The Art of Textured Printing:A Journey into the World of Textile Dispersion

"The Art of Textured Printing: A Journey into the World of Textile Dispersion" is a fascinating exploration of the intricate techniques and aesthetics that underlie textile dispersion printing. This process involves using a variety of materials, including inks, dyes, and additives, to create a unique pattern on fabrics, often resulting in highly detailed and visually stunning prints.,The journey begins with an understanding of the basic principles behind textile dispersion printing, which involve the use of specialized machines and chemicals to transfer patterns onto fabrics. As the process progresses, the focus shifts to the careful selection and application of different materials, each with its own unique properties and effects.,Through this journey, we gain a deeper appreciation for the beauty and complexity of textile dispersion printing, as well as the skilled craftsmanship required to achieve truly exceptional results. Whether working with natural fibers or synthetic materials, the possibilities are endless, and the possibilities for creativity are limitless.

Introduction: The world of textiles is a vast and diverse landscape, where creativity meets function. One of the most innovative techniques in this field is dispersion printing, which involves the use of small, discrete dye particles to create intricate patterns on fabric. In this article, we will explore the principles behind dispersion printing, its applications, and some inspiring case studies that showcase the beauty and functionality of this technique.

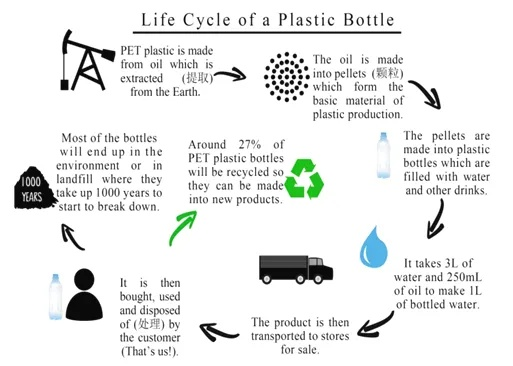

Dispersion Printing: The Science Behind It Dispersion printing is a process that involves mixing dyestuff with water, creating a homogeneous solution. This solution is then applied to a substrate, such as cotton or polyester, using a variety of techniques, including screen printing, pad printing, and airbrush painting. As the solvent evaporates, the dye particles settle onto the substrate, creating a pattern that can be seen under a microscope.

The key to successful dispersion printing lies in the careful selection of dyestuff and the precise control of the printing process. The right combination of dyestuff and solvent creates a stable emulsion that allows for even distribution of the dye particles across the substrate. Additionally, the speed at which the solvent evaporates affects the final color intensity and uniformity of the printed pattern.

Applications of Dispersion Printing: From Fashion to Textiles Dispersion printing has found numerous applications in the textile industry, from fashion to home decor. Here are just a few examples:

-

Fashion: Dispersion printing is used extensively in the fashion industry to create unique and eye-catching patterns on clothing. From trendy T-shirts to luxurious silk scarves, designers have taken full advantage of this technique to create designs that are both functional and aesthetically pleasing.

-

Home Decor: Dispersion printing is also used in the home decor industry to add texture and character to pillows, curtains, and other textiles. By incorporating small, intricate patterns into these items, designers create a sense of depth and dimensionality that is both soothing and visually appealing.

-

Sportswear: Dispersion printing is becoming increasingly popular in the sportswear industry, particularly for high-performance apparel like running shoes and cycling jerseys. By utilizing this technique, manufacturers are able to create designs that are both lightweight and durable, while still maintaining a stylish look.

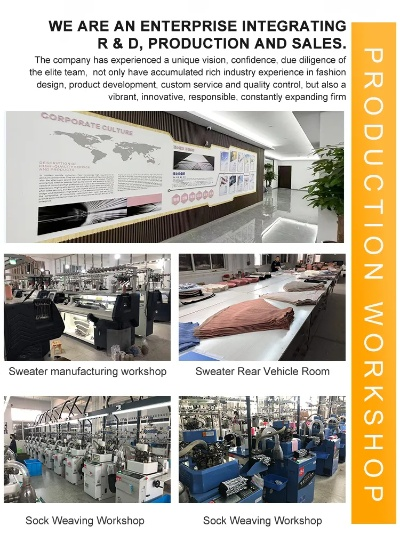

Case Study: The Future of Textiles with Dispersion Printing One company that has made significant strides in the realm of dispersion printing is Ralph Lauren. The American luxury brand has been experimenting with new designs using this technique for years, resulting in collections that are not only visually stunning but also functional. For example, one of their latest collections features a terrycloth bathrobe with a dispersion print that adds a playful touch to any bathroom setting.

Another company that has made a name for themselves in the dispersion printing world is Eileen Fisher. The American designer specializes in creating unique patterns on clothing and accessories using this technique. One of her most iconic pieces is a dress with a dispersion print that features a swirling seashell design, which is both elegant and whimsical.

Conclusion: Dispersion printing is more than just a fancy way of making clothes; it's a powerful tool for creating texture and depth in textiles. From fashion to home decor, from sportswear to everyday items, dispersion printing offers endless possibilities for designers and manufacturers alike. As technology continues to advance and demand for unique and personalized products rises, dispersion printing is poised to become an even more integral part of the textile industry. So next time you see something with a beautiful, intricate pattern on it, take a moment to appreciate the artistry behind it - it could be dispersion printing.

纺织品分散印花概述

纺织品分散印花是一种先进的纺织工艺,它利用特殊的分散技术将颜料、染料等分散在纤维表面,从而实现图案的印刷,这种工艺不仅提高了印花效率,还赋予了纺织品独特的纹理和色彩,在纺织品生产中,分散印花的应用越来越广泛,为消费者提供了更多选择和个性化定制的机会。

分散印花工艺流程

- 材料准备:选择高质量的纤维材料,确保其具有适当的柔软度和可塑性。

- 颜料和染料混合:根据设计要求,将颜料和染料按照一定比例混合,确保颜色均匀分布。

- 印花设备操作:使用专业的印花设备,将混合好的颜料和染料均匀地喷洒在纤维表面。

- 烘干处理:完成印花后,进行烘干处理,去除多余的水分。

- 后期处理:根据需要,可以对印花纺织品进行后续处理,如染色、印花图案修饰等。

案例分析

纺织品分散印花在时尚领域的运用

近年来,纺织品分散印花在时尚领域的应用越来越广泛,某品牌采用先进的分散印花技术,生产出具有独特纹理和色彩的服装面料,该面料采用了高质量的纤维材料,经过特殊的颜料和染料混合处理,实现了图案的印刷效果,该面料还具有透气性好、舒适度高、色彩鲜艳等特点,深受消费者喜爱。

纺织品分散印花在家居用品领域的创新

在家居用品领域,纺织品分散印花也取得了显著的成果,某公司采用先进的分散印花技术,生产出具有个性化定制功能的窗帘面料,该面料可以根据消费者的需求和喜好,定制不同的图案和颜色,满足了消费者对个性化定制的需求,该面料还具有环保、耐用等优点,受到了消费者的青睐。

分散印花工艺特点

- 高效率:采用先进的分散印花技术,可以实现快速、高效的印刷效果。

- 独特纹理和色彩:通过特殊的颜料和染料混合处理,可以实现独特的纹理和色彩效果。

- 环保可持续:采用环保材料和生产工艺,符合现代环保理念。

- 个性化定制:根据消费者的需求和喜好,可以实现个性化的图案和颜色定制。

英文表格补充说明

以下是英文表格补充说明:

| 英文术语 | 中文解释 |

|---|---|

| Textile Disperse Printing | 纺织品分散印花 |

| Material Preparation | 材料准备 |

| High-quality fiber material selected | 选择高质量的纤维材料 |

| Mixing of pigments and dyes | 颜料和染料的混合 |

| Process flow of dispersion printing | 工艺流程 |

| Step 1: Mixing of颜料和染料 | 准备混合颜料和染料 |

| Step 2: Operation of printing equipment | 使用印花设备进行操作 |

| Step 3: Drying treatment | 烘干处理 |

| Post-treatment options | 后期处理选项 |

| Example 1: Application of dispersion printing in fashion industry | 时尚领域案例一 |

| Example 2: Innovation in home textile industry with dispersion printing | 家居用品领域案例二 |

| Key features of dispersion printing | 分散印花工艺特点 |

| High efficiency | 高效率 |

| Unique texture and color | 独特纹理和色彩效果 |

| Environmental sustainability | 环保可持续性 |

| Personalization options | 个性化定制功能 |

| Example of modern technology usage in home textiles industry | 家居用品领域现代技术运用实例 |

结束语

纺织品分散印花作为一种先进的纺织工艺,具有高效、环保、个性化等特点,在纺织品生产中,其应用越来越广泛,为消费者提供了更多选择和个性化定制的机会,希望本文能够为读者提供有关纺织品分散印花的相关信息,为进一步了解纺织品生产提供帮助。

Articles related to the knowledge points of this article:

Understanding the Art and Science Behind Textile Production

The Fabric of Summer:A Look at Nantongs Summer Collection by NanTang Textiles