A Comprehensive Guide to Textile Dyeing and Finishing Techniques

This comprehensive guide provides an in-depth overview of textile dyeing and finishing techniques. It covers a wide range of topics, including the different types of dyes available, their applications, and how to select the right dye for your specific project. The guide also includes information on the various methods of dyeing, including pad, roller, and spray methods, as well as their respective advantages and disadvantages. Additionally, it covers the importance of pH control, temperature regulation, and proper rinsing procedures in achieving consistent results. Finally, the guide highlights the latest trends and developments in the textile industry, such as eco-friendly dyes and advanced finishing techniques. With its comprehensive coverage and practical tips, this guide is essential for anyone working with textiles, whether they are professionals or hobbyists.

Introduction: In the world of fashion and textiles, color is king. From the vibrant hues of a sports jersey to the sophisticated undertones of a designer gown, dyeing and finishing techniques play a crucial role in creating the final look. In this guide, we will explore the various methods used in dyeing and finishing textiles, from traditional hand-dyeing to modern machine-based processes. By the end of this tutorial, you will be equipped with the knowledge and skills to achieve stunning results on any project.

Part 1: Understanding Dyeing and Finishing Basics Before diving into the specific techniques, it's essential to understand the basic principles of dyeing and finishing. Dyeing refers to the process of applying colorants to fabric, while finishing involves enhancing the appearance of the dyed fabric by adding additional treatments such as washing, bleaching, and finishing agents.

Table 1: Overview of Dyeing and Finishing Processes | Process | Description | | -------- | ------------ | | Hand Dyeing | A labor-intensive method that involves manually applying dye directly to fabric using natural or synthetic dyestuffs. | | Machine Dyeing | Uses industrial dyeing machines to apply dye to fabric at high speeds and consistency. | | Washing | A cleaning step that removes excess dye and allows for even application of subsequent finishes. | | Bleaching | A chemical treatment that removes unwanted colorants, leaving behind lighter shades. | | Finishing Agents | Additives used to enhance the appearance of the dyed fabric, such as fixatives, softeners, and anti-static agents. |

Case Study: The Art of Hand Dyeing One of the most cherished aspects of hand dyeing is the ability to create unique and personalized pieces. Let's take a look at how one artist transformed a simple cotton shirt into a work of art using hand dyeing techniques.

Step 1: Preparation The first step in hand dyeing is preparing the fabric. This involves selecting the appropriate dyestuff, ensuring the fabric is clean and free of any dirt or oils that could interfere with the dyeing process.

Step 2: Applying Dye Using a brush or sponge, the artist applies the dye directly to the fabric. They carefully control the amount of dye applied to ensure even coverage without leaving any streaks or blotches.

Step 3: Rinsing and Drying After dyeing, the fabric is rinsed thoroughly to remove any excess dye and then allowed to dry naturally. This step ensures that the dye adheres properly to the fabric fibers.

Step 4: Final Treatments To enhance the appearance of the dyed fabric, the artist may add finishing agents such as waxes, oils, and pigments. These treatments help to protect the dye and provide a glossy finish.

Conclusion: Dyeing and finishing techniques are not only important for achieving a beautiful color but also for enhancing the durability and quality of the finished product. By understanding the basics of these processes and mastering the techniques involved, anyone can turn their textile projects into works of art. So grab your dyebath, gather your supplies, and get ready to create some truly stunning textiles!

大家好,今天我们将一起探讨纺织品染色整理的教程视频,通过这个视频,我们将深入了解纺织品染色整理的工艺流程、技巧和方法,我们还将通过实际案例来加深理解,以便更好地掌握染色整理技巧。

纺织品染色整理的基本原理

纺织品染色整理的基本原理主要包括染色剂的选择、染料与纤维的结合力、温度与湿度控制等,染色剂的选择应根据纤维类型和织物要求来确定,确保染料与纤维的结合力强,同时还要注意温度和湿度的控制,以避免染料褪色或变形。 详解

(一)染色前的准备

- 纤维准备:了解纤维类型和织物要求,选择合适的染色剂。

- 染料选择:根据纤维类型和织物要求,选择合适的染料。

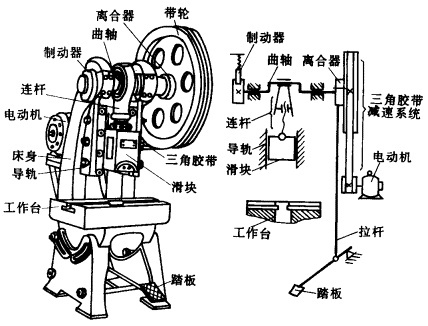

- 设备准备:准备好染色所需的设备,如染色机、搅拌器、加热器等。

(二)染色工艺流程

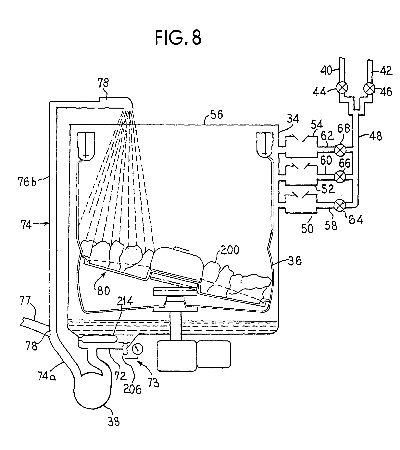

- 浸轧染色:将纤维放入染色机中,加入适量的染色剂,进行浸轧染色。

- 加热固色:在染色过程中,对纤维进行加热固色处理。

- 冷却定型:染料渗透到纤维内部后,进行冷却定型处理。

- 后续处理:根据需要,进行后续处理,如烘干、整理等。

(三)染色技巧与方法

- 选择合适的染色剂:根据纤维类型和织物要求,选择适合的染色剂,同时要注意染色剂的稳定性、色泽和耐洗性等指标。

- 控制温度与湿度:在染色过程中,要注意温度和湿度的控制,以避免染料褪色或变形,同时要根据纤维类型和织物要求,调整染缸内的湿度和温度。

- 搅拌均匀:在浸轧染色过程中,要确保染料充分均匀地渗透到纤维内部,可以使用搅拌器进行搅拌,使染料充分混合均匀。

- 观察染色效果:在染色完成后,要进行观察和评估,确保染色效果符合要求,同时要根据纤维类型和织物要求,调整染料的浓度和色泽等指标。

(四)案例分析

某品牌纺织品染色整理过程

该品牌采用特定的染色剂和工艺流程对纺织品进行染色整理,首先对纤维进行分类和处理,然后进行浸轧染色,并在染缸内进行加热固色处理,最后进行烘干和整理,最终得到色泽鲜艳、手感舒适的纺织品。

纺织品染色常见问题及解决方法

在实际操作中,纺织品染色可能会出现一些问题,如染料褪色、变形等,针对这些问题,我们可以采取一些解决方法,如选择合适的染色剂、控制温度与湿度、搅拌均匀等,同时我们还可以根据具体情况进行调整和处理。

通过这个视频和教程内容,我们了解了纺织品染色整理的基本原理、工艺流程、技巧和方法,同时我们还通过实际案例来加深理解,以便更好地掌握染色整理技巧,希望大家能够通过这个教程视频,掌握纺织品染色整理的技能和方法,为今后的纺织生产工作打下坚实的基础。

Articles related to the knowledge points of this article:

Bridging the Shanghai Textiles with the Power of Trading-Up Agent

The Industry Landscape of Textile Packaging:A Comprehensive Overview