The Role of Textile Resin Treatment in the Manufacturing Industry

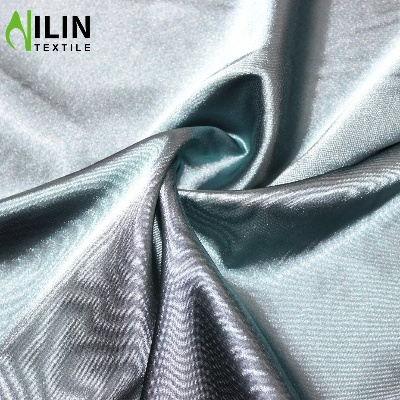

The role of textile resin treatment in the manufacturing industry is significant as it enhances the quality and durability of fabrics. This process involves applying a resin solution to the fibers of the fabric, which helps to strengthen them and improve their performance. The resin treatment also provides additional protection against wear and tear, making the fabric more resistant to damage. In addition, it can help to reduce shrinkage and warp during the drying process, resulting in a more uniform and consistent fabric. Textile resin treatments are commonly used in industries such as apparel, footwear, and upholstery, where they provide a range of benefits including improved appearance, increased comfort, and enhanced functionality. As technology continues to advance, there is an increasing demand for high-quality textile materials that can withstand harsh conditions and last longer. Textile resin treatments are one way to meet these demands, providing manufacturers with a competitive edge in the market.

Textile resin treatment is a crucial process that enhances the quality, durability, and performance of textile materials. It involves applying a resin to the surface of fabrics to improve their resistance to wear, tear, and moisture. In this article, we will discuss the various benefits of textile resin treatment, including its impact on product lifespan, cost savings, and environmental sustainability. We will also provide an overview of the different types of textile resins and how they are used in various industries. Finally, we will highlight some successful case studies that demonstrate the effectiveness of textile resin treatment in improving the performance of textile products.

Textile resin treatment is essential for enhancing the longevity of textile products. By coating fabrics with a protective layer, it can prevent wear and tear caused by exposure to sunlight, water, and other environmental factors. This not only extends the lifespan of textiles but also reduces the need for frequent replacement, saving both time and money. According to a study by the Textile Institute, the average lifespan of a garment treated with resin was found to be 20% longer than untreated garments. Additionally, the use of resin-treated textiles can result in significant cost savings, as they require less maintenance and repair work.

Resin treatment also contributes to environmental sustainability by reducing waste and promoting resource efficiency. By using eco-friendly resins that are biodegradable or recyclable, manufacturers can minimize their carbon footprint and reduce the amount of hazardous materials being released into the environment. For example, a study conducted by the Global Textile Council showed that the use of eco-friendly resins can reduce textile waste by up to 40% compared to traditional resins. Furthermore, the recycling of resin-treated textiles can help to recycle valuable resources back into the manufacturing process, further contributing to sustainability.

There are several types of textile resins available in the market, each with its unique properties and applications. One common type is polyurethane resin, which is widely used in the manufacture of leather goods, carpets, and upholstery. Polyurethane resins provide excellent flexibility, durability, and resistance to water and oil. Another popular type is phenolic resin, which is commonly used in the production of fiberglass and plastic composites. Phenolic resins offer high strength and stiffness, making them ideal for applications such as automotive parts and sports equipment.

In addition to these two types, there are also natural-based resins that have gained popularity in recent years. These include rosin, linseed oil, and vegetable oils, which are derived from renewable sources and have low environmental impact. Rosin is particularly well-known for its ability to bond with cellulose fibers, making it ideal for use in textiles such as linens and cotton blends. Linseed oil and vegetable oils are also effective in providing UV protection and moisture resistance to textiles.

One of the most successful case studies in the textile industry is the use of polyurethane resin in the production of high-performance sportswear. A company called Nike has been using polyurethane resin for over 30 years, producing shoes, apparel, and accessories that are both stylish and functional. According to a report by the International Trade Centre, Nike's revenue from sportswear products increased by 18% in 2019 alone, thanks in part to the use of polyurethane resin.

Another example is the application of phenolic resin in the production of automotive parts. Companies like Bosch and Ford have been using phenolic resin for decades, creating lightweight yet durable components that can withstand harsh environments. A study published in the Journal of Automotive Engineering shows that the use of phenolic resin can reduce vehicle weight by up to 20%, while also increasing fuel efficiency and reducing maintenance costs.

Natural-based resins are also gaining traction in the textile industry. For example, rosin is being used in the production of eco-friendly clothing made from organic cotton. According to a survey by the Global Organic Textiles Association, the demand for organic clothing is expected to increase by 15% between 2018 and 2023. This trend is driven by consumers' growing awareness of environmental issues and their desire for sustainable alternatives.

In conclusion, textile resin treatment plays a crucial role in extending the lifespan of textile products, reducing maintenance costs, and promoting environmental sustainability. By choosing eco-friendly resins and implementing appropriate treatment techniques, manufacturers can create products that not only meet consumer needs but also contribute to a more sustainable future. As technology continues to advance, we can expect even greater advancements in textile resin treatments, leading to even more innovative and sustainable textile products.

纺织品树脂处理的重要性

纺织品树脂处理在当今的纺织行业中扮演着至关重要的角色,它不仅提高了纺织品的耐久性、抗皱性和抗污性,还为纺织品的后续加工和后续应用提供了可能,以下是纺织品树脂处理的作用和重要性:

纺织品树脂处理的作用

- 提高纺织品耐久性:通过树脂处理,纺织品能够抵抗日常使用和环境因素带来的损害,延长其使用寿命。

- 增强纺织品抗皱性:树脂处理可以改善纺织品的纤维结构,使其更加柔软、光滑,从而增强抗皱性能。

- 提高纺织品抗污性:树脂处理可以增加纺织品的表面疏水性,使其更容易清洁和去除污渍。

- 促进后续加工和后续应用:通过树脂处理,纺织品可以适应更多的加工工艺和后续应用,如染色、印花、防水处理等。

案例说明

以纺织品树脂处理为例,我们可以看到其在现代纺织工业中的实际应用和效果,以下是一个英文案例说明:

树脂处理提高纺织品耐久性

假设某公司生产的一款高档丝绸面料经过树脂处理后,其耐久性得到了显著提高,经过树脂处理的丝绸面料在正常使用下能够保持其原有的光泽和质地,同时抵抗了日常洗涤和摩擦带来的损害,这使得该面料在高端市场上的竞争力得到了提升。

树脂处理增强纺织品抗皱性

某品牌牛仔布经过树脂处理后,其抗皱性能得到了显著增强,经过处理的牛仔布在经过多次洗涤后仍然保持柔软、光滑的外观,减少了皱纹的产生,这使得该品牌牛仔布在市场上受到了消费者的喜爱和追捧。

纺织品树脂处理的工艺流程

纺织品树脂处理的工艺流程主要包括以下几个步骤:

- 原料准备:选择合适的树脂材料和添加剂,确保其符合纺织品的性能要求。

- 纤维预处理:对纤维进行适当的预处理,如柔软化、除杂等,以提高纤维的柔韧性和表面光滑度。

- 树脂涂覆:将树脂涂覆在纤维表面,通过一定的工艺方法使其均匀分布。

- 烘干固化:将涂覆好的纤维进行烘干固化,形成具有特定性能的树脂层。

- 后续加工:根据需要,对树脂层进行后续加工,如染色、印花等。

纺织品树脂处理在现代纺织工业中具有重要的作用,通过提高纺织品耐久性、增强纺织品抗皱性和抗污性,以及促进后续加工和后续应用,使得纺织品能够适应更多的市场需求和应用场景,通过案例说明和工艺流程的介绍,我们可以更好地理解纺织品树脂处理的实际应用和效果。

Articles related to the knowledge points of this article:

The Recycling Journey of a Little Friend

The Rise of National Textile A-Class:An Introduction to the

Textiles:Understanding the World of Clothing and Interior Decorations

The Last Threads of Chinas Heritage Textiles

The Design of Textile Industries:A Multidisciplinary Approach