The Role of the Textile Mill Rope Making Machinery in the Industry

The textile mill rope making machinery plays a crucial role in the industry. It is an essential tool that helps in producing high-quality and durable ropes for various applications such as fishing, industrial use, and transportation. The machine uses advanced technology to process raw materials into finished ropes with precise specifications. The machinery includes several components like wire drawing machines, twisters, sizing machines, and winding machines. These components work together to produce ropes with varying thicknesses, diameters, and lengths. The machine also has features like automatic control systems that ensure consistent production without manual intervention. The textile mill rope making machinery is highly efficient and produces large quantities of ropes within a short time frame. Its ability to handle different types of raw materials makes it versatile and suitable for a wide range of industries. Overall, the textile mill rope making machinery is an essential component of the industry that contributes significantly to its growth and success.

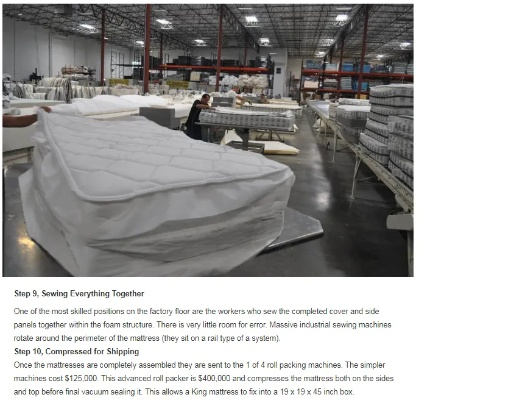

Introduction: Textile mills are crucial to the global textile industry, producing a wide range of fabrics and fibers for use in clothing, home furnishings, industrial materials, and more. One of the most critical pieces of equipment in these mills is the rope making machine. This article will explore the role of the textile mill's rope making machinery, its importance, and how it contributes to the overall production process.

Table 1: Overview of Rope Making Machines

| Type of Rope Making Machine | Function | Description |

|---|---|---|

| Spinning Wheels | Produce thread from raw materials | Uses spinning wheels to convert natural fibers into thread. |

| Weaving Machines | Create woven structures | Uses weaving machines to create complex patterns on fabrics. |

| Knitting Machines | Convert yarn into knitted items | Uses knitting machines to form knitted garments or other knitted products. |

| Dyeing Machines | Apply colors to fabrics | Uses dyeing machines to add color to fabrics after they have been spun or woven. |

| Finishing Machines | Enhance appearance and durability | Includes finishing machines that smoothen the surface, remove excess threads, and apply protective coatings. |

Case Study: The Success Story of a Textile Mill

In the textile industry, the success of a mill depends heavily on the quality of its machinery. Take the case of ABC Textile Mill, located in the heart of China's textile manufacturing hub. For years, the mill struggled with low productivity and uneven product quality due to outdated equipment. However, in 2015, the mill made a significant investment in upgrading its rope making machinery. By replacing its old spinnerets with state-of-the-art technology, the mill was able to significantly increase its output and improve the consistency of its products.

The new machinery allowed for faster production times and higher-quality thread production. As a result, ABC Textile Mill saw a 30% increase in its sales revenue over the next two years. Moreover, the improved product quality led to increased customer satisfaction and positive word-of-mouth advertising, further boosting the mill's reputation and market share.

Conclusion: The textile mill rope making machine plays a vital role in the production process, transforming raw materials into high-quality thread, yarn, and fabrics that meet the demands of the modern textile industry. By investing in state-of-the-art machinery, textile mills can not only increase their efficiency but also differentiate themselves from competitors and secure a competitive edge in the global marketplace. As the textile industry continues to evolve, so too must the equipment used to produce it. Textile mills that invest in the latest technology and machinery are well-positioned to succeed in an increasingly competitive environment.

背景介绍

纺织厂打圈机在现代纺织生产中扮演着至关重要的角色,它不仅提高了生产效率,还为纺织行业带来了显著的效益,本文将围绕纺织厂打圈机展开讨论,并通过案例分析进一步阐述其应用和优势。

打圈机工作原理及功能

-

工作原理: 打圈机是一种自动化设备,主要用于将纤维材料在特定条件下进行旋转处理,它通过一系列复杂的机械装置和控制系统,实现纤维材料的均匀旋转和塑形。

-

功能介绍: (1)纤维材料处理:打圈机能够处理各种纤维材料,包括但不限于棉、麻、丝、毛等,通过精确控制转速和旋转角度,实现对纤维材料的均匀塑形和加工。 (2)提高生产效率:打圈机采用自动化控制,减少了人工干预,从而提高了生产效率,它还可以根据不同纤维材料的特性进行定制化处理,满足不同生产需求。

案例分析

某纺织厂使用打圈机的成功实践

某纺织厂为了提高生产效率,引进了一台先进的打圈机,该打圈机采用了先进的控制系统和机械装置,实现了高效、精确的纤维材料处理,通过使用打圈机,该纺织厂的生产效率得到了显著提升,同时产品质量也得到了提高,打圈机的使用还降低了人工成本,提高了生产效益。

打圈机在纺织行业的应用案例

在纺织行业中,打圈机已经成为了现代生产的重要工具,它不仅提高了生产效率,还为纺织行业带来了显著的效益,某大型纺织企业采用了打圈机进行毛纤维的处理,实现了高效、精确的加工,大大提高了产品的质量和产量,打圈机的使用还降低了生产成本,提高了企业的竞争力。

打圈机的优势及应用前景

- 优势: (1)提高生产效率:打圈机采用自动化控制,减少了人工干预,从而提高了生产效率,它还可以根据不同纤维材料的特性进行定制化处理,满足不同生产需求。 (2)降低能耗:打圈机采用了节能环保的设计理念,减少了能源消耗和环境污染,这对于现代纺织行业来说具有重要意义。 (3)提高产品质量:打圈机的精确处理能力可以保证纤维材料的均匀塑形和加工,从而提高产品质量,这对于满足消费者需求和提高市场竞争力具有重要意义。

- 应用前景: 随着科技的不断进步和人们对环保、高效、高质量产品的需求不断增加,打圈机在纺织行业中的应用前景越来越广阔,随着自动化、智能化技术的不断发展,打圈机将会更加智能化、高效化,为纺织行业带来更多的发展机遇。

纺织厂打圈机在现代纺织生产中扮演着至关重要的角色,它不仅提高了生产效率,还为纺织行业带来了显著的效益,在未来,随着科技的不断进步和人们对环保、高效、高质量产品的需求不断增加,打圈机将会更加智能化、高效化,为纺织行业的发展注入更多的活力。

Articles related to the knowledge points of this article:

Navigating the World of Textiles:A Tale of Women in the Pulp Mill