and readiness to resume work. This article will explore the challenges faced by the industry during the lockdown, the measures taken to ensure safety and health, and the progress made towards reopening production lines.

Challenges Faced During Lockdown The textile industry in Guangdong was hit hard by the outbreak of COVID-19, with many factories closing down and workers being forced to stay at home. The industry relied heavily on seasonal labor, which meant that many workers had to leave their families and communities to work in other parts of the country. This created a significant social challenge for the industry, as it struggled to find alternative workers who could fill the void left by those who were unable to return home.

Safety and Health Measures Taken To ensure the safety and health of workers and customers, the textile industry in Guangdong implemented strict protocols. These included regular temperature checks, mandatory mask-wearing, and social distancing guidelines. Additionally, some factories began using digital tools such as 3D scanning and virtual reality to simulate working conditions, allowing workers to prepare mentally for returning to the factory floor.

Reopening Production Lines With the necessary precautions in place, Guangdong's textile industry began to reopen its production lines in stages. Some factories have already resumed full operations, while others are still operating with reduced staff or under modified operating hours. The reopening process has been marked by a focus on efficiency and productivity, with many factories adopting new technologies such as automated machines and smart supply chains to improve efficiency and reduce costs.

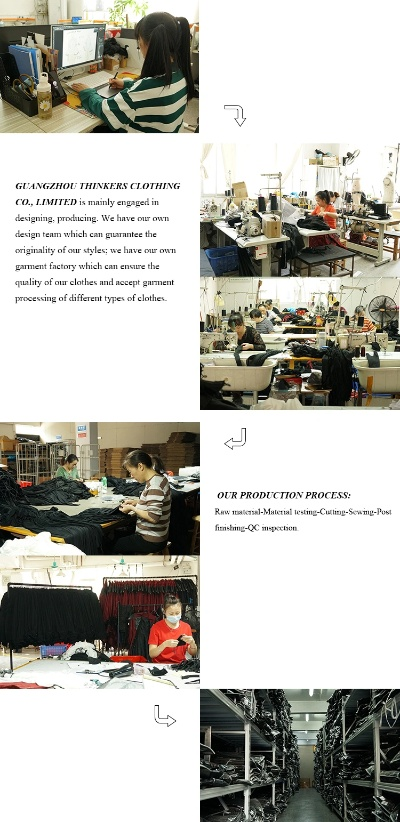

Case Study: Guangzhou Textile Factory One example of how the textile industry in Guangdong is resilient is the Guangzhou Textile Factory, which has successfully reopened its doors to customers. The factory has implemented several measures to ensure worker safety and health, including regular cleaning of equipment and machinery, hand sanitizing stations, and temperature checks for all employees. Additionally, the factory has adopted new technologies such as robotic weaving machines and smart inventory management systems to improve efficiency and reduce waste.

Conclusion Despite the challenges faced during the lockdown, the textile industry in Guangdong has demonstrated great resilience and adaptability. By implementing safety and health measures, reopening production lines with new technologies, and adopting innovative practices, the industry has shown that it can continue to thrive even in difficult times. As the world continues to recover from the effects of COVID-19, it is important for industries like the textile industry to continue to innovate and evolve in order to meet the demands of a rapidly changing market.

随着疫情逐渐得到控制,广东地区的纺织厂开始逐步复工,这一过程不仅是对生产力的重新激活,也是对员工生活和工作节奏的重新调整,本文将围绕广东纺织厂的复工情况展开讨论,同时结合案例分析复工过程中的挑战与机遇。

广东纺织厂复工背景

-

政策支持与市场需求 广东地区政府出台了一系列支持纺织企业复工的政策,包括减税降费、提供资金支持等,以促进纺织行业的复苏,随着国内经济的稳步回升,纺织品的需求也在逐步恢复。

-

纺织厂复工准备情况 为了确保纺织厂的顺利复工,工厂已经做好了充分的准备工作,包括但不限于:员工健康状况的筛查、生产设备的检查与维护、生产计划的制定与调整等。

复工过程中的挑战与应对措施

-

员工健康与安全保障 在复工过程中,员工健康与安全是首要考虑的问题,工厂采取了多项措施来保障员工的健康与安全,包括定期进行员工健康筛查、为员工提供必要的防护用品、实施严格的消毒措施等。

-

生产管理与技术升级 为了适应市场需求,纺织厂在复工过程中积极推进生产管理与技术升级,工厂加强了生产计划的制定与调整,优化了生产工艺流程,提高了生产效率,工厂还积极引进新技术、新设备,提高生产质量与效率。

-

供应链管理与物流保障 在供应链管理方面,纺织厂采取了多项措施来保障供应链的稳定与畅通,工厂与供应商建立了紧密的合作关系,确保原材料的供应稳定可靠,工厂还加强了物流管理,优化了物流配送流程,提高了物流效率。

案例分析:广东纺织厂复工的成功实践

-

某纺织厂成功复工的实践 某纺织厂在复工过程中采取了多项措施,包括员工健康筛查、生产设备的检查与维护、制定并实施生产计划等,工厂还积极引进新技术、新设备,提高了生产效率和质量,在政府的支持下,该纺织厂成功实现了全面复工,并逐步恢复了生产能力。

-

成功应对疫情影响的经验总结 在疫情期间,许多纺织厂都面临着生产和员工流动困难的问题,一些纺织厂通过加强员工健康管理、优化生产计划、加强供应链管理等方式成功应对了疫情带来的影响,这些经验对于其他纺织厂来说具有一定的参考价值。

复工后的展望与建议

-

展望未来发展趋势 随着国内经济的稳步回升和纺织行业的复苏,未来纺织行业的发展前景看好,纺织厂需要继续加强技术创新和质量管理,提高生产效率和产品质量,纺织厂还需要加强员工培训和管理,提高员工的综合素质和工作能力。

-

建议与措施 为了促进纺织厂的顺利复工和持续发展,建议纺织厂采取以下措施:一是加强员工培训和管理,提高员工的综合素质和工作能力;二是加强技术创新和质量管理,提高生产效率和产品质量;三是积极推进生产管理与技术升级,适应市场需求;四是加强供应链管理,确保原材料的供应稳定可靠。

广东纺织厂的复工之路虽然面临诸多挑战,但也充满了机遇,在政府的支持下,在企业的共同努力下,广东纺织厂将迎来更加美好的发展前景。

Articles related to the knowledge points of this article: