The Fabrication of Quality:A Case Study on Deqing Yonghe Textile Mill

This study focuses on the quality control process of Deqing Yonghe Textile Mill, a leading textile manufacturer in China. The research aims to investigate how the mill manages to maintain high-quality products despite facing various challenges in production and supply chain management. The methodology employed involves an extensive review of company policies, procedures, and quality assurance measures. The findings reveal that Deqing Yonghe has implemented stringent quality control protocols, including regular audits, supplier evaluations, and employee training programs. Additionally, the mill has adopted modern technology, such as automated inspection systems and data analytics, to enhance its product quality. Despite these efforts, the study also highlights areas where further improvement is needed, such as improving communication among departments and enhancing flexibility in response to market demands. Overall, the case study demonstrates that by prioritizing quality in its operations, Deqing Yonghe has been able to establish a strong competitive edge in the textile industry.

Introduction: In the tapestry of global textile industry, Deqing Yonghe Textile Mill stands out as a beacon of excellence. This mill, nestled in the heart of China's Jiangsu province, is renowned for its meticulous craftsmanship and commitment to sustainability. Today, we delve into the fabrication process of this esteemed enterprise, highlighting its exceptional achievements and innovative strategies that have made it a leader in the industry.

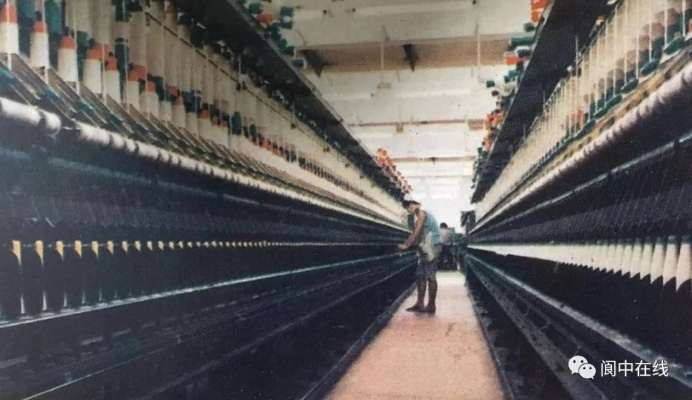

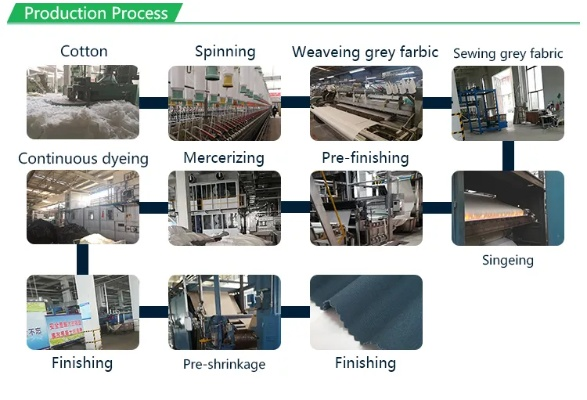

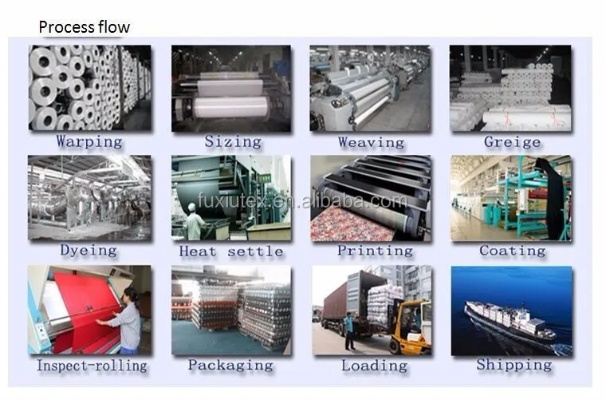

Production Process: The production process at Deqing Yonghe Textile Mill is a testament to the mill's dedication to quality. From raw materials to finished products, every step is carefully monitored to ensure that the final product meets the highest standards of excellence.

Materials: At the heart of any textile mill lies the raw materials. At Deqing Yonghe Textile Mill, these materials are sourced from reputable suppliers who prioritize sustainability and environmental responsibility. The mill uses high-quality yarns, fibers, and dyes that are specifically designed to withstand the rigorous conditions of the manufacturing process.

Manufacturing Process: Once the raw materials have been gathered, they are processed through a series of intricate steps. These include carding, spinning, weaving, and finally, finishing. Each stage is critical in ensuring that the final product is not only visually appealing but also functional and durable.

Carding: The first step in the manufacturing process involves carding, where the raw materials are broken down into shorter fibers. This process is essential in reducing the overall weight of the yarn, making it easier to handle and transport.

Spinning: Next comes spinning, where the carded fibers are spun into thread. The spinning process is critical in determining the strength and durability of the yarn, which will ultimately influence the quality of the final product.

Weaving: Once the yarn has been spun, it is then woven into fabric. Deqing Yonghe Textile Mill employs state-of-the-art machinery that allows for precise control over the weaving process, resulting in a seamless and uniform texture.

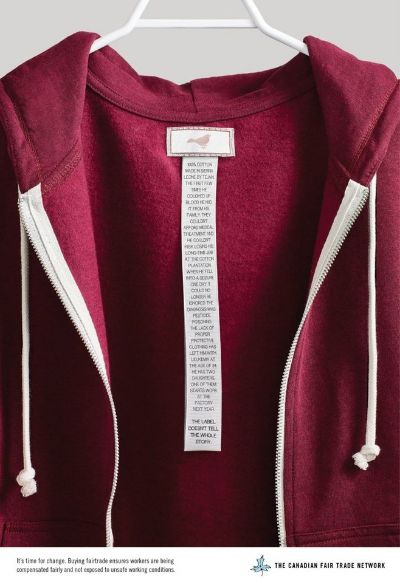

Finishing: Finally, the fabric undergoes finishing processes such as dying, cutting, and stitching. These processes enhance the overall appearance and functionality of the product, making it ready for distribution to customers worldwide.

Case Study: One of the most remarkable achievements of Deqing Yonghe Textile Mill is its commitment to using sustainable practices in its production process. The mill has implemented measures such as energy-efficient lighting, water recycling systems, and waste reduction programs to minimize its environmental impact.

Another notable aspect of the mill's operation is its focus on customer satisfaction. The mill takes pride in providing high-quality products that meet or exceed customer expectations. This approach has resulted in a loyal customer base and a reputation for excellence in the industry.

Conclusion: Deqing Yonghe Textile Mill stands as a shining example of how a textile mill can produce quality products while also being mindful of its impact on the environment. Through its meticulous production process and innovative strategies, the mill has established itself as a leader in the global textile industry. As we continue to witness the rise of sustainable practices in manufacturing, Deqing Yonghe Textile Mill serves as an inspirational benchmark for others to follow.

背景介绍

德清永和纺织厂,作为当地知名的纺织企业,以其精湛的工艺、先进的设备、丰富的产品种类以及良好的口碑在纺织行业独树一帜,该厂不仅在生产规模上不断扩大,而且在技术创新、环境保护等方面也取得了显著成就。

企业概况

- 企业名称:德清永和纺织厂

- 地理位置:位于德清县,交通便利,地理位置优越。

- 历史背景:该厂创立已有多年历史,凭借着精湛的工艺和良好的口碑赢得了广大客户的信赖和支持。

主要产品与服务

- 产品种类丰富:该厂主要生产各类纺织品,包括棉布、丝绸、麻布等,产品种类繁多,满足不同客户的需求。

- 生产工艺精湛:该厂采用先进的生产工艺和技术,确保产品质量稳定可靠。

- 环保理念:该厂注重环境保护,积极采用环保材料和技术,致力于打造绿色、环保的纺织企业。

企业成就案例

- 科技创新成果:近年来,该厂在科技创新方面取得了显著成果,该厂研发出一系列新型纺织材料,具有更好的耐热性、透气性和吸湿性,提高了产品的竞争力,该厂还积极采用智能化生产技术,提高了生产效率和产品质量。

- 环境保护实践:该厂注重环境保护,积极采用环保材料和技术,该厂在生产过程中严格控制废气、废水、废渣等污染物的排放,同时积极推广绿色生产模式,减少对环境的污染,该厂还加强了对员工环保意识的培训和教育,提高员工的环保意识。

- 成功案例分析:以某次重大订单为例,该厂成功满足了客户的需求,订单量大幅增长,该厂的产品质量也得到了客户的高度认可和好评,这一案例充分展示了该厂在纺织行业中的实力和影响力。

企业文化与价值观

- 企业文化:德清永和纺织厂秉承“质量为本、创新发展”的企业文化,注重员工培训和发展,不断提高员工的专业素质和创新能力,该厂注重环境保护和可持续发展,致力于打造绿色、环保的纺织企业。

- 价值观:该厂的价值观包括诚信、创新、质量、服务、责任等,诚信是该厂的基石,该厂始终坚持诚信经营,赢得广大客户的信任和支持,该厂注重技术创新和环保理念,不断提高产品质量和竞争力。

展望未来,德清永和纺织厂将继续秉承“质量为本、创新发展”的企业文化,不断加强技术创新和环保理念,提高产品质量和竞争力,该厂还将积极拓展市场,提高品牌知名度和影响力,该厂还将加强员工培训和发展,提高员工的综合素质和创新能力。

德清永和纺织厂作为当地知名的纺织企业,凭借着精湛的工艺、先进的设备、丰富的产品种类以及良好的口碑在纺织行业独树一帜,该厂将继续努力,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Beauty of a Textile Factory Girls Hair

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation