The Impact of Textile Materials Visual Defects on Quality and Durability

The study explores the impact of textile materials visual defects on quality and durability. The research found that defects such as color variations, wrinkles, and pilling can significantly affect the overall appearance and functionality of textile products. These defects can lead to reduced product appeal and consumer dissatisfaction. Additionally, visual defects can also impact the durability of textile materials, as they may cause wear and tear more quickly due to poor quality control during production. Overall, it is important for textile manufacturers to prioritize quality control measures to minimize the impact of visual defects on product performance and longevity.

Introduction Textile materials are an integral part of our daily lives, from clothing to furnishings. However, the quality and durability of these materials can be compromised by various external factors, including visual defects such as color variations, pilling, and wrinkles. In this article, we will explore the impact of textile materials' visual defects on quality and durability and provide insights into how they can be addressed through proper manufacturing processes and post-production treatments.

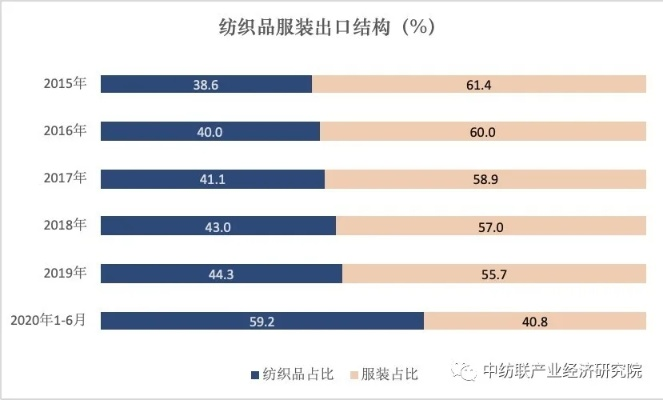

Color Variations Color variations in textile materials can result from a variety of factors, including dye lot variation, environmental factors like temperature and humidity, and even the wear and tear of the material over time. These variations can affect the aesthetic appeal and functionality of the product, making it difficult for consumers to make informed purchasing decisions.

For example, consider a case study involving a high-end fabric company that experienced significant color variations in their silk scarves during the production process. The company traced the problem back to a faulty dyeing machine that was not properly maintained. By implementing regular maintenance checks and upgrading the equipment, the company was able to reduce the occurrence of color variations and improve the overall quality of their products.

Pilling Pilling is a common issue in textile materials, particularly in synthetic fibers like polyester and nylon. Pilling occurs when small pieces of fiber protrude from the surface of the fabric, creating unsightly bumps or lumps. This not only affects the aesthetic appeal but also reduces comfort and breathability, making the fabric less functional.

To address this issue, manufacturers can use techniques like blocking or finishing with acrylic resin to prevent pilling. Additionally, they can incorporate anti-pilling agents into the fabric formulation to minimize pilling during the manufacturing process. By implementing these measures, manufacturers can enhance the durability and appearance of their products.

Wrinkles Wrinkles are another common defect in textile materials that can affect both the aesthetic appeal and functionality of the product. Wrinkles occur when the fabric is subjected to stress or friction, causing the fibers to fold or twist. This not only makes the fabric look unattractive but also reduces its durability and performance.

To prevent wrinkles, manufacturers can use techniques like pre-washing or pre-treatment to relax the fibers before sewing. They can also incorporate moisture-wicking properties into the fabric design to minimize wrinkling under normal conditions. Additionally, using advanced printing technologies like digital printing can help create smoother, more uniform patterns that reduce the risk of wrinkle formation.

Case Study: Textile Materials' Visual Defects Affecting Quality and Durability

Industry Example: Failure to Address Visual Defects Leads to Quality Issues

A recent report highlighted a case study involving a textile manufacturer that failed to address the visual defects in their cotton fabrics. The company produced high-quality garments with vibrant colors and smooth textures, but consumers reported experiencing significant creasing and pilling issues after washing. The manufacturer blamed the problem on the natural variability of the fabric and did not implement any corrective measures. As a result, the company faced reputational damage and decreased customer loyalty.

Lesson Learned: Addressing Visual Defects Enhances Product Quality and Durability

The failure of this manufacturer highlights the importance of addressing visual defects in textile materials. By implementing regular inspections, testing, and corrective actions, manufacturers can ensure that their products meet consumer expectations and maintain their brand reputation. Additionally, addressing visual defects early on can prevent costly recalls and damage to the manufacturer's reputation, ultimately benefiting both the company and its customers.

Conclusion Textile materials' visual defects can have a significant impact on quality and durability. By understanding the causes of these defects and implementing appropriate corrective measures, manufacturers can enhance the overall performance and appeal of their products. In conclusion, addressing visual defects is crucial for maintaining the quality and reputation of textile materials, ensuring that consumers receive high-quality products that meet their needs and expectations.

纺织品材料外观疵病概述

纺织品材料外观疵病是指纺织品在生产、加工过程中出现的各种不良外观现象,主要包括织物起皱、纱线断裂、色差、杂质等,这些疵病不仅影响纺织品的美观度和使用性能,还可能对产品质量和后续使用造成影响。

常见纺织品材料外观疵病类型

- 起皱:织物表面出现不规则的皱纹,可能是由于纤维材质、织造工艺、温度控制不当等因素引起的。

- 纱线断裂:纱线在织造过程中断裂,可能是由于纱线质量不佳、织造工艺不当、张力控制不当等因素引起的。

- 色差:纺织品颜色与标准色样不符,可能是由于染料批次不同、染色工艺不当、保管不当等因素引起的。

- 杂质:纺织品表面存在杂质,可能是原料不纯、加工过程中混入异物等。

英文案例说明

纺织品起皱问题

某品牌的一款丝绸面料在生产过程中出现了起皱问题,经过调查,发现是由于纤维材质较差,导致织造工艺不当引起的,针对这一问题,厂家采取了改进纤维材质、优化织造工艺的措施,并加强了生产过程中的质量控制,经过调整后,该问题得到了有效解决,产品外观得到了明显改善。

纱线断裂问题

某品牌的一款棉质衣物在加工过程中出现了纱线断裂问题,经过调查,发现是由于纱线质量不佳、织造工艺不当等因素引起的,厂家采取了提高纱线质量、优化织造工艺的措施,并加强了生产过程中的质量控制和检验,经过改进后,该问题得到了有效解决,产品质量得到了提高。

纺织品材料外观疵病原因分析

- 纤维材质问题:纤维材质是影响纺织品外观的重要因素之一,如果纤维材质较差,就会导致织物起皱、纱线断裂等问题。

- 织造工艺问题:织造工艺是影响纺织品外观的关键因素之一,如果织造工艺不当,就会导致织物表面出现不规则的皱纹、纱线断裂等问题。

- 温度控制不当:在纺织过程中,温度控制不当也会影响纺织品外观,如果温度过高或过低,就会导致织物起皱或纱线断裂等问题。

预防和解决纺织品材料外观疵病的方法

- 选用优质纤维材质:选用优质纤维材质是预防纺织品材料外观疵病的重要措施,应该选择符合国家标准、质量可靠的纤维材质,避免使用质量不佳的纤维材质。

- 优化织造工艺:优化织造工艺是解决纺织品材料外观疵病的关键措施,应该根据纺织品的特点和要求,选择合适的织造工艺,避免使用不当的织造工艺。

- 加强质量控制和检验:加强质量控制和检验是预防和解决纺织品材料外观疵病的重要手段,应该建立完善的质量控制和检验体系,对纺织品进行严格的检测和评估,及时发现和处理质量问题。

纺织品材料外观疵病是影响纺织品产品质量和使用性能的重要因素之一,为了预防和解决纺织品材料外观疵病,应该选用优质纤维材质、优化织造工艺、加强质量控制和检验等措施,还应该根据实际情况,采取针对性的措施,确保纺织品产品质量和使用性能达到要求。

Articles related to the knowledge points of this article:

The Textile Flagship:A Guide to Shopping for Quality Textiles

Can Textiles Qualify for Certificate of Conformity CCC)