A Comprehensive Overview of Textile Dyeing Machines

This article provides a comprehensive overview of textile dyeing machines. It discusses the different types of dyeing machines, including batch, continuous, and overhead machines, and their respective applications in the textile industry. The article also highlights the importance of choosing the right machine for the job, taking into account factors such as colorfastness, fastness, and cost. Additionally, it discusses the various materials used in dyeing machines, including dyes, fixatives, and auxiliaries, and their impact on the final product's quality. Finally, the article looks at the future of textile dyeing machines, highlighting emerging technologies that are expected to revolutionize the industry. Overall, this article provides readers with a thorough understanding of the various aspects of textile dyeing machines, making it an essential read for anyone involved in the textile industry.

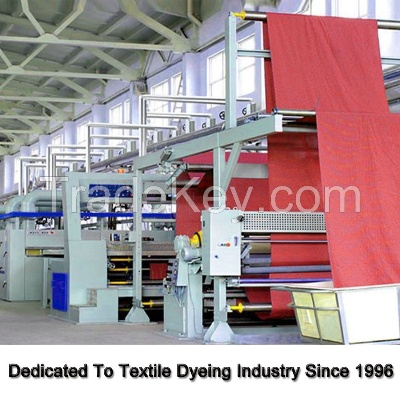

In the textile industry, dyeing machines play a crucial role in transforming raw materials into finished products. With advancements in technology and changing consumer preferences, there are now a wide range of dyeing machines available for different types of textiles. In this article, we will discuss some of the most popular textile dyeing machines and their applications.

-

Dry Bed Dyebathers

- Dry bed dyeing machines are used for printing on cotton, linen, and other natural fibers. These machines use a hot air system to dry the fabric after dyeing.

- Example: The Xerox ColorCraft 2500 is a popular dry bed dyeing machine that can process up to 1000 meters of fabric per hour.

-

Wet-Bed Dyebathers

- Wet-bed dyeing machines are used for printing on synthetic fibers such as polyester, nylon, and acrylic. These machines use a chemical bath system to dye the fabric.

- Example: The Tetrad 3000 wet-bed dyeing machine is designed for high-volume production and can process up to 1000 meters of fabric per hour.

-

Entrapped Dyeing Machines

- Entrapped dyeing machines are used for printing on cotton and other natural fibers. These machines use a special entrainment technique to apply dye directly onto the fabric.

- Example: The Encore 4000 entrapped dyeing machine is a versatile machine that can be used for both wet and dry processes.

-

Steam Jet Dyebathers

- Steam jet dyeing machines use steam to remove excess water from the fabric after dyeing. This process helps to improve the quality of the dyed product.

- Example: The C&M Sjöström 8000 steam jet dyeing machine is a large-scale machine that can handle high volumes of fabric.

-

Electrostatic Dyebathers

- Electrostatic dyeing machines use electrostatic forces to apply dye onto the fabric. These machines are often used for small-batch production or for specialty applications.

- Example: The ECOLON EC 6000 electrostatic dyeing machine is a compact machine that can handle small quantities of fabric.

-

Heat Press Dyebathers

- Heat press dyeing machines use heat to fix the dye onto the fabric. This process is often used for printed fabrics that need to withstand wear and tear.

- Example: The Heidelberg Printex 2000 heat press dyeing machine is a popular choice for small businesses that need to produce high-quality printed fabrics.

-

Laser Dyebathers

- Laser dyeing machines use laser technology to apply dye onto the fabric. These machines are often used for high-precision printing applications.

- Example: The Epilog Epilog 3000 laser dyeing machine is a versatile machine that can handle both wet and dry processes.

In conclusion, there are many different types of textile dyeing machines available for different types of textiles. By understanding the different techniques and machines available, textile manufacturers can choose the right one for their specific needs.

纺织品染色机品种概述

纺织品染色机是用于将各种纤维材料染色加工的设备,种类繁多,涵盖了从基础色染到特殊工艺染色等多个领域,根据不同的工艺需求和产品特点,纺织品染色机可以分为多种不同的品种。

主要染色机品种介绍

活性染料染色机

活性染料染色机是一种高效、环保的染色设备,适用于各种纤维材料的染色,其特点在于能够根据纤维材料的性质和染色要求,选择合适的活性染料进行染色,活性染料染色机通常采用先进的染色技术,能够提供丰富的颜色选择和较高的染色牢度。

英文案例说明:近年来,随着环保意识的提高和消费者对绿色纺织品的追求,活性染料染色机在市场上越来越受欢迎,某知名纺织品企业采用先进的活性染料染色机,成功生产出了一系列具有高色牢度、环保特点的纺织品,受到了市场的广泛好评。

连续式染色机

连续式染色机是一种高效、连续的染色设备,适用于大规模生产,其特点在于能够根据生产需求,连续进行染色加工,提高了生产效率,连续式染色机通常采用自动化控制系统,能够实现自动化操作和智能化管理。

英文案例说明:某大型纺织品企业采用连续式染色机进行大规模生产,实现了高效、稳定的生产效果,该设备能够适应不同纤维材料的染色需求,能够满足不同客户的需求定制化生产,连续式染色机的自动化控制系统也大大提高了生产效率和管理水平。

半自动染色机

半自动染色机是一种适合中小型生产企业的设备,具有较高的灵活性和适用性,其特点在于能够根据生产需求进行半自动操作,降低了人工成本,半自动染色机通常采用简单的工艺流程和操作方式,适用于初学者或小型企业的使用。

案例分析

以某知名纺织品企业为例,其采用了多种不同类型的纺织品染色机进行生产,活性染料染色机和连续式染色机是其主要的染色机品种之一。

-

活性染料染色机案例分析:该企业采用先进的活性染料染色机进行生产,成功生产出了一系列具有高色牢度、环保特点的纺织品,该设备能够根据纤维材料的性质和染色要求,选择合适的活性染料进行染色,能够提供丰富的颜色选择和较高的染色牢度,该设备还具有自动化控制系统和智能化管理功能,提高了生产效率和产品质量。

-

连续式染色机案例分析:该企业采用连续式染色机进行大规模生产,实现了高效、稳定的生产效果,该设备能够适应不同纤维材料的染色需求,能够满足不同客户的需求定制化生产,该设备的自动化控制系统也大大提高了生产效率和管理水平,该企业还采用了先进的节能环保技术,降低了生产成本和环境污染。

纺织品染色机的品种繁多,每种机型都有其独特的适用范围和特点,在选择纺织品染色机时,需要根据实际的生产需求和产品特点进行选择,随着纺织行业的发展和技术的不断进步,纺织品染色机的品种和性能也在不断升级和完善,纺织品染色机将会更加注重环保、节能、智能化等方面的应用和发展。

Articles related to the knowledge points of this article: